Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Laminating Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

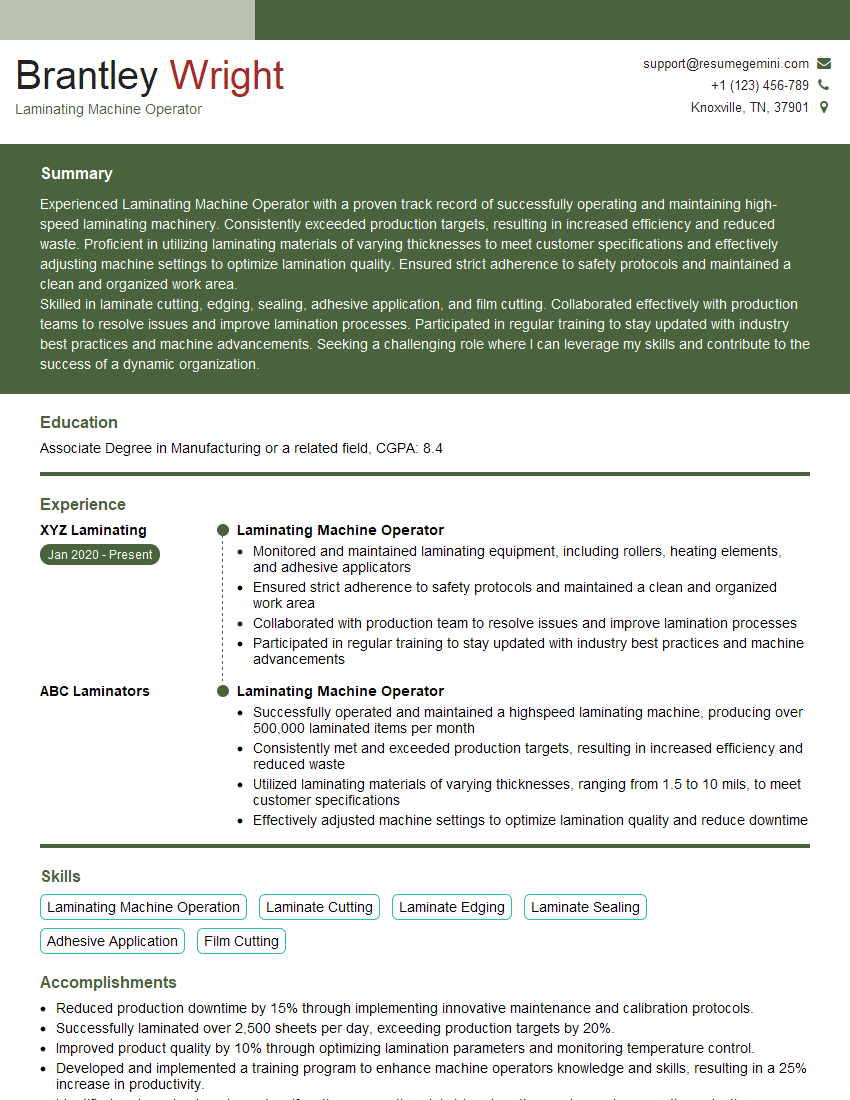

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Laminating Machine Operator

1. What are the different types of laminating machines and their applications?

There are various types of laminating machines, each suited for specific applications:

- Roll laminators: Designed for high-volume, continuous lamination of documents, posters, and other flat materials.

- Pouch laminators: Ideal for laminating small to medium-sized items like ID cards, menus, and photographs.

- Industrial laminators: Used for heavy-duty applications, such as laminating large sheets of metal, plastic, or wood.

- Floor laminators: Stand-alone machines designed for high-capacity lamination of flooring materials.

2. Describe the basic steps involved in the lamination process.

The typical lamination process comprises the following steps:

Laminating with roll laminators:

- Insert the laminating film into the machine.

- Feed the document or material to be laminated.

- Control temperature and pressure to adhere the film to the substrate.

Laminating with pouch laminators:

- Place the item to be laminated inside a laminating pouch.

- Insert the pouch into the laminator.

- Adjust heat and pressure settings to seal the pouch.

3. How do you calibrate and maintain a laminating machine?

Calibrating and maintaining laminating machines involves several critical steps:

- Calibrating temperature: Using a temperature probe, adjust the machine’s temperature to match the recommended setting for the film being used.

- Calibrating pressure: Set the pressure rollers to the appropriate pressure for the desired lamination quality.

- Cleaning: Regularly clean the rollers, guides, and heating elements to prevent film buildup and ensure proper operation.

- Lubrication: Lubricate moving parts as per the manufacturer’s guidelines to reduce friction and extend machine life.

4. What types of film are commonly used in lamination and their properties?

Common types of laminating film include:

- Polyester (PET): Clear and durable, resistant to moisture and chemicals, suitable for most applications.

- Oriented polypropylene (OPP): High clarity, tear-resistant, and moisture-resistant, often used for food packaging.

- Polyethylene (PE): Flexible and heat-sealable, but less durable than PET or OPP, used for temporary protection.

- Aluminum foil: Opaque and moisture-proof, used for packaging and insulation.

5. What factors influence the laminate’s quality and strength?

Several factors affect the quality and strength of the laminate:

- Film thickness: Thicker films provide greater protection and durability.

