Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ladle Puller interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ladle Puller so you can tailor your answers to impress potential employers.

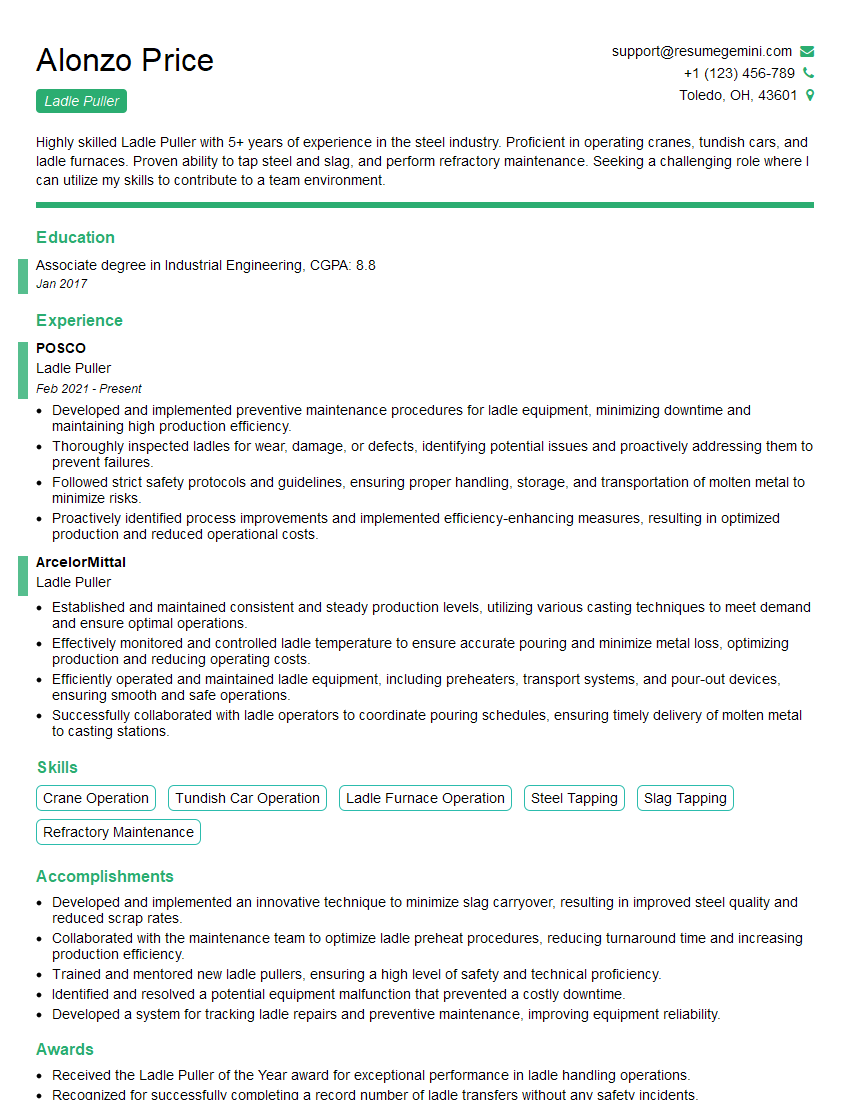

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ladle Puller

1. What are the safety precautions you take when operating a ladle puller?

As a Ladle Puller, safety is my top priority. I always wear the appropriate protective gear, including a hard hat, safety glasses, gloves, and steel-toed boots. I also make sure that the ladle puller is in good working order before each use, and I never operate the equipment under the influence of drugs or alcohol.

2. How do you ensure that the ladle is correctly attached to the puller?

Double-Checking the Attachment

- Physically inspect the connection between the ladle and the puller to ensure it is secure.

- Verify the alignment of the ladle and the puller to prevent any tilting or slipping during operation.

Using Proper Equipment

- Employ the appropriate hooks, clamps, or other attachments designed specifically for handling ladles.

- Ensure that the equipment is in good condition and meets the weight capacity requirements for the ladle.

3. What steps do you take to prevent spills when pulling a ladle?

To prevent spills when pulling a ladle, I take the following steps:

- Check the ladle for any cracks or damage before pulling it.

- Make sure that the ladle is properly attached to the puller.

- Pull the ladle slowly and carefully to avoid jarring it.

- Keep the ladle level at all times to prevent molten metal from spilling out.

- Have a spill kit ready in case of an accident.

4. How do you troubleshoot common problems with ladle pullers?

Common problems with ladle pullers include:

- The puller is not pulling the ladle.

- The puller is pulling the ladle too slowly.

- The puller is making a lot of noise.

- The puller is leaking hydraulic fluid.

To troubleshoot these problems, I would:

- Check the power supply to the puller.

