Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Labeling Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Labeling Machine Operator so you can tailor your answers to impress potential employers.

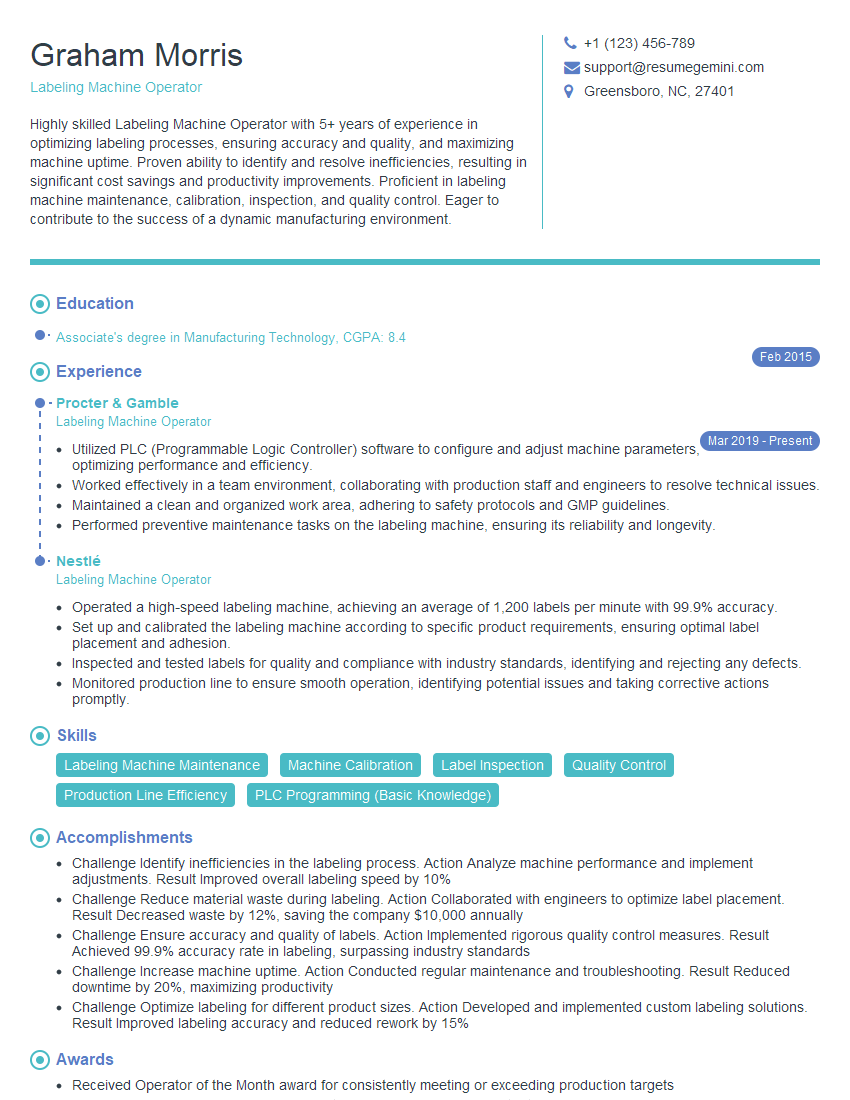

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Labeling Machine Operator

1. Explain the working principle of a labeling machine?

A labeling machine applies labels to products using various methods such as pressure-sensitive, heat-sensitive, or glue-based adhesives. The labeling process typically involves the following steps:

- Product detection: Sensors detect the presence of a product on the conveyor belt.

- Label dispensing: A label is dispensed from a roll or magazine onto the product.

- Label application: The label is applied to the product’s surface using a tamp, roller, or air blast.

- Label verification: Sensors or cameras check for proper label placement and quality.

2. Describe the different types of labeling machines and their applications?

Pressure-sensitive labelers:

- Use pressure to adhere labels to products.

- Suitable for labeling a wide range of products, including food, beverages, and pharmaceuticals.

Heat-sensitive labelers:

- Use heat to activate an adhesive on the label.

- Ideal for labeling products that require high resistance to moisture and temperature, such as glass bottles and metal cans.

