Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lace Paper Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

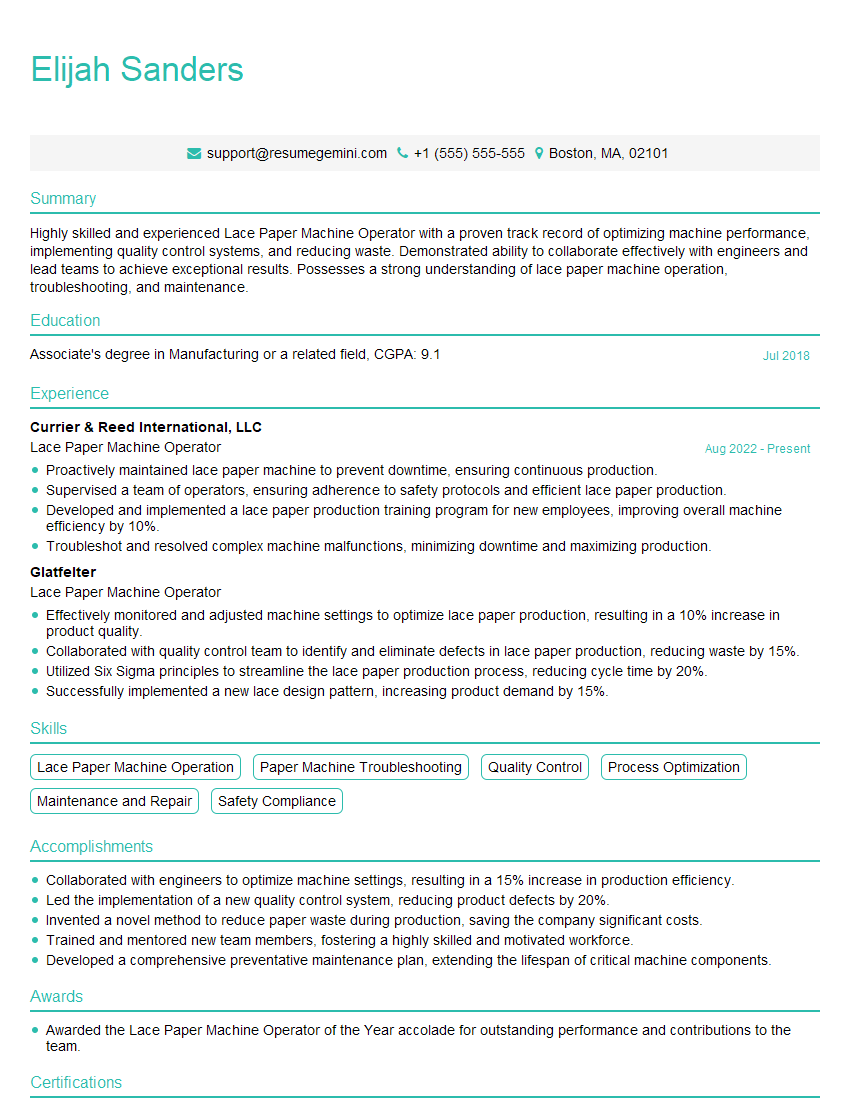

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lace Paper Machine Operator

1. Describe the key components of a lace paper machine and their respective functions

The key components of a lace paper machine and their respective functions are:

- Headbox: The headbox creates a uniform slurry of fibers and water.

- Wire: The wire is a moving screen that receives the slurry from the headbox and allows the water to drain away, forming a wet sheet of paper.

- Presses: The presses squeeze the water out of the wet sheet of paper, reducing its moisture content.

- Dryers: The dryers evaporate the remaining water from the paper, making it dry and strong.

- Winder: The winder rolls the finished paper onto a reel.

2. What are the different types of lace patterns that can be produced on a lace paper machine?

- Geometrical patterns: These patterns are created by repeating geometric shapes, such as squares, triangles, and circles.

- Floral patterns: These patterns are created by printing floral designs onto the paper.

- Animal patterns: These patterns are created by printing images of animals onto the paper.

- Custom patterns: These patterns are created by designing a specific pattern and programming it into the machine.

3. Explain the process of setting up a lace paper machine for a new production run

The process of setting up a lace paper machine for a new production run involves the following steps:

- Preparing the machine: This involves cleaning the machine and making sure that all of the components are in good working order.

- Loading the paper: The paper is loaded onto the machine and the machine is adjusted to the correct settings for the desired lace pattern.

- Starting the machine: The machine is started and the slurry is fed into the headbox.

- Monitoring the machine: The machine is monitored to ensure that it is running smoothly and that the paper is being produced to the correct specifications.

4. What are the common problems that can occur during lace paper production and how can they be resolved?

Some common problems that can occur during lace paper production include:

- Paper breaks: Paper breaks can be caused by a variety of factors, such as incorrect machine settings, poor quality paper, or foreign objects in the paper.

- Uneven lace patterns: Uneven lace patterns can be caused by incorrect machine settings or worn-out machine components.

- Poor paper quality: Poor paper quality can be caused by a variety of factors, such as incorrect raw materials, poor machine settings, or contamination.

