Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lacquer Dipping Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

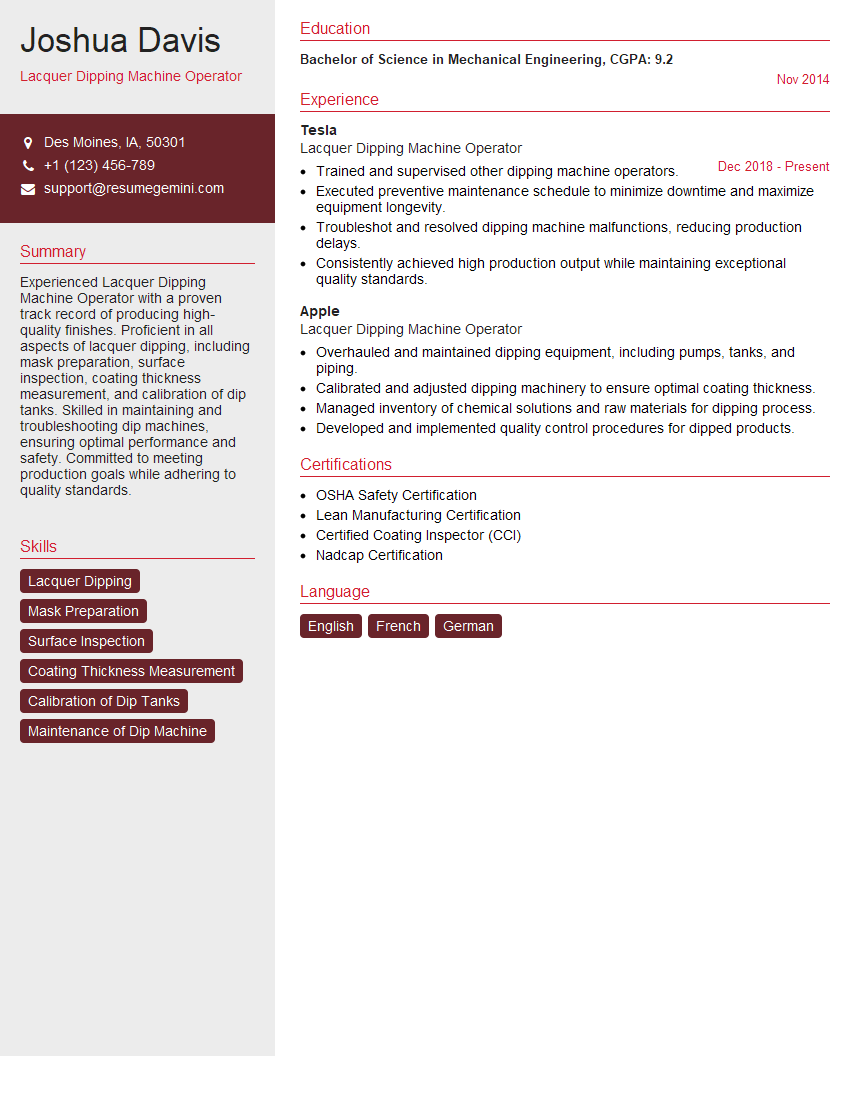

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lacquer Dipping Machine Operator

1. Describe the key steps involved in the lacquer dipping process.

- Prepare the parts by cleaning and degreasing them.

- Dip the parts into the lacquer bath at a controlled speed and depth.

- Withdraw the parts from the bath at a controlled speed.

- Allow the parts to drain and dry.

2. What are the different types of lacquer dipping machines?

Conveyorized

- Parts are hung on a conveyor and passed through a series of tanks containing different chemicals.

- Efficient for high-volume production.

Dip and drain

- Parts are dipped into a tank of lacquer and then drained.

- Suitable for small-volume production or parts with complex shapes.

Flow coating

- Lacquer is pumped over the parts, creating a smooth, even coating.

- Capable of handling large parts or complex shapes.

3. What are the main factors that affect the quality of the lacquer coating?

- Lacquer viscosity and temperature

- Part preparation and cleaning

- Dipping speed and depth

- Drying conditions

4. How do you troubleshoot common lacquer dipping problems?

- Bubbling or blistering: Check lacquer viscosity, air bubbles, or part cleanliness.

- Uneven coating: Adjust dipping speed, depth, or lacquer temperature.

- Cracking or peeling: Ensure proper part preparation and drying conditions.

5. What maintenance procedures are required for lacquer dipping machines?

- Regularly clean and inspect tanks, pumps, and filters.

