Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Label Rewinder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Label Rewinder so you can tailor your answers to impress potential employers.

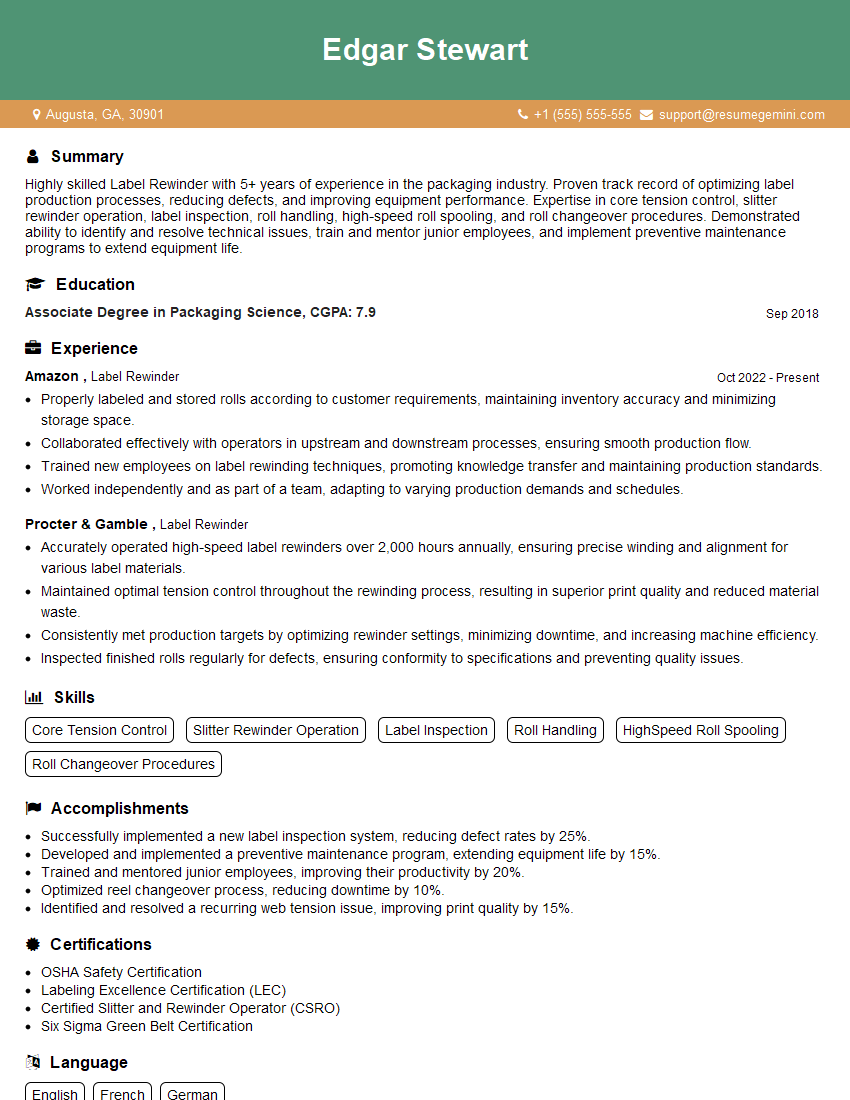

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Label Rewinder

1. What are the different types of label rewinders and what are their advantages and disadvantages?

- Shaftless rewinders: These rewinders do not require a shaft to hold the roll of labels, which makes them more versatile and easier to use. They are also more expensive than shaft rewinders.

- Shaft rewinders: These rewinders require a shaft to hold the roll of labels, which makes them less versatile and more difficult to use. They are also less expensive than shaftless rewinders.

2. What are the different tension control systems used in label rewinders and how do they work?

- Magnetic tension control: This system uses a magnetic field to control the tension of the label material. It is a very precise system, but it can be expensive.

- Mechanical tension control: This system uses a mechanical brake to control the tension of the label material. It is a less precise system than magnetic tension control, but it is also less expensive.

- Air tension control: This system uses air pressure to control the tension of the label material. It is a very precise system, but it can be more difficult to set up and maintain than other tension control systems.

3. What are the different types of web guides used in label rewinders and how do they work?

- Fixed web guides: These web guides are fixed in place and cannot be adjusted. They are used to guide the label material in a straight line.

- Adjustable web guides: These web guides can be adjusted to accommodate different widths of label material. They are used to guide the label material in a straight line and to prevent it from wrinkling or tearing.

- Dancing web guides: These web guides are mounted on a spring-loaded arm that allows them to move up and down with the tension of the label material. They are used to maintain a consistent tension on the label material and to prevent it from wrinkling or tearing.

4. What are the different types of slitters used in label rewinders and how do they work?

- Rotary slitters: These slitters use a rotating blade to cut the label material into strips. They are very fast and accurate, but they can be expensive.

- Guillotine slitters: These slitters use a guillotine blade to cut the label material into strips. They are less fast and accurate than rotary slitters, but they are also less expensive.

- Shear slitters: These slitters use a shear blade to cut the label material into strips. They are less fast and accurate than rotary slitters, but they are also less expensive.

5. What are the different types of rewinders used in label rewinders and how do they work?

- Shaftless rewinders: These rewinders do not require a shaft to hold the roll of labels, which makes them more versatile and easier to use. They are also more expensive than shaft rewinders.

- Shaft rewinders: These rewinders require a shaft to hold the roll of labels, which makes them less versatile and more difficult to use. They are also less expensive than shaftless rewinders.