- Adhesive quality: The adhesive used to bond the film to the substrate plays a crucial role in strength.

- Temperature and pressure: Proper control of temperature and pressure during lamination ensures optimal bonding.

- Surface preparation: Cleaning and preparing the surface before lamination improves adhesion and bond strength.

6. How do you troubleshoot common problems with laminating machines?

Common problems with laminating machines include:

- Wrinkled or bubbled laminate: Incorrect temperature or pressure, dirty rollers, or poor surface preparation.

- Laminate peeling off: Insufficient adhesive or poor bonding due to incorrect temperature or pressure.

- Film jamming: Misaligned rollers, incorrect film loading, or debris buildup.

- Malfunctioning temperature control: Faulty temperature sensor or heating element.

7. How do you handle large-volume lamination projects efficiently?

For large-volume projects, efficiency can be improved by:

- Using industrial laminators: High-capacity machines designed for continuous operation.

- Optimizing workflow: Minimizing handling time by organizing materials and equipment.

- Batch processing: Laminating multiple items at once to reduce machine setup time.

- Automated systems: Utilizing conveyor belts or other automated equipment to streamline the process.

8. What safety precautions should be taken when operating a laminating machine?

To ensure safety, it’s crucial to:

- Follow manufacturer’s instructions: Carefully read and adhere to the operating manual.

- Wear appropriate PPE: Gloves and safety glasses to protect from heat and potential debris.

- Keep the area clean: Remove any flammable materials and keep the machine free of debris.

- Avoid touching hot surfaces: Allow the machine to cool before handling.

- Be aware of electrical hazards: Ensure proper grounding and avoid overloading circuits.

9. How do you stay updated with the latest advancements in laminating technology?

To keep abreast of advancements, I:

- Attend industry trade shows: Visit exhibitions to see new products and learn about emerging trends.

- Read industry publications: Subscribe to magazines and online resources for technical updates.

- Network with professionals: Connect with other laminators and industry experts to exchange knowledge and best practices.

- Research online: Utilize search engines and online forums to gather information about new technologies.

10. What differentiates a skilled laminating machine operator from an average one?

- Expertise in machine operation: Thorough understanding of laminating machines, their functions, and troubleshooting techniques.

- Attention to detail: Meticulous in ensuring high-quality laminates, free from defects.

- Efficiency and productivity: Ability to handle large-volume projects while maintaining accuracy and speed.

- Safety consciousness: Prioritizes safety procedures and maintains a clean and hazard-free work environment.

- Adaptability to different materials: Expertise in laminating various substrates, including paper, plastic, metal, and wood.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Laminating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Laminating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Laminating Machine Operator is responsible for operating laminating machines to bond materials together. The operator ensures the smooth functioning of the machine and consistently produces high-quality laminated products. Key job responsibilities include:1. Machine Operation

Operate and monitor laminating machines to bond various materials, such as paper, plastic, and metal.

- Set up and adjust machine settings according to specific product requirements.

- Load and unload materials into and out of the laminating machine.

2. Quality Control

Inspect laminated products for defects and ensure they meet quality standards.

- Check for proper adhesion, surface finish, and dimensional accuracy.

- Identify and correct any production issues affecting product quality.

3. Material Handling

Receive and handle incoming materials, including substrates, adhesives, and films.

- Inspect materials for damage or defects before using them in the laminating process.

- Store and organize materials in a safe and efficient manner.

4. Machine Maintenance

Perform basic maintenance tasks on laminating machines to ensure optimal performance.

- Clean and lubricate machine components as per manufacturer’s instructions.

- Identify and report any mechanical issues or malfunctions to supervisors.

Interview Tips

Preparing for a Laminating Machine Operator interview requires thorough research, practice, and a well-structured approach. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and values. Understand the specific requirements and responsibilities of the Laminating Machine Operator position.

- Visit the company website and read about their mission, products, and team.

- Search for news articles or industry reports related to the company to gain insights into their recent developments.

2. Practice Answering Common Interview Questions

Anticipate potential interview questions and prepare thoughtful answers. Consider using the STAR method (Situation, Task, Action, Result) to demonstrate your skills and experience.

- Example Question: Describe a time when you encountered a production issue with a laminating machine. How did you resolve it?

- Example Answer: In a previous role, I encountered a situation where the laminating machine produced inconsistent adhesion. I identified a faulty temperature sensor as the root cause. I replaced the sensor, recalibrated the machine, and successfully resolved the issue, ensuring optimal product quality.

3. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating laminating machines, quality control procedures, and material handling techniques. Quantify your accomplishments whenever possible.

- Example: “In my previous role, I consistently exceeded production quotas by 15% while maintaining high product quality standards.”

4. Ask Thoughtful Questions

Asking informed questions at the end of the interview demonstrates your interest and engagement. Prepare a few questions that show your enthusiasm for the role and the company.

- Example Question: “Could you describe the company’s plans for future product development and how they may impact the laminating process?”

5. Dress Professionally and Arrive on Time

First impressions matter. Dress in business attire and arrive punctually for your interview. Punctuality and professionalism convey respect and seriousness about the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Laminating Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Laminating Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.