Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ladle Filler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ladle Filler so you can tailor your answers to impress potential employers.

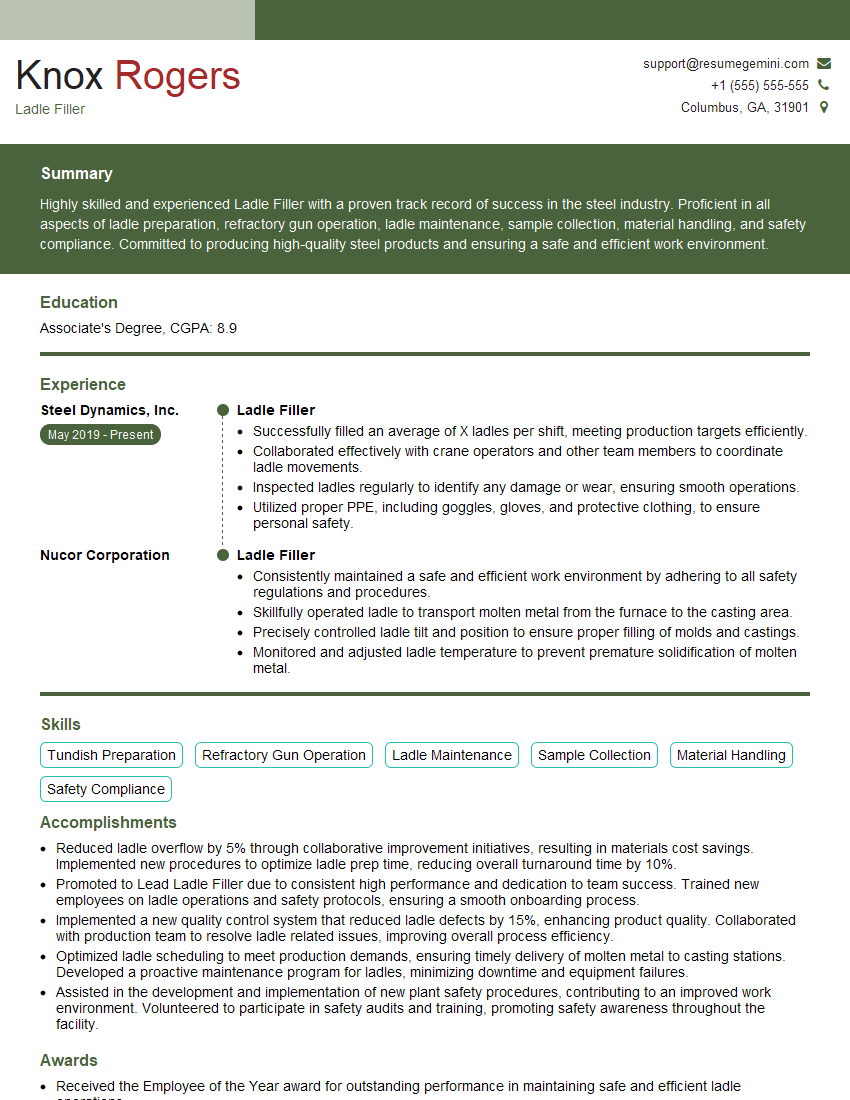

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ladle Filler

1. What are the key responsibilities of a Ladle Filler?

- Filling ladles with molten metal from furnaces or other sources

- Operating equipment to control the flow of molten metal

- Monitoring the filling process and ensuring that the ladle is filled to the correct level

- Inspecting the ladle for any defects or damage

- Maintaining and cleaning equipment

2. What are the safety precautions that must be taken when working with molten metal?

- Wear appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, gloves, and a fire-resistant suit

- Stay clear of the molten metal and avoid contact with it

- Do not operate equipment if you are not properly trained

- Be aware of the potential hazards of molten metal, such as burns, explosions, and fires

- Follow all safety procedures and guidelines

3. What are the different types of ladles used in metalworking?

- Top pour ladles

- Bottom pour ladles

- Tilt pour ladles

- Crane ladles

- Hand ladles

4. What are the advantages and disadvantages of using a top pour ladle?

Advantages:

- Easy to fill

- Can be used for a variety of metals

- Relatively inexpensive

Disadvantages:

- Can be difficult to control the flow of metal

- Can spill metal if not properly handled

- Not suitable for use with certain metals

5. What are the advantages and disadvantages of using a bottom pour ladle?

Advantages:

- Provides a more controlled flow of metal

- Less likely to spill metal

- Can be used with a variety of metals

Disadvantages:

- More difficult to fill

- More expensive than top pour ladles

- Not suitable for use with certain metals

6. What are the advantages and disadvantages of using a tilt pour ladle?

Advantages:

- Easy to control the flow of metal

- Can be used for a variety of metals

- Relatively inexpensive

Disadvantages:

- Can be difficult to fill

- Can spill metal if not properly handled

- Not suitable for use with certain metals

7. What are the advantages and disadvantages of using a crane ladle?

Advantages:

- Can be used to transport large volumes of metal

- Can be used for a variety of metals

- Relatively easy to use

Disadvantages:

- Can be expensive to purchase and operate

- Requires a crane to operate

- Not suitable for use in confined spaces

8. What are the advantages and disadvantages of using a hand ladle?

Advantages:

- Inexpensive

- Easy to use

- Portable

Disadvantages:

- Can only be used to transport small volumes of metal

- Not suitable for use with certain metals

- Can be difficult to control the flow of metal

9. What are the different types of furnaces used in metalworking?

- Arc furnaces

- Induction furnaces

- Resistance furnaces

- Crucible furnaces

- Reverbatory furnaces

10. What are the advantages and disadvantages of using an arc furnace?

Advantages:

- Can melt a variety of metals

- Relatively fast melting times

- Can be used to produce high-quality metal

Disadvantages:

- Can be expensive to operate

- Can produce a lot of noise and pollution

- Requires skilled operators

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ladle Filler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ladle Filler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Ladle Filler is an essential member of a foundry team, responsible for preparing and filling ladles with molten metal for casting operations. Their primary duties include:

1. Ladle Preparation

Preparing ladles for use, ensuring they are clean, dry, and preheated to the required temperature.

- Inspecting ladles for damage or defects.

- Applying coatings or linings to ladles to prevent contamination.

2. Charge Weighing and Calculation

Weighing and calculating the required amount of molten metal for each cast.

- Using scales and measuring equipment to determine accurate weights.

- Adjusting charges as needed to meet specifications.

3. Metal Transfer

Transferring molten metal from a furnace or other source into the prepared ladle.

- Using cranes or other equipment to move molten metal safely.

- Controlling the flow of metal to prevent spills or accidents.

4. Ladle Inspection and Maintenance

Inspecting ladles after use and performing basic maintenance to ensure they are in good condition.

- Identifying and reporting any damage or wear.

- Cleaning and repairing ladles as needed.

5. Safety and Compliance

Adhering to safety regulations and procedures while working with molten metal.

- Wearing appropriate personal protective equipment (PPE).

- Following established safety protocols to prevent accidents.

Interview Tips

To ace an interview for a Ladle Filler position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s products, operations, and specific requirements for the Ladle Filler role.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Emphasize Safety and Attention to Detail

Highlight your commitment to safety and your meticulous attention to detail, as these qualities are crucial for Ladle Fillers.

- Describe how you have ensured safety in previous roles.

- Provide examples of your ability to follow precise instructions.

3. Showcase Physical Abilities

Ladle Fillers must be physically capable of handling heavy materials and working in a demanding environment.

- Quantify your physical capabilities, such as lifting capacity.

- Describe your experiences working in physically challenging conditions.

4. Prepare for Technical Questions

Be ready to answer questions about your knowledge of metal casting, ladle preparation, and safety procedures.

- Review common casting techniques and ladle handling practices.

- Familiarize yourself with industry standards and regulations.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ladle Filler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ladle Filler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.