Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Knurling Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

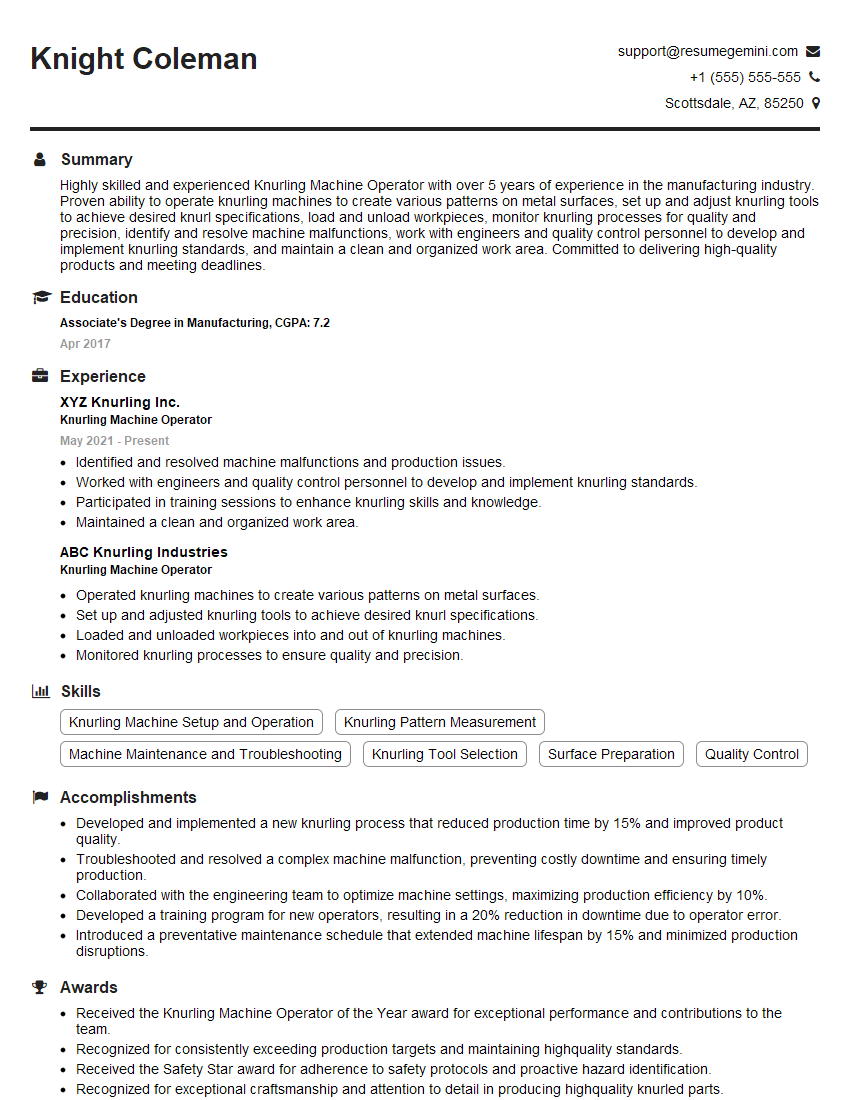

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Knurling Machine Operator

1. Describe the different types of knurling tools and their uses.

- Straight Knurling Tools: Create straight, parallel knurls with a consistent pattern.

- Diamond Knurling Tools: Produce diamond-shaped knurls for better grip and traction.

- Cross Knurling Tools: Form cross-hatched patterns for a decorative or functional finish.

2. How do you calculate the correct knurling pitch for a given application?

Knurl Pitch Formula:

- Pitch = (Number of teeth on knurling tool) / (Circumference of workpiece)

Factors to Consider:

- Material hardness

- Desired grip or traction level

- Workpiece size and geometry

3. What are the important factors to consider when selecting a knurling machine?

- Workpiece size and capacity

- Type of knurling tool used

- Precision and accuracy requirements

- Speed and feed ranges

- Safety features

4. Describe the process of setting up a knurling machine for operation.

- Mount the correct knurling tool

- Adjust the tool pitch and depth of cut

- Secure the workpiece and align it with the tool

- Set the desired speed and feed rates

- Calibrate the machine for accuracy

5. What are the common troubleshooting techniques for knurling operations?

- Inspect the knurling tool for wear or damage

- Check the workpiece material and hardness

- Ensure the machine is calibrated and working properly

- Adjust the tool pressure or feed rate

- Consider using a lubricant or cooling agent

6. Discuss the safety precautions that should be taken when operating a knurling machine.

- Wear proper safety gear, including gloves and eye protection

- Securely clamp the workpiece and ensure it is level

- Keep hands away from the rotating tool and workpiece

- Use a guard or shield to protect against flying chips

- Follow all manufacturer’s instructions and protocols

7. Explain the different methods of measuring knurl dimensions.

- Micrometer or Vernier Caliper: Measure the root, pitch, and crest diameters

- Knurl Comparator: Use a specialized tool to compare the knurl to a known standard

- Optical Comparator: Project the knurl image onto a screen for precise measurements

8. Describe the types of surface finishes that can be achieved with knurling.

- Diamond Knurl: Rough and aggressive finish for maximum grip

- Cross Knurl: Medium roughness for general-purpose applications

- Straight Knurl: Smooth finish for aesthetic or precise applications

9. How do you maintain a knurling tool for optimal performance?

- Sharpen the tool regularly to maintain sharpness

- Clean and lubricate the tool to reduce wear

- Inspect the tool for damage and replace it if necessary

- Follow the manufacturer’s recommended maintenance schedule

10. What are some advanced knurling techniques that you are familiar with?

- Double Knurling: Two passes of knurling for increased grip and durability

- Form Knurling: Rolling knurling for intricate patterns and shapes

- Orbital Knurling: Rotary motion for uniform and consistent knurls

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Knurling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Knurling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Knurling Machine Operators are responsible for the operation and maintenance of knurling machines. They produce knurled surfaces on cylindrical workpieces, using a variety of techniques.

1. Operating Knurling Machines

Knurling Machine Operators set up and operate knurling machines to produce knurled surfaces on cylindrical workpieces. They ensure that the machines are properly calibrated and adjusted to produce the desired results.

- Load and unload workpieces from the machine.

- Adjust the machine settings to produce the desired knurl pattern.

- Monitor the machine operation and make adjustments as necessary.

2. Maintaining Knurling Machines

Knurling Machine Operators perform regular maintenance on knurling machines to ensure that they are operating properly. They clean and lubricate the machines, and replace worn or damaged parts.

- Clean and lubricate the machine.

- Inspect the machine for worn or damaged parts.

- Replace worn or damaged parts.

3. Inspecting Knurled Surfaces

Knurling Machine Operators inspect knurled surfaces to ensure that they meet the required specifications. They use a variety of tools and techniques to inspect the surfaces, and they identify any defects or imperfections.

- Inspect knurled surfaces for defects.

- Identify any defects or imperfections.

- Reject workpieces that do not meet the required specifications.

4. Troubleshooting Knurling Machines

Knurling Machine Operators troubleshoot knurling machines to identify and resolve problems. They use their knowledge of the machines and their operation to diagnose problems and make repairs.

- Identify and resolve problems with knurling machines.

- Use their knowledge of the machines and their operation to diagnose problems.

- Make repairs to the machines.

Interview Tips

To prepare for an interview for a Knurling Machine Operator position, you should focus on your experience and skills in operating and maintaining knurling machines. You should also be prepared to discuss your knowledge of the different types of knurling machines and the different types of knurl patterns that can be produced.

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn about their history, products, and services.

- Read reviews of the company on websites like Glassdoor and Indeed.

- Talk to people in your network who work for the company.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” Practice answering these questions ahead of time so that you can deliver confident and well-thought-out responses.

- Make a list of common interview questions.

- Write out your answers to these questions.

- Practice saying your answers out loud.

3. Be Prepared to Discuss Your Experience and Skills

The interviewer will want to know about your experience and skills in operating and maintaining knurling machines. Be prepared to discuss your experience in detail, and highlight your skills and abilities.

- List your experience operating and maintaining knurling machines.

- Highlight your skills and abilities, such as your attention to detail and your ability to troubleshoot problems.

- Be prepared to answer questions about your experience and skills.

4. Ask Questions

At the end of the interview, you should ask the interviewer questions about the position and the company. This will show the interviewer that you are interested in the position and that you are serious about learning more about the company.

- Prepare a list of questions to ask the interviewer.

- Ask questions about the position, the company, and the industry.

- Be prepared to answer questions about your own questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Knurling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!