Feeling lost in a sea of interview questions? Landed that dream interview for Laminated Plastic Tabletop Molding Wrapper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Laminated Plastic Tabletop Molding Wrapper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

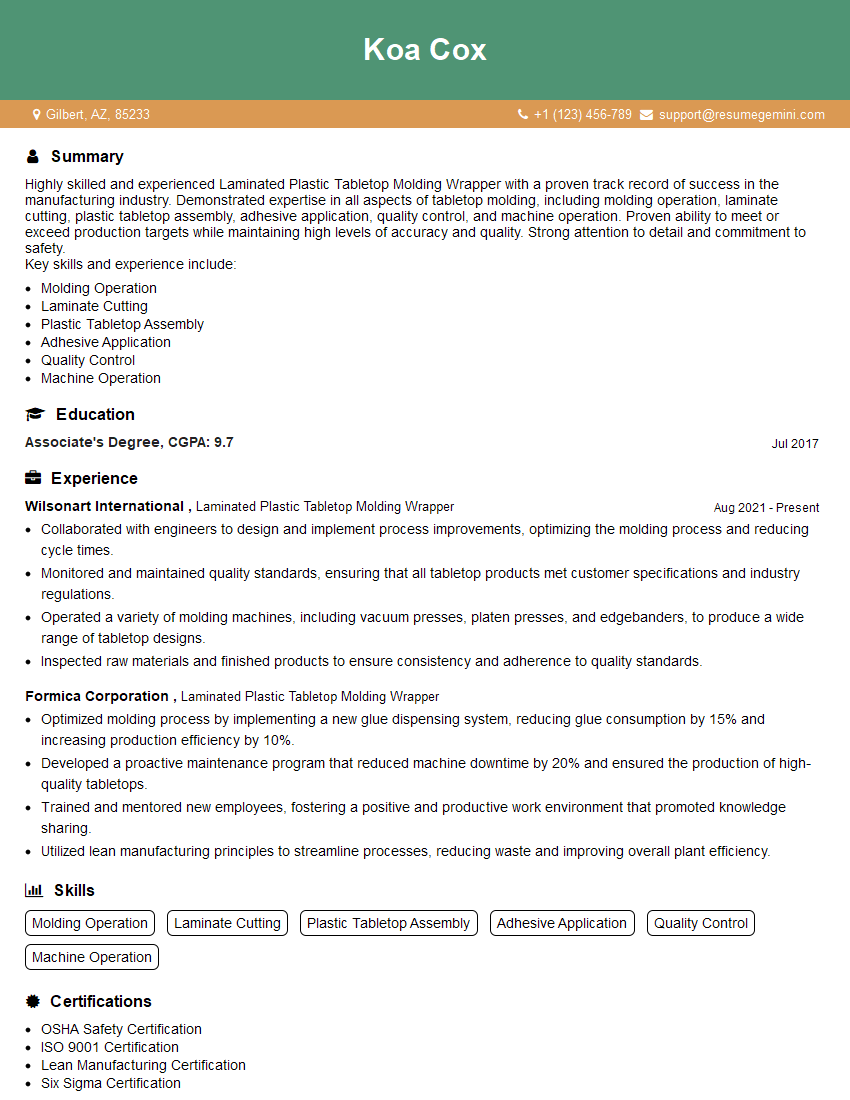

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Laminated Plastic Tabletop Molding Wrapper

1. Laminated plastic tabletop molding wrappers have several types of resins. Can you explain the differences in epoxy, phenolic and polyester resins?

- Epoxy resins: These resins are known for their excellent mechanical strength, chemical resistance, and adhesion properties. They are often used in high-performance applications, such as aerospace and automotive parts.

- Phenolic resins: These resins are known for their electrical insulation properties and heat resistance. They are often used in electrical components, such as circuit boards and switches.

- Polyester resins: These resins are known for their low cost and ease of processing. They are often used in general-purpose applications, such as fiberglass reinforced plastics and boat hulls.

2. What are the key factors to consider when selecting a laminated plastic tabletop molding wrapper?

The critical factors to consider when selecting a laminated plastic wrapper include:

- Material thickness: The thickness of the material will affect its strength and durability. Thicker materials are more robust but also more expensive.

- Type of resin: The type of resin used will affect the material’s properties. Epoxy resins are more expensive but offer better performance than phenolic or polyester resins.

- Surface finish: The surface finish can affect the material’s appearance and resistance to wear and tear. Glossy finishes are more reflective and easier to clean, but they are also more susceptible to scratches.

- Cost: The cost of the material is an important consideration. Thicker materials, epoxy resins, and glossy finishes are all more expensive.

3. How do you ensure the quality of laminated plastic tabletop molding wrappers?

To ensure the quality of laminated plastic wrapper, several steps can be taken:

- Raw material inspection: The raw materials used should be inspected to ensure they meet the required specifications.

- Process control: The manufacturing process should be closely controlled to ensure that the material is produced according to the required standards.

- Finished product testing: The finished product should be tested to ensure that it meets the required performance specifications.

4. What are the common problems that can occur during the production of laminated plastic tabletop molding wrappers?

- Delamination: This occurs when the layers of the material separate. It can be caused by several factors, such as poor adhesion between the layers, excessive heat or pressure during the molding process, or exposure to solvents.

- Cracking: This can be caused by several factors, such as thermal stress, mechanical stress, or exposure to chemicals.

- Warpage: This can be caused by uneven heating or cooling during the molding process or exposure to moisture.

- Discoloration: This can be caused by several factors, such as exposure to UV light, heat, or chemicals.

5. How do you troubleshoot problems that occur during the production of laminated plastic tabletop molding wrappers?

To troubleshoot problems that occur during the production of laminated plastic molding wrappers, the following steps can be taken:

- Identify the problem: The first step is to identify the problem that is occurring. This can be done by visually inspecting the material or by conducting tests.

- Determine the cause: Once the problem has been identified, the next step is to determine the cause. This can be done by considering the factors that could have contributed to the problem.

- Take corrective action: Once the cause of the problem has been determined, corrective action can be taken to prevent the problem from recurring.

6. What are the safety precautions that should be taken when working with laminated plastic tabletop molding wrappers?

- Wear appropriate personal protective equipment (PPE): This includes gloves, safety glasses, and a respirator.

- Handle the material with care: The material should be handled with care to avoid damaging it.

- Store the material properly: The material should be stored in a cool, dry place away from heat and sunlight.

- Dispose of the material properly: The material should be disposed of according to local regulations.

7. What are the latest trends in the laminated plastic tabletop molding wrapper industry?

- Increased demand for sustainable materials: There is a growing demand for laminated plastic made from sustainable materials, such as recycled content or plant-based materials.

- Development of new technologies: New technologies are being developed to improve the performance and efficiency of laminated plastic molding wrappers.

- Expansion into new markets: Laminated plastic tabletop molding wrappers are being used in various applications, such as automotive, electronics, and construction.

8. What are the challenges facing the laminated plastic tabletop molding wrapper industry?

- Rising raw material costs: The cost of raw materials for laminated plastic molding wrappers has been rising in recent years.

- Increased competition: There is increasing competition from other materials, such as metal and glass.

- Regulatory changes: Government regulations are becoming more stringent to protect the environment and human health.

9. What is your experience with laminated plastic tabletop molding wrappers?

Explain your experience working with laminated plastic tabletop molding wrappers. Discuss the different types of materials you have worked with, the processes you have used, and the challenges you have encountered.

10. Why are you interested in working for our company?

Explain why you are interested in working for our company. Discuss our company’s reputation, the products we offer, and the opportunities for growth.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Laminated Plastic Tabletop Molding Wrapper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Laminated Plastic Tabletop Molding Wrapper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Laminated Plastic Tabletop Molding Wrapper, you will be responsible for the molding and wrapping of laminated plastic tabletops. This will entail adhering to established safety protocols, maintaining a clean and organized work area, and operating machinery to efficiently produce high-quality tabletops.

1. Observe Safety Procedures

It is imperative that you prioritize safety in the workplace. This includes wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a hard hat. You must also adhere to established safety guidelines and report any potential hazards or accidents to your supervisor promptly.

2. Maintain a Clean and Organized Work Area

A tidy and organized work area contributes to both efficiency and safety. You are responsible for keeping your workspace clean and free of debris. This includes regularly sweeping and mopping floors, wiping down surfaces, and properly disposing of waste materials.

3. Operate Machinery for Tabletop Molding and Wrapping

You will be operating specialized machinery to mold and wrap laminated plastic tabletops. This involves setting up the machine, loading the materials, and monitoring the process to ensure that the tabletops are produced according to specifications. You must also perform regular maintenance and cleaning of the machinery to ensure its optimal performance.

4. Inspect Finished Tabletops and Resolve Defects

Once the tabletops have been molded and wrapped, you will inspect them for any defects or imperfections. If you identify any issues, you must take the necessary steps to resolve them promptly and efficiently. This may involve re-molding or re-wrapping the tabletop, or repairing any minor defects.

Interview Tips

To help you ace your interview for the Laminated Plastic Tabletop Molding Wrapper position, consider the following tips:

1. Research the Company and Position

Demonstrate your enthusiasm and interest in the role by researching the company and the specific position. Familiarize yourself with the company’s values, mission statement, and products or services. This knowledge will assist you in tailoring your answers to the interviewer’s questions and showcasing your understanding of the company’s culture and goals.

2. Practice Your Responses

Take time to prepare your responses to common interview questions. Practice speaking clearly and concisely, ensuring that your answers are relevant to the job requirements. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples of your experiences and accomplishments.

3. Highlight Relevant Skills and Experience

Throughout the interview, emphasize how your skills and experience align with the job responsibilities. Provide specific examples of your ability to operate machinery, maintain a clean work area, and inspect finished products. Be prepared to discuss your problem-solving abilities and how you handle challenges in the workplace.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. Prepare questions that relate to the company’s growth plans, sustainability initiatives, or the specific role you would be playing in the team. This not only shows that you are invested in the company’s success but also allows you to gather additional information about the position and the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Laminated Plastic Tabletop Molding Wrapper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!