Glue-based labelers:

- Apply a layer of glue to the label before applying it to the product.

- Used for labeling products with irregular shapes or surfaces.

3. What are the key factors to consider when selecting a labeling machine?

When selecting a labeling machine, the following factors should be considered:

- Product type and size

- Label type and material

- Labeling speed and accuracy requirements

- Production environment and space constraints

- Budget and availability of resources

4. Describe the routine maintenance tasks required for a labeling machine?

Routine maintenance tasks for a labeling machine include:

- Cleaning the machine and its components regularly

- Inspecting and replacing worn or damaged parts

- Calibrating sensors and ensuring accuracy

- Lubricating moving parts

- Checking electrical connections and wiring

5. Explain the importance of label quality and how to ensure it?

Label quality is crucial for product identification, branding, and compliance. To ensure label quality:

- Use high-quality label materials

- Properly store and handle labels

- Calibrate and maintain the labeling machine regularly

- Inspect labels for defects before applying them

6. Discuss the safety precautions to be observed when operating a labeling machine?

Safety precautions for operating a labeling machine include:

- Wearing appropriate safety gear

- Ensuring proper machine guarding

- Following lockout/tagout procedures

- Being aware of moving parts and potential pinch points

- Reporting any unsafe conditions or malfunctions

7. Explain how to troubleshoot common labeling machine problems?

Common labeling machine problems include:

- Label misalignment or wrinkles

- Label tearing or breakage

- Sensor malfunctions

- Mechanical failures

Troubleshooting steps may involve:

- Checking label alignment and tension

- Inspecting sensors and wiring

- Lubricating moving parts

- Consulting the machine’s manual

8. Describe the role of automation in labeling processes?

Automation plays a significant role in labeling processes by:

- Increasing speed and efficiency

- Reducing manual labor and errors

- Ensuring consistent label placement and quality

- Integrating with other manufacturing systems

9. Explain the importance of proper labeling for product compliance and consumer safety?

Proper labeling is essential for:

- Meeting regulatory requirements

- Providing accurate product information to consumers

- Ensuring product traceability

- Protecting consumers from potential hazards

10. How do you stay updated on the latest labeling technologies and industry best practices?

To stay updated on labeling technologies and best practices, I:

- Attend industry conferences and exhibitions

- Read trade publications and online resources

- Consult with equipment manufacturers and suppliers

- Seek training and certification opportunities

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Labeling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Labeling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Labeling Machine Operators are responsible for operating and maintaining labeling machines. They work in a variety of industries, including food and beverage, pharmaceutical, and manufacturing. Key job responsibilities include:

1. Operating Labeling Machines

Labeling Machine Operators set up, calibrate, and operate labeling machines. They ensure that the machines are running smoothly and that labels are being applied correctly to products. They may also be responsible for troubleshooting and repairing minor machine problems.

2. Monitoring Production

Labeling Machine Operators monitor production to ensure that products are being labeled correctly and efficiently. They may also be responsible for collecting data on production output and quality.

3. Maintaining Labeling Machines

Labeling Machine Operators are responsible for maintaining labeling machines. They may perform regular cleaning and lubrication, as well as more complex repairs. They may also be responsible for ordering and installing replacement parts.

4. Ensuring Safety

Labeling Machine Operators are responsible for ensuring safety in the workplace. They may be responsible for following safety procedures, such as wearing appropriate clothing and equipment, and for reporting any unsafe conditions.

Interview Preparation Tips

To prepare for an interview for a Labeling Machine Operator position, candidates should:

1. Research the company and the position

Candidates should research the company they are applying to and the position they are applying for. This will help them to understand the company’s culture and values, as well as the specific requirements of the position.

2. Practice answering common interview questions

Candidates should practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” They should also be prepared to discuss their experience and qualifications.

3. Be prepared to talk about their safety knowledge

Candidates should be prepared to talk about their safety knowledge and experience. This may include discussing their knowledge of safety procedures and their experience working in a safe environment.

4. Be prepared to demonstrate their mechanical skills

Candidates should be prepared to demonstrate their mechanical skills. This may include demonstrating their ability to perform basic repairs or to troubleshoot and resolve mechanical problems.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Labeling Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Labeling Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.