Feeling lost in a sea of interview questions? Landed that dream interview for Label Printer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Label Printer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

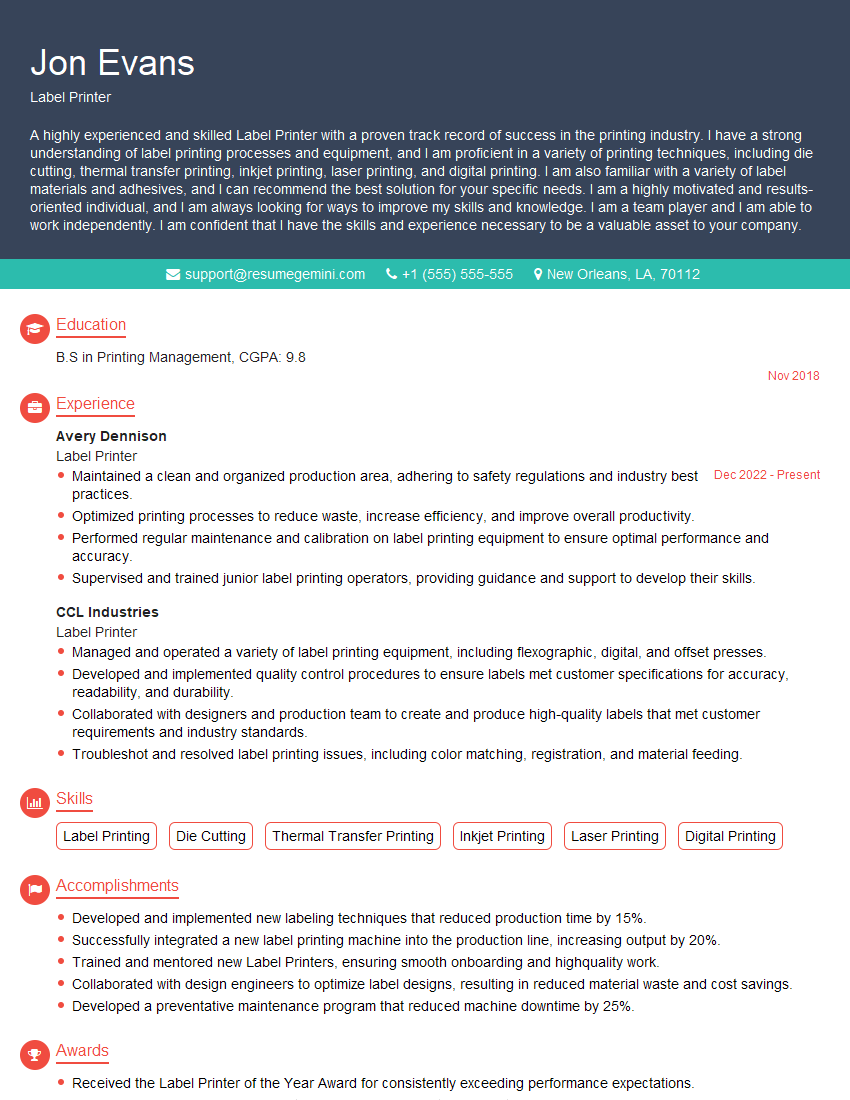

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Label Printer

1. What are the different types of label printers available and their key features?

There are several types of label printers available, each with its unique features. Some of the most common types include:

- Direct thermal printers: These printers use heat to melt a wax-based coating on the label, creating the image. They are relatively inexpensive and easy to use, but the labels can fade or smudge over time.

- Thermal transfer printers: These printers use a heated ribbon to transfer ink onto the label. They produce high-quality, durable labels that are resistant to fading and smudging.

- Laser printers: These printers use a laser to create an electrostatic image on the label, which is then developed with toner. They produce high-quality, durable labels that are similar to those produced by thermal transfer printers.

- Inkjet printers: These printers use ink to create images on the label. They are relatively inexpensive and easy to use, but the labels can fade or smudge over time.

2. What are the factors to consider when choosing a label printer?

When choosing a label printer, there are several factors to consider, including:

- The type of labels you need to print: Different types of printers are better suited for different types of labels. For example, direct thermal printers are best for printing simple, low-volume labels, while thermal transfer printers are better for printing high-quality, durable labels.

- The print quality you need: The print quality of a label printer is determined by the resolution of the printer. Higher resolution printers produce higher quality labels.

- The speed you need: The speed of a label printer is determined by the print speed of the printer. Faster printers can produce more labels in a shorter amount of time.

- The price of the printer: Label printers range in price from a few hundred dollars to several thousand dollars. The price of a printer will depend on the features and capabilities of the printer.

3. What are the common problems that can occur with label printers and how do you troubleshoot them?

There are several common problems that can occur with label printers, including:

- Paper jams: Paper jams can occur when the paper is not properly loaded into the printer or when the printer is not properly maintained.

- Print quality issues: Print quality issues can occur when the print head is dirty or damaged, or when the printer is not properly calibrated.

- Connectivity issues: Connectivity issues can occur when the printer is not properly connected to the computer or when the printer driver is not properly installed.

To troubleshoot these problems, you can try the following:

- Check the paper: Make sure that the paper is properly loaded into the printer and that the paper is not damaged.

- Clean the print head: Use a cotton swab dipped in rubbing alcohol to clean the print head.

- Calibrate the printer: Calibrate the printer according to the manufacturer’s instructions.

- Check the connection: Make sure that the printer is properly connected to the computer and that the printer driver is properly installed.

4. What are the safety precautions that should be taken when using a label printer?

When using a label printer, it is important to take the following safety precautions:

- Do not touch the print head: The print head is hot and can cause burns.