6. What are the different types of label materials and how do they differ in terms of their properties?

- Paper labels: These labels are made from paper and are the most common type of label. They are inexpensive and easy to print on, but they are not very durable.

- Plastic labels: These labels are made from plastic and are more durable than paper labels. They are also more expensive and more difficult to print on.

- Metal labels: These labels are made from metal and are the most durable type of label. They are also the most expensive and the most difficult to print on.

7. What are the different types of adhesives used in label rewinders and how do they differ in terms of their properties?

- Water-based adhesives: These adhesives are made from water and are the most common type of adhesive used in label rewinders. They are inexpensive and easy to apply, but they are not very strong.

- Solvent-based adhesives: These adhesives are made from solvents and are stronger than water-based adhesives. They are also more expensive and more difficult to apply.

- Hot-melt adhesives: These adhesives are made from waxes and are the strongest type of adhesive used in label rewinders. They are also the most expensive and the most difficult to apply.

8. What are the different types of label printing technologies and how do they differ in terms of their capabilities?

- Flexography: This is a printing process that uses flexible printing plates to transfer ink to a substrate. It is a versatile printing process that can be used to print on a wide variety of materials.

- Gravure printing: This is a printing process that uses engraved printing plates to transfer ink to a substrate. It is a high-quality printing process that can produce very detailed images.

- Offset printing: This is a printing process that uses a metal printing plate to transfer ink to a rubber roller, which then transfers the ink to a substrate. It is a high-quality printing process that can produce very sharp images.

- Digital printing: This is a printing process that uses a computer to directly transfer ink to a substrate. It is a very versatile printing process that can be used to print on a wide variety of materials.

9. What are the different types of label finishing processes and how do they differ in terms of their capabilities?

- Die cutting: This is a process that uses a die to cut a label out of a roll of material. It is a versatile process that can be used to create a wide variety of shapes and sizes of labels.

- Slitting: This is a process that uses a slitter to cut a roll of material into individual labels. It is a fast and efficient process that can be used to produce a large number of labels.

- Laminating: This is a process that uses a laminating machine to apply a thin layer of plastic to a label. It is a durable process that can protect labels from moisture, dirt, and abrasion.

- Foil stamping: This is a process that uses a foil stamping machine to apply a thin layer of foil to a label. It is a decorative process that can make labels more attractive.

10. What are the different types of label inspection systems and how do they differ in terms of their capabilities?

- Manual inspection: This is a process that uses human inspectors to manually inspect labels for defects. It is a slow and inefficient process, but it is the most effective way to find defects.

- Automated inspection: This is a process that uses automated equipment to inspect labels for defects. It is a fast and efficient process, but it is not as effective as manual inspection.

- Semi-automatic inspection: This is a process that uses a combination of automated and manual inspection. It is a fast and efficient process, and it is more effective than manual inspection.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Label Rewinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Label Rewinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Label Rewinders operate machines that rewind and cut labels for various industries such as food, beverage, pharmaceuticals, and manufacturing. They ensure the smooth and efficient operation of the rewinders, inspect the quality of the labels, and maintain a clean and organized work area.

1. Operate Rewinding Machines

Load rolls of labels onto the rewinder and adjust the machine settings to the required specifications.

- Monitor the rewinding process to ensure proper tension, alignment, and diameter of the rewound rolls.

- Unload the rewound rolls and inspect them for defects.

2. Quality Control

Inspect labels for defects such as print quality, registration, and material flaws.

- Reject non-conforming labels and document the reasons for rejection.

- Maintain quality control records and report any issues to the supervisor.

3. Machine Maintenance

Perform routine maintenance on the rewinder, including cleaning, lubrication, and adjustments.

- Identify and troubleshoot minor mechanical issues.

- Request assistance from maintenance personnel for major repairs.

4. Safety and Housekeeping

Follow safety protocols and wear appropriate personal protective equipment.

- Maintain a clean and organized work area to prevent accidents.

- Dispose of waste materials properly.

Interview Tips

Preparing for a job interview as a Label Rewinder requires thorough research about the role and the company, practicing common interview questions, and showcasing your relevant skills and experience. Here are some tips to help you ace the interview:

1. Research the Role and Company

Understand the key responsibilities of a Label Rewinder and tailor your answers to the specific requirements of the job description.

- Visit the company’s website to learn about their products, services, and culture.

- Read industry publications to stay up-to-date on the latest trends and technologies.

2. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and motivation. Some examples include:

- “Tell me about your experience operating label rewinders.”

- “How do you handle quality control issues?”

- “What are your strengths and weaknesses as a Label Rewinder?”

3. Highlight Relevant Skills and Experience

Emphasize your technical skills, problem-solving abilities, and attention to detail. Quantify your accomplishments whenever possible.

- Use specific examples to demonstrate your proficiency in operating rewinders, inspecting labels, and maintaining equipment.

- Describe how you have improved quality control processes or reduced downtime.

4. Showcase Your Motivation

Explain your interest in the Label Rewinder role and how it aligns with your career goals. Express your enthusiasm for the industry and your eagerness to contribute to the company.

- Share your knowledge of the company’s products or services and how your skills can benefit their operations.

- Explain why you are passionate about the manufacturing process and quality control.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions related to the company’s growth plans, safety protocols, or opportunities for professional development.

- “What are the company’s plans for expanding its product line?”

- “How does the company prioritize safety in the workplace?”

- “Are there any opportunities for training or advancement within the company?”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Label Rewinder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Label Rewinder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.