- Check the hydraulic fluid level.

- Check the condition of the hydraulic hoses.

- Inspect the puller for any damage.

5. What is your experience with working in a team environment?

In my previous role as a Ladle Puller, I worked closely with a team of other operators to ensure the smooth and efficient operation of the ladle crane. I was responsible for coordinating with the crane operator to position the ladle correctly and for communicating with the team members on the ground to ensure that the ladle was safely pulled and poured.

6. What is your experience with operating heavy machinery?

In addition to my experience operating ladle pullers, I have also operated a variety of other heavy machinery, including forklifts, cranes, and bulldozers. I am comfortable operating heavy machinery and I have a strong understanding of the safety protocols involved.

7. What are your physical strengths?

As a Ladle Puller, I am required to be physically strong to be able to pull heavy ladles of molten metal. I am also required to be able to stand for long periods of time and to be able to work in a hot and noisy environment.

8. What are your weaknesses?

One of my weaknesses is that I can be impatient at times. I am also not very good at working in a team environment.

9. Why do you want to work for our company?

I am interested in working for your company because I am impressed by your commitment to safety and your focus on employee development. I am confident that I can be a valuable asset to your team and I am eager to learn more about your company and the Ladle Puller position.

10. What are your salary expectations?

My salary expectations are commensurate with my experience and qualifications. I am confident that I can provide value to your company and I am willing to negotiate a salary that is fair to both parties.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ladle Puller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ladle Puller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Ladle Puller is responsible for handling and transporting molten metal from a furnace to casting areas within a foundry environment. Their key responsibilities include:

1. Transporting Molten Metal

Ladle Pullers are responsible for transporting molten metal in ladles, which are large containers, from the furnace to casting areas. They must follow proper safety procedures to ensure the safe and efficient movement of molten metal.

- Operate overhead cranes to lift and move ladles filled with molten metal.

- Maintain a steady and controlled pace while transporting molten metal to avoid spills and accidents.

2. Pouring Molten Metal

Once the molten metal is transported to the casting area, Ladle Pullers assist in pouring the metal into molds or casting machines. They work closely with other foundry personnel to ensure the accurate and efficient pouring of molten metal.

- Control the pouring of molten metal into molds or casting machines, ensuring proper filling and avoiding over-pouring or spills.

- Coordinate with foundry workers to determine pouring schedules and ensure a smooth production process.

3. Equipment Maintenance

Ladle Pullers are responsible for inspecting, maintaining, and troubleshooting equipment used in their daily tasks. This includes checking overhead cranes, ladles, and other foundry equipment for any potential issues.

- Perform regular inspections of equipment, such as overhead cranes and ladles, to ensure they are in good working condition.

- Identify and troubleshoot any problems with equipment and take appropriate actions to resolve them.

4. Compliance with Safety Regulations

Working with molten metal requires strict adherence to safety regulations. Ladle Pullers must prioritize safety in all aspects of their work, ensuring compliance with established safety protocols.

- Follow all established safety procedures to prevent accidents and protect themselves and others.

- Wear appropriate personal protective equipment (PPE), such as heat-resistant clothing, gloves, and safety glasses.

Interview Tips

To ace an interview for a Ladle Puller position, it is crucial to prepare thoroughly. Here are some key tips to help you stand out:

1. Research the Company and Industry

Before the interview, take time to research the foundry company and the industry. Familiarize yourself with their products, processes, and safety regulations. This knowledge will demonstrate your interest and understanding of the role.

- Visit the company’s website and social media pages to learn about their operations.

- Read industry news and articles to stay updated on current trends and technologies.

2. Emphasize Safety and Experience

Safety is paramount in foundry operations. Highlight your understanding and commitment to safety regulations. Additionally, emphasize your experience in handling molten metal, operating overhead cranes, and maintaining foundry equipment.

- Provide specific examples of your safety practices and how you have contributed to a safe work environment.

- Quantify your experience, such as the number of ladles you have handled or the tonnage of molten metal you have transported.

3. Demonstrate Physical and Technical Skills

Ladle Pullers require both physical and technical skills. Showcase your strength, endurance, and ability to work in a fast-paced, physically demanding environment. Also, demonstrate your technical knowledge of foundry equipment and processes.

- Be prepared to discuss your physical fitness and stamina, as well as your experience in handling heavy loads.

- Highlight your understanding of foundry equipment, such as overhead cranes, ladles, and casting machines.

4. Prepare for Behavioral Questions

Behavioral interview questions are commonly used to assess your work style and personality. Prepare for questions that delve into your teamwork abilities, problem-solving skills, and conflict resolution strategies.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions.

- Provide specific examples from your previous work experience that demonstrate your relevant skills and qualities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ladle Puller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!