Feeling lost in a sea of interview questions? Landed that dream interview for Lacquerer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lacquerer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

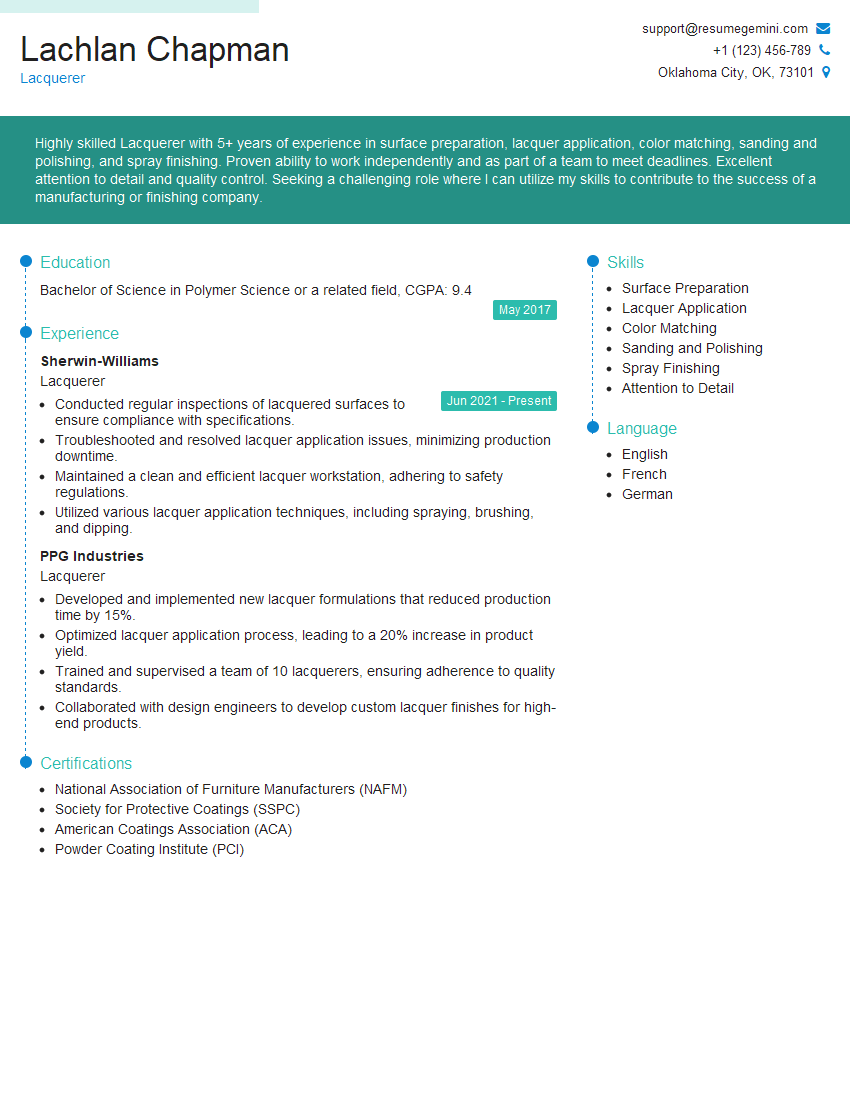

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lacquerer

1. What is lacquer, and what are its main components?

Lacquer is a natural resinous substance obtained from the sap of certain trees, primarily the lacquer tree (Toxicodendron vernicifluum). Its main components include urushiol, which is responsible for lacquer’s characteristic properties and potential allergenic effects; various other organic compounds, such as triterpenoids, phenols, and carbohydrates; and water.

2. Describe the traditional process of lacquerware production.

Urushi Application

- The sap is collected from the tree and strained to remove impurities.

- Raw urushi is then applied to the surface of the object to be lacquered, typically in multiple thin layers.

Drying and Polishing

- Each layer of urushi is allowed to dry in a humid environment, which promotes the cross-linking of urushiol and results in a hard, durable finish.

- The surface is then polished to achieve a smooth, glossy appearance.

3. Explain the differences between raw and refined lacquer.

Raw lacquer is obtained directly from the tree and contains impurities, such as protein and water. Refined lacquer has undergone additional processing to remove these impurities, resulting in a more stable and less allergenic product. Refined lacquer is typically used for high-quality lacquerware, while raw lacquer may be used for less expensive or traditional items.

4. What are the factors that influence the quality of lacquerware?

The quality of lacquerware is influenced by various factors, including:

- The type and quality of urushi used.

- The number of layers of urushi applied.

