Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ladle Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

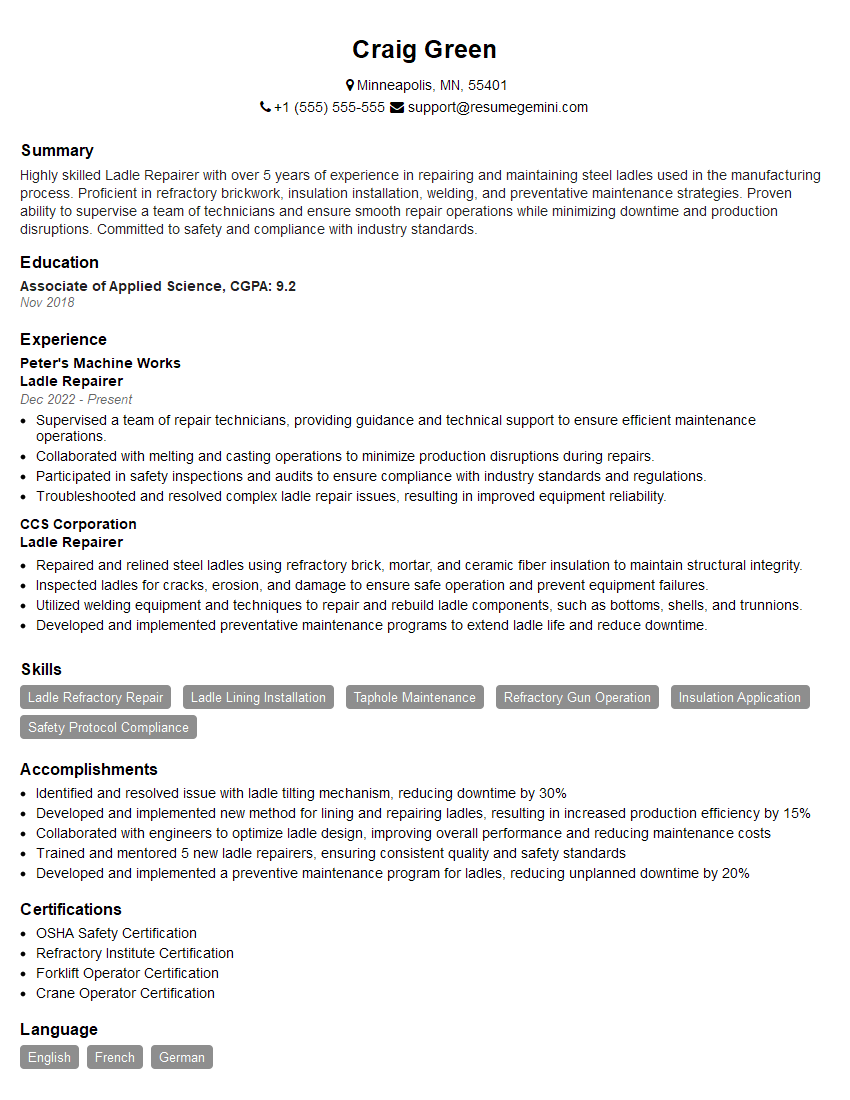

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ladle Repairer

1. What are the different types of refractory materials used in ladle repairs?

There are various types of refractory materials used in ladle repairs, including:

- Magnesia-carbon bricks

- Dolomite bricks

- Magnesite bricks

- Zirconia bricks

- Alumina bricks

- Graphite bricks

2. What is the process of patching a ladle bottom?

Cold Patching

- Prepare the surface by removing any slag or debris.

- Apply a layer of adhesive.

- Place the patch material over the adhesive.

- Compact the patch material.

- Allow the patch material to cure.

Hot Patching

- Preheat the ladle bottom to the appropriate temperature.

- Apply a layer of molten patch material.

- Compact the patch material.

- Allow the patch material to cool and solidify.

3. How do you determine the thickness of a ladle lining?

The thickness of a ladle lining can be determined using the following methods:

- Ultrasonic testing: This method uses sound waves to measure the thickness of the lining.