- Calibrate dipping equipment and ensure proper operation.

- Follow manufacturer’s guidelines for maintenance and repair.

6. Describe your experience in monitoring and controlling lacquer dipping processes.

7. What safety precautions should be taken when operating a lacquer dipping machine?

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and respirator.

- Handle lacquer chemicals with care and follow proper disposal procedures.

- Ensure proper ventilation to minimize exposure to fumes.

8. How do you stay up-to-date on advancements in lacquer dipping technology?

- Attend industry conferences and workshops.

- Read trade publications and technical articles.

- Collaborate with equipment manufacturers and chemical suppliers.

9. Provide an example of a time when you successfully resolved a complex lacquer dipping issue.

- Describe the problem and the steps taken to identify the root cause.

- Explain the solution implemented and the positive impact it had.

10. What are your career goals and how does this position align with them?

- Express interest in contributing to the company’s success.

- Highlight how the position aligns with your skills and aspirations.

- Demonstrate a commitment to professional development.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lacquer Dipping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lacquer Dipping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Lacquer Dipping Machine Operator is responsible for the production of lacquered products. The job requires a high level of precision and attention to detail, as well as a strong understanding of the processes involved in dipping products into lacquer. Key responsibilities include:

1. Operating the lacquer dipping machine

This involves setting up the machine, loading the parts, and monitoring the dipping process. Lacquer Dipping Machine Operator must be able to adjust the machine settings to ensure that the parts are coated evenly and to the correct thickness and to ensure that the machine is running safely and efficiently.

- Make sure that the machine is calibrated and running smoothly.

- Adjust the settings of the machine to ensure that the parts are coated evenly and to the correct thickness.

- Monitor the dipping process to ensure that the parts are completely coated and that the lacquer is drying properly.

2. Preparing the parts for dipping

This involves cleaning the parts, masking off any areas that should not be coated, and applying a primer. Lacquer Dipping Machine Operator must be able to follow the instructions in the work order and to use the correct materials and equipment.

- Clean the parts to remove any dirt or debris.

- Mask off any areas of the parts that should not be coated.

- Apply a primer to the parts to help the lacquer adhere.

3. Inspecting the finished parts

Lacquer Dipping Machine Operator must be able to identify any defects in the finished parts and to correct them. This involves visually inspecting the parts and using a magnifying glass to check for any imperfections. If any defects are found, Lacquer Dipping Machine Operator must be able to sand them out or touch them up with lacquer.

- Visually inspect the finished parts to identify any defects.

- Use a magnifying glass to check for any imperfections.

- Sand out or touch up any defects with lacquer.

4. Maintaining the dipping machine

Lacquer Dipping Machine Operator must be able to perform basic maintenance on the dipping machine. This includes cleaning the machine, lubricating the moving parts, and replacing any worn or damaged parts. Lacquer Dipping Machine Operator must also be able to troubleshoot any problems that may occur with the machine.

- Clean the machine to remove any lacquer residue.

- Lubricate the moving parts of the machine.

- Replace any worn or damaged parts.

- Troubleshoot any problems that may occur with the machine.

Interview Tips

Here are some tips to help you prepare for your interview for a Lacquer Dipping Machine Operator position:

1. Research the company and the position

This will help you to understand the company’s culture and the specific requirements of the position. You can find information about the company on their website and in industry publications. You can also find information about the position by reading the job description and talking to people who work in the industry.

- Visit the company’s website to learn about their history, products, and services.

- Read industry publications to learn about the latest trends and technologies.

- Talk to people who work in the industry to get their insights on the position.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Prepare a brief introduction of yourself that highlights your skills and experience.

- Think about why you are interested in the position and what you can bring to the company.

- Practice answering these questions out loud so that you can become more comfortable with the delivery.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in the industry and your skills as a Lacquer Dipping Machine Operator. Be prepared to talk about your previous jobs and the specific tasks that you performed. You should also be prepared to discuss your skills in operating and maintaining a lacquer dipping machine.

- Describe your previous jobs and the specific tasks that you performed.

- Highlight your skills in operating and maintaining a lacquer dipping machine.

- Quantify your experience whenever possible, such as by stating the number of parts that you have coated or the amount of time that you have spent operating a machine.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic about the position and who is positive about their ability to do the job. Be sure to show your enthusiasm during the interview and to highlight your positive attitude.

- Smile and make eye contact with the interviewer.

- Speak confidently and clearly.

- Be positive and enthusiastic about the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lacquer Dipping Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!