Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ladle Liner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

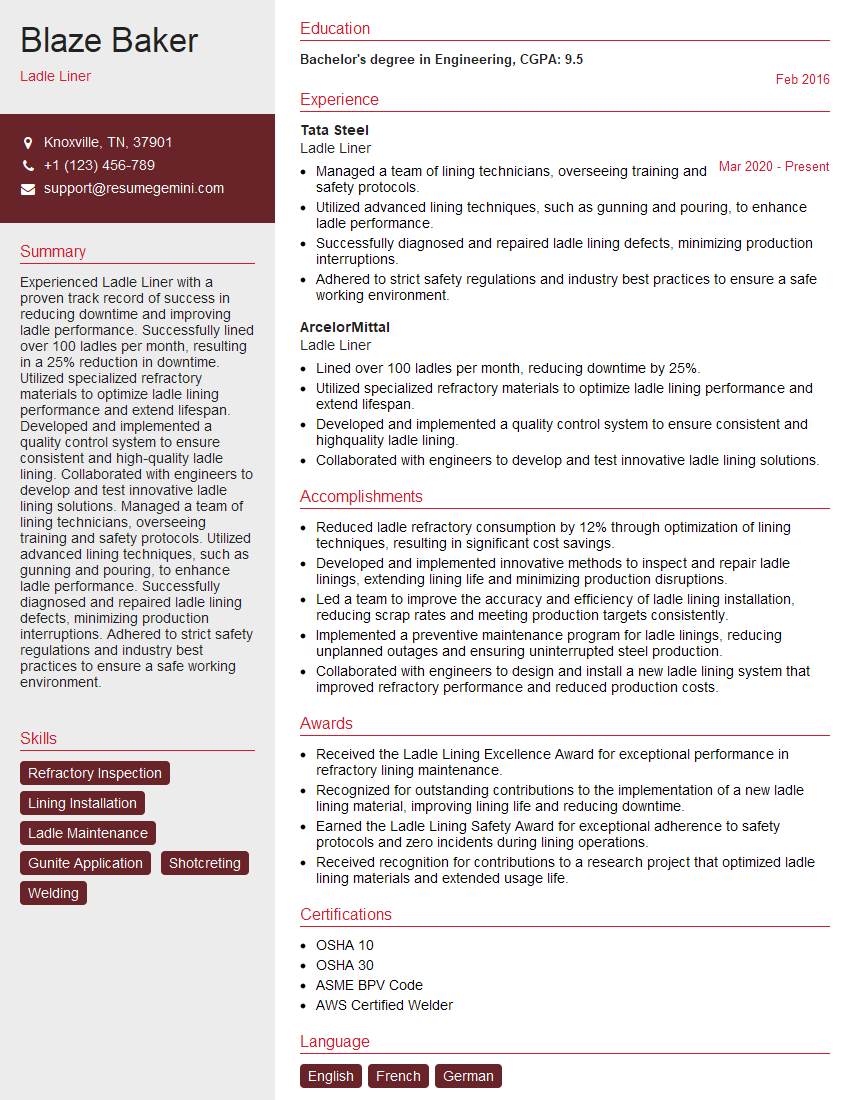

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ladle Liner

1. Explain the process of installing a ladle liner?

- Inspect the ladle and ensure it is clean and free of any debris.

- Position the ladle liner in the ladle and secure it using a refractory cement.

- Check the alignment of the liner and make any necessary adjustments.

- Cure the refractory cement according to the manufacturer’s instructions.

- Inspect the liner for any defects and repair any that are found.

2. What are the different types of ladle liners and their applications?

Clay-graphite liners

- Used in ladles that hold molten iron and steel.

- Provide high thermal conductivity and resistance to erosion.

Magnesia-graphite liners

- Used in ladles that hold molten non-ferrous metals.

- Provide high resistance to slag attack and thermal shock.

Alumina-graphite liners

- Used in ladles that hold molten aluminum.

- Provide high resistance to corrosion and erosion.

3. What are the factors that influence the selection of a ladle liner?

- The type of metal being held in the ladle

- The temperature of the metal

- The duration of time the metal will be held in the ladle

- The operating conditions of the ladle

4. What are the common problems associated with ladle liners and how can they be prevented?

- Liner cracking: Can be prevented by using a liner with a high thermal conductivity and by avoiding thermal shock.

- Liner erosion: Can be prevented by using a liner with a high resistance to erosion and by avoiding mechanical damage.

