Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lace Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

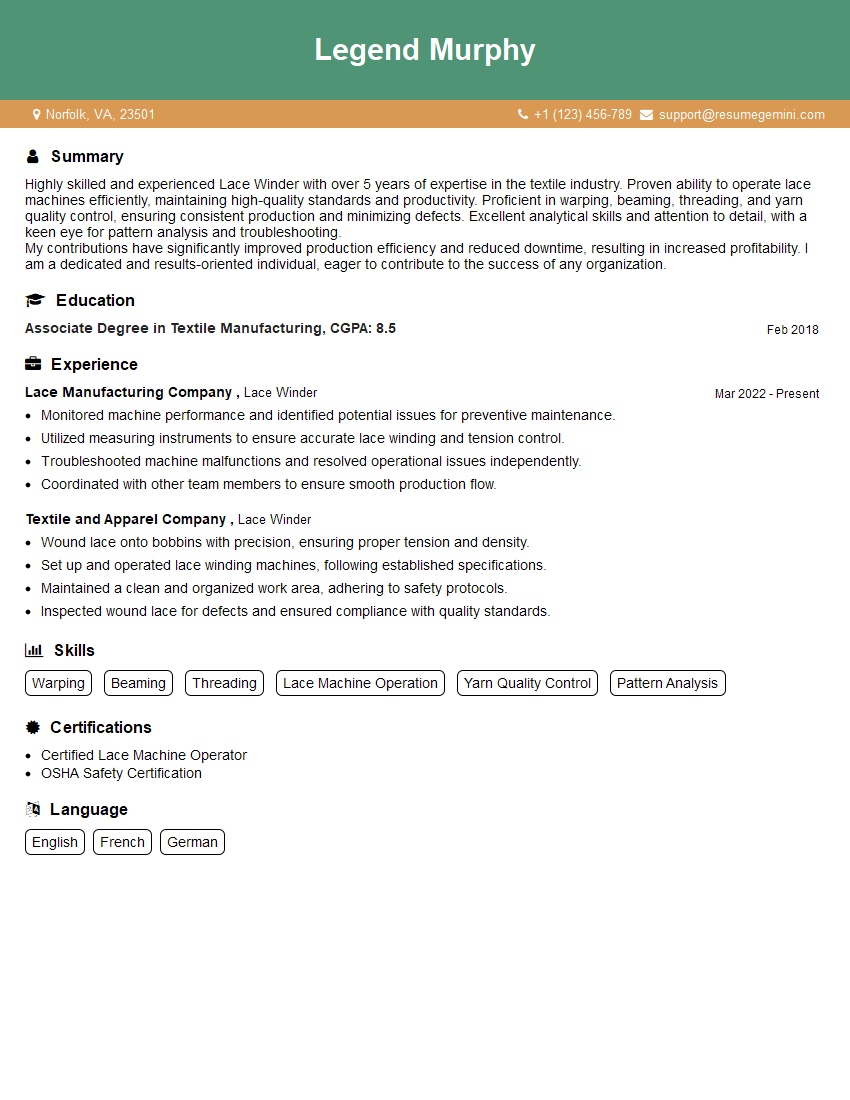

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lace Winder

1. Explain the process of lace winding in detail.

Here is a detailed explanation of the lace winding process:

- The first step is to prepare the yarn. This involves winding the yarn onto a bobbin or spool.

- The bobbin is then placed on the winding machine. The machine will have a number of spindles, each of which will hold a bobbin.

- The machine will then start to wind the yarn onto the lace. The lace is a thin, delicate fabric that is made from a variety of materials, such as cotton, silk, or nylon.

- The winding process is controlled by a computer program. The program will tell the machine how many times to wrap the yarn around the lace.

- Once the winding process is complete, the lace is removed from the machine and inspected. It is then ready to be used in a variety of applications, such as clothing, curtains, or upholstery.

2. What are the different types of lace winding machines and their uses?

There are a variety of lace winding machines available, each with its own specific uses. Some of the most common types of lace winding machines include:

Cylindrical lace winding machines

- These machines are used to wind lace onto a cylindrical bobbin.

- They are typically used for winding lace that will be used in clothing or curtains.

Flat lace winding machines

- These machines are used to wind lace onto a flat bobbin.

- They are typically used for winding lace that will be used in upholstery or other decorative applications.

Shuttle lace winding machines

- These machines use a shuttle to wind lace onto a bobbin.

- They are typically used for winding lace that is very delicate or intricate.

3. What are the key factors to consider when selecting a lace winding machine?

When selecting a lace winding machine, there are a number of key factors to consider, including:

- The type of lace that will be wound

- The desired production speed

- The accuracy of the winding

- The ease of operation

- The cost of the machine

4. What are the common problems that can occur during lace winding and how can they be resolved?

There are a number of common problems that can occur during lace winding, including:

- Yarn breakage

- Lace breakage

- Uneven winding

- Machine malfunction

These problems can be resolved by taking the following steps:

- Inspecting the yarn and lace for any defects

- Adjusting the machine settings

- Cleaning and lubricating the machine

- Calling a qualified technician

5. What are the latest trends in lace winding technology?

The latest trends in lace winding technology include:

- The development of new lace winding machines that are faster, more accurate, and easier to operate

- The use of new materials in lace winding, such as synthetic fibers and metallic yarns

- The development of new lace winding techniques, such as 3D lace winding

6. What are the safety precautions that should be taken when operating a lace winding machine?

When operating a lace winding machine, it is important to take the following safety precautions:

- Wear appropriate safety gear, such as gloves and safety glasses

- Keep the machine clean and free of debris

- Do not operate the machine if it is malfunctioning

- Follow all of the manufacturer’s instructions

7. What are the maintenance procedures for a lace winding machine?

The maintenance procedures for a lace winding machine include:

- Cleaning and lubricating the machine regularly

- Inspecting the machine for any signs of wear or damage

- Calibrating the machine regularly

- Following all of the manufacturer’s instructions

8. What are the troubleshooting procedures for a lace winding machine?

The troubleshooting procedures for a lace winding machine include:

- Checking the machine for any obvious signs of damage or wear

- Inspecting the yarn and lace for any defects

- Adjusting the machine settings

- Cleaning and lubricating the machine

- Calling a qualified technician

9. What are the quality control procedures for lace winding?

The quality control procedures for lace winding include:

- Inspecting the yarn and lace for any defects

- Checking the accuracy of the winding

- Testing the lace for strength and durability

- Following all of the manufacturer’s instructions

10. What are the different types of lace that can be wound on a lace winding machine?

The different types of lace that can be wound on a lace winding machine include:

- Bobbin lace

- Needle lace

- Tatting

- Crochet lace

- Knitted lace

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lace Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lace Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lace Winders perform intricate tasks involving the winding and handling of lace, a delicate material used in various industries such as fashion, textiles, and decorative arts.

1. Lace Winding

This is the core responsibility of Lace Winders, and it involves skillfully winding lace onto bobbins or spools. They must ensure that the lace is wound evenly, with the edges aligned and without any tangles or creases.

2. Bobbin Preparation

Before lace winding, Lace Winders are responsible for preparing the bobbins by attaching lace ends to them securely. They must ensure that the bobbins are clean, properly sized, and ready for winding.

3. Lace Inspection

Lace Winders perform thorough inspections of the lace they handle. They check for any defects, such as breaks, snags, or discoloration, to maintain the quality and integrity of the lace.

4. Equipment Maintenance

Lace Winders are often responsible for maintaining the winding machines they use. They perform regular cleaning, lubrication, and minor repairs to ensure the equipment is in good working order.

Interview Tips

To help candidates ace the interview for a Lace Winder position, here are some effective preparation tips:

1. Research the Company

Before the interview, candidates should thoroughly research the company they’re applying to. They should learn about the company’s history, mission, products, and work culture. This knowledge will help them understand the company’s needs and how their skills align with the role.

2. Practice Common Interview Questions

Candidates should anticipate and prepare answers to common interview questions, such as:

- Tell me about your experience in lace winding.

- How do you ensure the quality of your work?

- What are your strengths and weaknesses as a Lace Winder?

3. Highlight Relevant Skills and Experience

Candidates should emphasize their relevant skills and experience in their resume and during the interview. They should showcase their ability to wind lace expertly, inspect lace for defects, and maintain winding equipment. If they have experience in related fields, such as textile manufacturing or quality control, they should mention it.

4. Be Enthusiastic and Show Passion

Lace Winders play a vital role in the lace industry, and candidates should convey their enthusiasm and passion for this craft during the interview. They should demonstrate their appreciation for the delicate and intricate nature of lace and their dedication to maintaining its quality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lace Winder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.