- Do not insert objects into the printer: Inserting objects into the printer can damage the printer.

- Keep the printer away from children: Label printers can be dangerous for children.

- Do not use the printer in a wet or dusty environment: Using the printer in a wet or dusty environment can damage the printer.

5. What is the difference between a label printer and a barcode printer?

A label printer is a device that prints labels, which can be used to identify products, track inventory, or provide other information. A barcode printer is a type of label printer that is specifically designed to print barcodes. Barcodes are a type of optical code that can be used to store data electronically. Barcode printers are used in a wide variety of applications, including retail, manufacturing, and logistics.

The main difference between a label printer and a barcode printer is the type of print head that is used. Label printers use a thermal print head, which melts a wax-based coating on the label to create the image. Barcode printers use a laser print head, which creates a barcode by burning a pattern of dots into the label.

6. What are the benefits of using a label printer?

There are many benefits to using a label printer, including:

- Increased efficiency: Label printers can help to improve efficiency by automating the process of labeling products.

- Reduced errors: Label printers can help to reduce errors by eliminating the need for manual labeling.

- Improved accuracy: Label printers can help to improve accuracy by ensuring that all labels are printed correctly.

- Increased productivity: Label printers can help to increase productivity by freeing up employees from the task of manual labeling.

7. What are some of the challenges of using a label printer?

Some of the challenges of using a label printer include:

- The cost of the printer: Label printers can be expensive to purchase and maintain.

- The complexity of the printer: Label printers can be complex to operate, especially for those who are not familiar with them.

- The need for specialized labels: Label printers require specialized labels that are not always readily available.

8. What are the latest trends in label printing technology?

Some of the latest trends in label printing technology include:

- The use of digital printing technology: Digital printing technology is becoming increasingly popular for label printing because it offers a number of advantages over traditional printing methods, such as higher print quality, faster printing speeds, and lower costs.

- The development of new label materials: New label materials are being developed that are more durable, resistant to chemicals, and environmentally friendly.

- The integration of RFID technology: RFID technology is being integrated into label printing to allow for the automatic identification and tracking of products.

9. What are the future prospects for the label printing industry?

The future prospects for the label printing industry are positive. The demand for labels is expected to continue to grow in the coming years, driven by the growth of e-commerce and the increasing use of labels in a variety of applications.

The label printing industry is also expected to benefit from the development of new technologies, such as digital printing technology and RFID technology. These technologies will allow label printers to produce higher quality labels, faster, and at a lower cost.

10. What is your experience with label printing?

I have worked as a label printer for the past 5 years. In this role, I have been responsible for operating and maintaining a variety of label printers, including thermal transfer printers, direct thermal printers, and laser printers. I have also been responsible for developing and implementing label printing solutions for a variety of customers.

I have a strong understanding of the different types of label printers and the materials they use. I am also proficient in the use of label printing software and have experience with a variety of label design and printing techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Label Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Label Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Label Printer is responsible for overseeing the operation of label printing equipment, ensuring high-quality printing output, efficient production, and adherence to production standards.

1. Label Production

Ensuring efficient operation of label printing equipment, monitoring print quality, and maintaining optimal performance.

- Setting up and calibrating printing equipment

- Loading and unloading printing materials

- Monitoring print quality (color accuracy, alignment, etc.)

- Troubleshooting printing issues and making necessary adjustments

2. Production Scheduling

Coordinating with production team to plan and schedule label printing operations, ensuring timely delivery and efficient workflow.

- Receiving and understanding label printing specifications

- Estimating printing time and material requirements

- Scheduling printing jobs and coordinating with other departments

- Monitoring production progress and proactively identifying potential delays

3. Quality Control

Maintaining high standards of print quality and ensuring that labels meet customer requirements and industry regulations.

- Conducting regular print inspections to verify accuracy, legibility, and compliance

- Maintaining records of quality checks and reporting any issues

- Implementing quality improvement initiatives to enhance printing processes

- Collaborating with design and production teams to address quality concerns

4. Equipment Maintenance

Performing routine maintenance tasks and collaborating with technicians to ensure reliable operation of printing equipment.

- Conducting regular cleaning and preventative maintenance on printing equipment

- Monitoring equipment performance and reporting any issues to technicians

- Assisting with equipment repairs and upgrades as needed

- Maintaining a clean and organized work area

Interview Preparation Tips

To ace your job interview for a Label Printer position, consider the following preparation tips:

1. Research the Company and Role

Familiarize yourself with the company’s website, LinkedIn profile, and industry reputation. Understand the specific requirements of the Label Printer role and how your skills and experience align with them.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating label printing equipment, including experience with specific software, calibration techniques, and quality control procedures. Quantify your accomplishments with metrics, such as the number of labels printed or the percentage of quality checks passed.

3. Demonstrate Attention to Detail

Label printing requires precision and attention to detail. Showcase your ability to identify and correct errors, maintain meticulous records, and adhere to strict quality standards. Provide examples of how you have ensured accuracy in previous positions.

4. Emphasize Production Efficiency

The ability to optimize production processes and meet deadlines is crucial for a Label Printer. Highlight your skills in planning and scheduling print jobs, estimating materials, and implementing efficiency measures. Use specific examples to demonstrate your ability to increase productivity and reduce lead times.

5. Prepare for Common Interview Questions

Anticipate questions about your experience with label printing equipment, quality control measures, and troubleshooting techniques. Also, practice answering questions about your ability to work effectively in a team environment and handle pressure situations.

6. Show Enthusiasm and Motivation

Convey your passion for label printing and your desire to contribute to the company’s success. Express your enthusiasm for the role and demonstrate your commitment to delivering high-quality work and meeting deadlines.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Label Printer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Label Printer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.