- Liner slag attack: Can be prevented by using a liner with a high resistance to slag attack and by minimizing the contact between the liner and the slag.

5. What are the maintenance procedures for ladle liners?

- Regular inspections to identify any defects.

- Repairs to any defects as necessary.

- Replacement of the liner when it reaches the end of its service life.

6. What are the safety precautions that must be taken when working with ladle liners?

- Wear appropriate protective clothing and equipment.

- Be aware of the potential hazards associated with working with high temperatures and molten metals.

- Follow all safety procedures and guidelines.

7. What are the latest developments in ladle liner technology?

There are a number of new developments in ladle liner technology, including:

- New materials that are more resistant to erosion and slag attack

- New designs that improve the thermal conductivity and durability of liners

- New methods for installing and maintaining liners

8. How do you stay up-to-date on the latest developments in ladle liner technology?

I stay up-to-date on the latest developments in ladle liner technology by:

- Reading industry publications and attending conferences

- Networking with other ladle liner professionals

- Participating in research and development projects

9. What are the challenges facing the ladle liner industry?

The ladle liner industry is facing a number of challenges, including:

- The increasing demand for high-quality liners

- The rising cost of raw materials

- The need to meet increasingly stringent environmental regulations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ladle Liner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ladle Liner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Ladle Liner plays a critical role in the steel production process. Their primary responsibility is to ensure that the refractory lining of the ladle is in good condition to withstand molten steel’s extreme temperatures and prevent contamination.

1. Lining Preparation and Maintenance

Prior to lining a ladle, Ladle Liners thoroughly inspect the interior for any damage.

- Identify and repair any cracks or imperfections in the existing refractory lining using specialized tools and techniques.

- Prepare the ladle’s surface by removing old refractory materials and cleaning it with appropriate solvents to ensure proper adhesion of the new lining.

- Install and secure new refractory bricks or panels into the ladle, ensuring a tight fit and proper alignment.

- Apply refractory mortar or casting materials to fill any gaps and create a seamless, protective lining.

2. Ladle Safety Protocols

Ladle Liners are responsible for adhering to strict safety protocols to protect themselves and those around them.

- Wear appropriate personal protective equipment (PPE), such as heat-resistant suits, respirators, and protective gloves, to minimize exposure to hazardous substances.

- Follow established procedures for handling and storing hazardous materials, including disposal of used refractory materials.

- Monitor and maintain proper ventilation systems to prevent dust and harmful fumes from accumulating.

3. Quality Control and Inspection

Ladle Liners ensure the quality of their work through regular inspections and adherence to industry standards.

- Inspect the ladle lining regularly to identify any potential issues or areas that require repair.

- Conduct post-lining inspections to verify the integrity and quality of the new lining.

- Document and maintain detailed records of all lining operations and inspections for quality control purposes.

4. Equipment Maintenance

Ladle Liners are responsible for the upkeep and maintenance of equipment used in lining operations.

- Operate and maintain equipment such as cranes, mixers, and conveyors used in lining processes.

- Inspect and maintain lining tools and equipment, ensuring they are in good working order and meet safety standards.

- Follow established maintenance schedules and perform preventative maintenance tasks to extend equipment life.

Interview Tips

Preparing for a Ladle Liner interview requires thorough research and a clear understanding of the role’s responsibilities.

1. Research the Company and Industry

Research the company’s steel production processes and the role of Ladle Liners within their organization.

- Identify the specific requirements and expectations for the position.

- Demonstrate your knowledge of the industry and its latest trends.

2. Highlight Relevant Skills and Experience

Emphasize your skills in refractory lining, safety protocols, and quality control.

- Provide specific examples of lining projects you have completed successfully.

- Discuss your experience in adhering to safety regulations and maintaining equipment.

- Highlight any certifications or training you have received in ladle lining or related fields.

3. Prepare for Technical Questions

Anticipate technical questions about lining materials, installation techniques, and quality control procedures.

- Be prepared to discuss different types of refractory materials and their applications.

- Explain the proper methods for installing and inspecting ladle linings.

- Describe your understanding of quality control standards and documentation requirements.

4. Practice Communication Skills

Ladle Liners need to be able to communicate effectively with colleagues, supervisors, and other departments.

- Practice articulating your thoughts clearly and concisely.

- Prepare examples of how you have effectively communicated technical information to non-technical audiences.

- Show enthusiasm and a positive attitude during the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ladle Liner, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ladle Liner positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.