These problems can be resolved by:

- Adjusting machine settings

- Replacing worn-out machine components

- Using higher quality paper

- Cleaning the machine

- Training operators

5. How would you troubleshoot a situation where the lace paper machine is not producing paper to the correct specifications?

If the lace paper machine is not producing paper to the correct specifications, I would troubleshoot the problem by:

- Checking the machine settings: I would check the machine settings to ensure that they are correct for the desired lace pattern and paper quality.

- Inspecting the machine components: I would inspect the machine components to identify any worn-out or damaged components that could be causing the problem.

- Testing the paper: I would test the paper to determine if it meets the desired specifications.

- Making adjustments: I would make adjustments to the machine settings or components as necessary to resolve the problem.

6. What are the safety procedures that must be followed when operating a lace paper machine?

The safety procedures that must be followed when operating a lace paper machine include:

- Wearing appropriate safety gear: This includes safety glasses, gloves, and a hard hat.

- Keeping the machine area clean and free of debris: This helps to prevent accidents and injuries.

- Never operating the machine when it is not in good working order: This helps to prevent accidents and injuries.

- Following all lockout/tagout procedures: This helps to prevent accidents and injuries.

- Being aware of the location of the emergency stop button: This helps to prevent accidents and injuries in the event of an emergency.

7. What are the maintenance procedures that must be followed to keep a lace paper machine running smoothly?

The maintenance procedures that must be followed to keep a lace paper machine running smoothly include:

- Regularly cleaning the machine: This helps to prevent the accumulation of debris and dirt, which can lead to problems.

- Inspecting the machine components: This helps to identify any worn-out or damaged components that need to be replaced.

- Lubricating the machine components: This helps to reduce friction and wear and tear.

- Following all manufacturer’s recommendations for maintenance: This helps to ensure that the machine is maintained properly.

8. How would you train a new operator on how to operate a lace paper machine?

I would train a new operator on how to operate a lace paper machine by:

- Explaining the different components of the machine and their functions

- Demonstrating how to operate the machine

- Guiding the operator as they practice operating the machine

- Providing the operator with a written training manual

- Answering the operator’s questions

9. What is your experience with working with different types of lace paper machines?

I have experience working with a variety of lace paper machines, including:

- [Machine Type 1]

- [Machine Type 2]

- [Machine Type 3]

I am familiar with the different features and capabilities of these machines and I am able to operate them safely and efficiently.

10. How do you stay up-to-date on the latest developments in lace paper machine technology?

I stay up-to-date on the latest developments in lace paper machine technology by:

- Reading trade publications

- Attending industry conferences

- Talking to other lace paper machine operators

- Taking online courses

- Visiting the websites of lace paper machine manufacturers

This helps me to learn about new technologies and techniques that can improve my productivity and efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lace Paper Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lace Paper Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lace Paper Machine Operators play a crucial role in the production of lace paper, a delicate and ornamental material used in packaging, wrapping, and decorative purposes. Their primary responsibilities involve operating and monitoring lace paper machines to ensure efficient and high-quality production.

1. Machine Operation and Maintenance

Lace Paper Machine Operators are responsible for the overall operation and maintenance of lace paper machines. This includes:

- Setting up, calibrating, and adjusting machines according to production specifications.

- Monitoring machine performance, identifying malfunctions, and performing necessary repairs and adjustments.

- Ensuring proper lubrication and maintenance of machines to prevent breakdowns and optimize performance.

2. Material Handling and Preparation

Operators handle and prepare raw materials used in lace paper production:

- Loading machines with pulp or paper stock.

- Adjusting material properties, such as consistency and viscosity, to meet production requirements.

- Maintaining the flow of materials throughout the production process.

3. Quality Control and Inspection

Lace Paper Machine Operators are responsible for ensuring the quality of lace paper produced:

- Conducting regular inspections of lace paper to assess quality parameters such as thickness, porosity, and pattern clarity.

- Identifying and troubleshooting defects.

- Making adjustments to machines or production processes to improve quality.

4. Safety and Hygiene

Lace Paper Machine Operators adhere to safety and hygiene regulations:

- Maintaining a clean and safe work environment.

- Wearing appropriate protective gear, such as gloves and masks.

- Following established safety protocols to prevent accidents and injuries.

Interview Tips

Preparing for an interview for a Lace Paper Machine Operator position requires a combination of technical knowledge and soft skills. Here are some tips to help candidates ace their interview.

1. Research the Company and Industry

Demonstrate your interest in the company and the lace paper industry by researching their website, news articles, and industry publications. This will provide context for your answers and show the interviewer that you are genuinely interested in the position.

2. Highlight Relevant Experience and Skills

Emphasize your experience operating lace paper machines or similar equipment. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact. Highlight your skills in material handling, quality control, and troubleshooting.

3. Show Enthusiasm and Motivation

Convey your passion for working in the lace paper industry and your desire to contribute to the company’s success. Express your eagerness to learn, grow, and take on new challenges.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions about the company’s production process, quality standards, and opportunities for career advancement.

Next Step:

Now that you’re armed with the knowledge of Lace Paper Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lace Paper Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini