Are you gearing up for a career in Lacquer Booth Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lacquer Booth Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

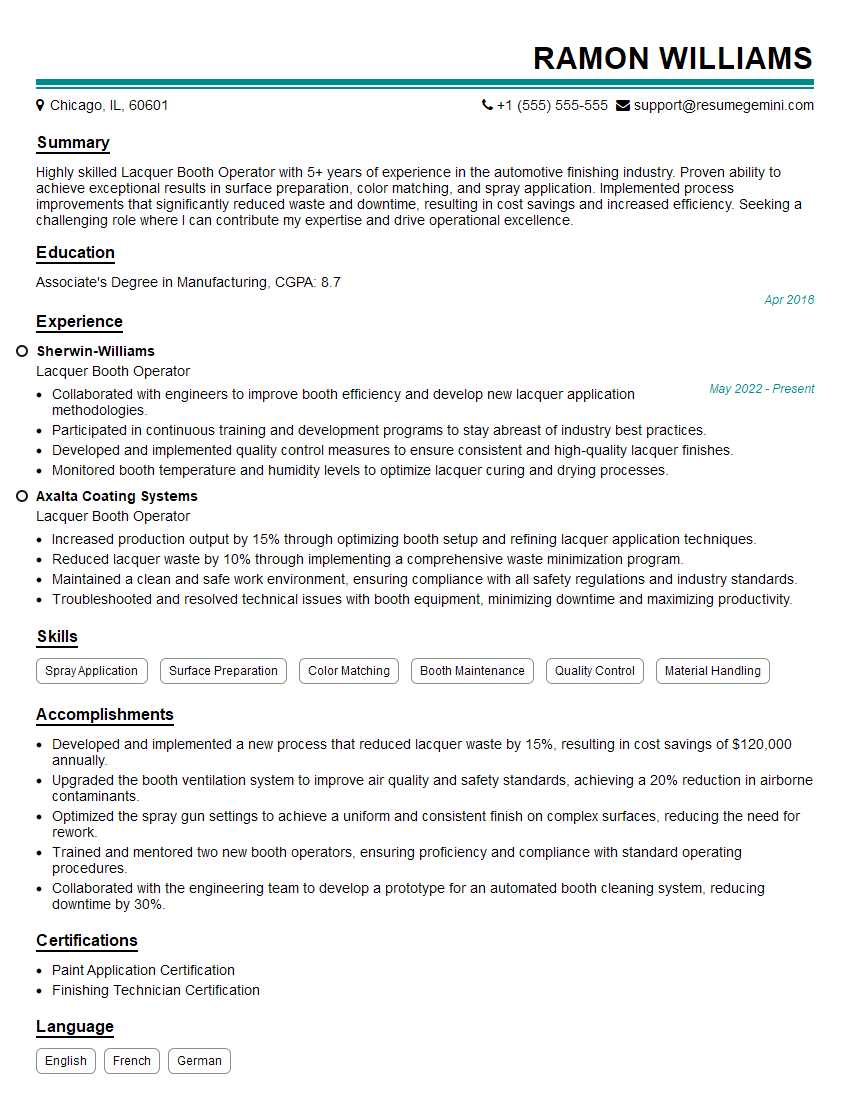

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lacquer Booth Operator

1. What is the purpose of a lacquer booth?

- The purpose of a lacquer booth is to provide a controlled environment for the application of lacquer.

- It helps to protect the applicator from the harmful fumes and dust generated during the process.

- It also helps to ensure a high-quality finish by maintaining a clean and dust-free environment.

2. What are the different types of lacquer booths?

Spray Booth

- Most common type of lacquer booth.

- Uses a spray gun to apply lacquer to the surface.

Dip Tank

- Consists of a tank filled with lacquer.

- Parts are dipped into the tank to apply lacquer.

Flow Coating

- Uses a curtain of lacquer to coat parts.

- Parts are passed through the curtain to apply lacquer.

3. What are the key factors to consider when selecting a lacquer booth?

- The size and shape of the parts to be coated.

- The type of lacquer being used.

- The desired production rate.

- The available space and budget.

4. What are the safety precautions that must be taken when working in a lacquer booth?

- Wear appropriate personal protective equipment (PPE), including a respirator, gloves, and eye protection.

- Ensure proper ventilation to prevent the accumulation of harmful fumes.

- Keep the booth clean and free of debris.

- Follow all manufacturer’s instructions for the safe operation of the booth.

5. How do you maintain a lacquer booth?

- Regularly clean the filters and exhaust system.

- Inspect the booth for any damage or wear and tear.

- Calibrate the equipment to ensure it is operating properly.

- Follow the manufacturer’s recommendations for maintenance and safety.

6. What are the common problems that can occur with lacquer booths?

- Clogged filters.

- Malfunctioning exhaust system.

- Improperly calibrated equipment.

- Damaged or worn parts.

7. How do you troubleshoot a lacquer booth?

- Check the filters and clean or replace them if necessary.

- Inspect the exhaust system for any blockages or leaks.

- Calibrate the equipment according to the manufacturer’s instructions.

- Inspect the booth for any damage or wear and tear and repair or replace as necessary.

8. What are the different types of lacquer?

- Nitrocellulose lacquer: Quick-drying, high-gloss finish.

- Acrylic lacquer: Durable, resistant to chemicals and UV radiation.

- Polyurethane lacquer: Excellent adhesion, high-build, and scratch resistance.

- Water-based lacquer: Environmentally friendly, low-VOC.

9. What are the factors that affect the quality of a lacquer finish?

- Surface preparation.

- Lacquer application technique.

- Lacquer quality.

- Booth conditions.

- Curing process.

10. How do you ensure the quality of a lacquer finish?

- Properly prepare the surface to be coated.

- Apply the lacquer according to the manufacturer’s instructions.

- Use high-quality lacquer.

- Maintain the booth in good condition.

- Follow the recommended curing process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lacquer Booth Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lacquer Booth Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lacquer Booth Operators play a crucial role in the finishing process of manufactured goods, utilizing specialized equipment and techniques to apply protective and decorative coatings. Their core responsibilities encompass:

1. Lacquer Application

Utilize spray guns or electrostatic applicators to apply lacquer coatings to various surfaces, ensuring uniform coverage and adherence to specifications.

- Select and adjust application equipment based on product characteristics and desired finish.

- Monitor coating thickness and viscosity to maintain quality standards.

2. Booth Operation and Maintenance

Operate and maintain lacquer booths, including ventilation systems, filters, and spray guns, to ensure a safe and efficient work environment.

- Conduct regular inspections and cleanings to prevent contamination and equipment malfunction.

- Troubleshoot and resolve operational issues, minimizing downtime.

3. Quality Control

Inspect coated surfaces for defects, such as runs, sags, or pinholes, and take corrective actions to maintain product quality.

- Utilize quality control instruments to measure coating thickness and other parameters.

- Document inspection results and maintain records for traceability.

4. Safety and Compliance

Adhere strictly to safety regulations and company procedures, handling hazardous materials responsibly and using proper protective equipment.

- Participate in safety training programs and follow established protocols.

- Ensure compliance with environmental regulations regarding emissions and waste disposal.

Interview Tips

To ace an interview for a Lacquer Booth Operator position, candidates should consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, operations, and industry trends. This demonstrates your interest and enthusiasm for the role.

- Visit the company website and read industry publications.

- Connect with current or former employees on LinkedIn for insights.

2. Highlight Relevant Skills and Experience

Emphasize your skills in lacquer application, booth operation and maintenance, quality control, and safety compliance. Provide specific examples of your experience and accomplishments.

- Quantify your results whenever possible, using metrics like production rates or quality improvement percentages.

- Showcase your knowledge of different coating materials and application techniques.

3. Prepare for Technical Questions

Anticipate questions about lacquer booth operation, coating defects, and quality control procedures. Practice explaining your understanding and experience in these areas.

- Review the job description carefully and identify specific technical terms and concepts.

- Use industry-standard terminology and demonstrate your understanding of industry best practices.

4. Demonstrate Safety Awareness and Compliance

Stress your commitment to safety and compliance with relevant regulations. Explain your knowledge of handling hazardous materials and using protective equipment.

- Highlight your experience with safety training programs and certifications.

- Discuss your understanding of environmental regulations and waste disposal practices.

5. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer about the position, the company, and the industry. This shows your engagement and interest in the opportunity.

- Ask about the company’s growth plans and future goals.

- Inquire about the training and development opportunities available for employees.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lacquer Booth Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.