- The drying and curing conditions.

- The skill and experience of the lacquerer.

5. What are the potential hazards associated with lacquer and how can they be mitigated?

Lacquer contains urushiol, which can cause skin irritation, allergic reactions, and in severe cases, anaphylaxis. To mitigate these hazards, it is important to:

- Wear protective gear, such as gloves and masks, when handling lacquer.

- Work in a well-ventilated area.

- Avoid contact with the eyes and skin.

- Use raw lacquer only in well-ventilated areas.

- Seek medical attention immediately if an allergic reaction occurs.

6. Describe the process of repairing lacquerware.

Repairing lacquerware involves several steps:

- Cleaning the damaged area to remove any dirt or debris.

- Applying a small amount of raw lacquer to the damaged area.

- Allowing the lacquer to dry and cure.

- Polishing the repaired area to match the surrounding finish.

7. How can lacquer be used in contemporary applications?

In addition to traditional lacquerware, lacquer can be used in various contemporary applications, including:

- As a protective coating for wood, metal, and other materials.

- In the production of jewelry, musical instruments, and other decorative objects.

- As a component of composite materials.

- In the development of new industrial products and technologies.

8. What are the emerging trends in lacquerware production?

Emerging trends in lacquerware production include:

- The use of sustainable and environmentally friendly materials.

- The incorporation of new techniques and technologies, such as 3D printing and laser engraving.

- The exploration of new design concepts and aesthetics.

- The growing demand for custom and personalized lacquerware.

9. What is your approach to quality control in lacquerware production?

In order to ensure the highest quality, I follow a rigorous approach to quality control, which includes:

- Selecting the finest quality raw materials.

- Implementing strict production standards and processes.

- Thoroughly inspecting each piece at various stages of production.

- Seeking feedback from clients to continuously improve my techniques and products.

10. What is your philosophy on customer service?

I believe that excellent customer service is essential in any industry, and I am committed to providing my clients with the highest level of support and satisfaction. I am always available to answer any questions, provide advice, and assist with any issues that may arise. I strive to build long-lasting relationships with my clients, based on trust and mutual respect.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lacquerer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lacquerer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lacquerers apply lacquer and other finishes to a variety of surfaces, including wood, metal, plastic, and glass. They work in a variety of settings, including furniture factories, automotive plants, and art studios. Lacquerers must be able to follow instructions carefully and work independently.

1. Surface Preparation

Lacquerers begin by preparing the surface to be finished. This may involve sanding, cleaning, or priming the surface. They must be able to assess the condition of the surface and determine the best way to prepare it for finishing.

- Sand, clean, and prime surfaces to prepare for finishing

- Inspect surfaces for defects and make necessary repairs

- Apply masking tape or other protective coverings to protect areas that should not be finished

2. Lacquer Application

Once the surface is prepared, the lacquerer applies the lacquer. This can be done using a variety of methods, including spraying, dipping, or brushing. Lacquerers must be able to control the thickness and evenness of the lacquer application.

- Apply lacquer to surfaces using a variety of methods, such as spraying, dipping, or brushing

- Control the thickness and evenness of the lacquer application

- Inspect the finished surface for defects and make necessary corrections

3. Lacquer Curing

After the lacquer is applied, it must be cured. This involves allowing the lacquer to dry and harden. Lacquerers must be able to monitor the curing process and ensure that the lacquer is properly cured.

- Monitor the lacquer curing process and ensure that the lacquer is properly cured

- Make adjustments to the curing process as needed

- Inspect the finished surface for defects and make necessary repairs

4. Clean-up

Once the lacquer is cured, the lacquerer must clean up the work area. This may involve removing masking tape or other protective coverings, cleaning brushes and other equipment, and disposing of waste materials.

- Remove masking tape or other protective coverings

- Clean brushes and other equipment

- Dispose of waste materials

Interview Tips

Preparing for an interview can be daunting, but there are some things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a lacquerer position.

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website and social media pages

- Read industry publications and news articles

- Talk to people who work at the company, if possible

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral interview questions

- Be prepared to talk about your skills and experience

- Highlight your transferable skills, even if they are not directly related to lacquering

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the workplace.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing strong perfumes or colognes

4. Be Punctual

Punctuality shows that you respect the interviewer’s time. Plan your route to the interview in advance and allow yourself plenty of time to get there. If you are running late, call or email the interviewer to let them know.

- Plan your route to the interview in advance

- Allow yourself plenty of time to get there

- If you are running late, call or email the interviewer to let them know

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lacquerer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.