- Radiography: This method uses X-rays to measure the thickness of the lining.

- Core drilling: This method involves drilling a hole through the lining to measure its thickness.

4. What are the common causes of ladle refractory failure?

The common causes of ladle refractory failure include:

- Thermal stress

- Mechanical stress

- Chemical attack

- Corrosion

- Erosion

- Spalling

5. How do you inspect a ladle for refractory damage?

A ladle can be inspected for refractory damage using the following methods:

- Visual inspection: This involves looking for cracks, spalls, or other damage to the lining.

- Ultrasonic testing: This method uses sound waves to detect damage to the lining.

- Radiography: This method uses X-rays to detect damage to the lining.

6. What are the different methods of ladle preheating?

The different methods of ladle preheating include:

- Gas burners

- Electric heaters

- Induction heaters

- Microwave heaters

7. What are the safety precautions that must be taken when working on a ladle repair?

The safety precautions that must be taken when working on a ladle repair include:

- Wearing appropriate personal protective equipment (PPE)

- Ensuring the ladle is properly supported

- Using proper lifting equipment

- Working in a well-ventilated area

- Following all safety instructions

8. What are the different types of ladle repairs?

The different types of ladle repairs include:

- Bottom repairs

- Shell repairs

- Tapping hole repairs

- Lining repairs

9. What are the benefits of using robotic ladle repair systems?

The benefits of using robotic ladle repair systems include:

- Increased safety

- Improved quality

- Reduced downtime

- Lower costs

10. What are the challenges of working as a ladle repairer?

The challenges of working as a ladle repairer include:

- Working in a hazardous environment

- Dealing with heavy and awkward equipment

- Working on irregular schedules

- Exposure to extreme temperatures

- Working with hazardous materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ladle Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ladle Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ladle Repairers are responsible for maintaining and repairing ladles, which are large vessels used to transport molten metal in steel mills and foundries. Their duties involve:

1. Ladle Inspection and Repair

Conduct regular inspections of ladles to identify any damage or wear and tear.

Plan and execute repairs, such as welding, patching, or relining the ladle.

Inspect and maintain hydraulic equipment, such as swing arms, trunnions, and tilting devices.

2. Equipment Operation and Maintenance

Operate cranes and other equipment to move and position ladles.

Perform preventative maintenance on equipment, including lubricating bearings, checking fluid levels, and replacing worn parts.

Monitor and adjust electrical and control systems.

3. Safety and Environmental Compliance

Adhere to established safety protocols and guidelines.

Ensure that repairs are conducted in a safe and environmentally responsible manner.

Maintain a clean and organized workspace.

4. Quality Control

Inspect repaired ladles to ensure they meet quality and performance standards.

Document repairs and maintain records.

Coordinate with other departments to ensure timely repair and return of ladles to production.

Interview Tips

Preparing thoroughly for a Ladle Repairer interview can significantly increase your chances of success. Here are some tips to consider:

1. Research the Company and Role

Research the company’s website, industry news, and social media to gain insights into their culture, values, and operations.

Carefully review the job description and identify the key responsibilities and qualifications.

2. Highlight Your Experience and Skills

Quantify your experience in ladle repair and maintenance, providing specific examples of projects you’ve successfully completed.

Demonstrate your proficiency in welding, hydraulics, electrical systems, and other relevant areas.

Emphasize your commitment to safety and quality control.

3. Prepare for Technical Questions

Expect questions about specific technical aspects of ladle repair, such as welding techniques, heat treatment processes, and safety protocols.

Review common ladle repair procedures and be prepared to discuss your understanding of the industry.

4. Showcase Your Work Ethic and Teaming Abilities

Ladle repairers work in demanding environments, requiring strong physical stamina and attention to detail.

Highlight your ability to work independently and as part of a team.

Provide examples of how you have overcome challenges and contributed to team successes.

5. Dress Appropriately and Punctually

First impressions matter. Dress professionally and arrive for your interview on time.

This demonstrates respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ladle Repairer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!