Are you gearing up for an interview for a Lamination Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lamination Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

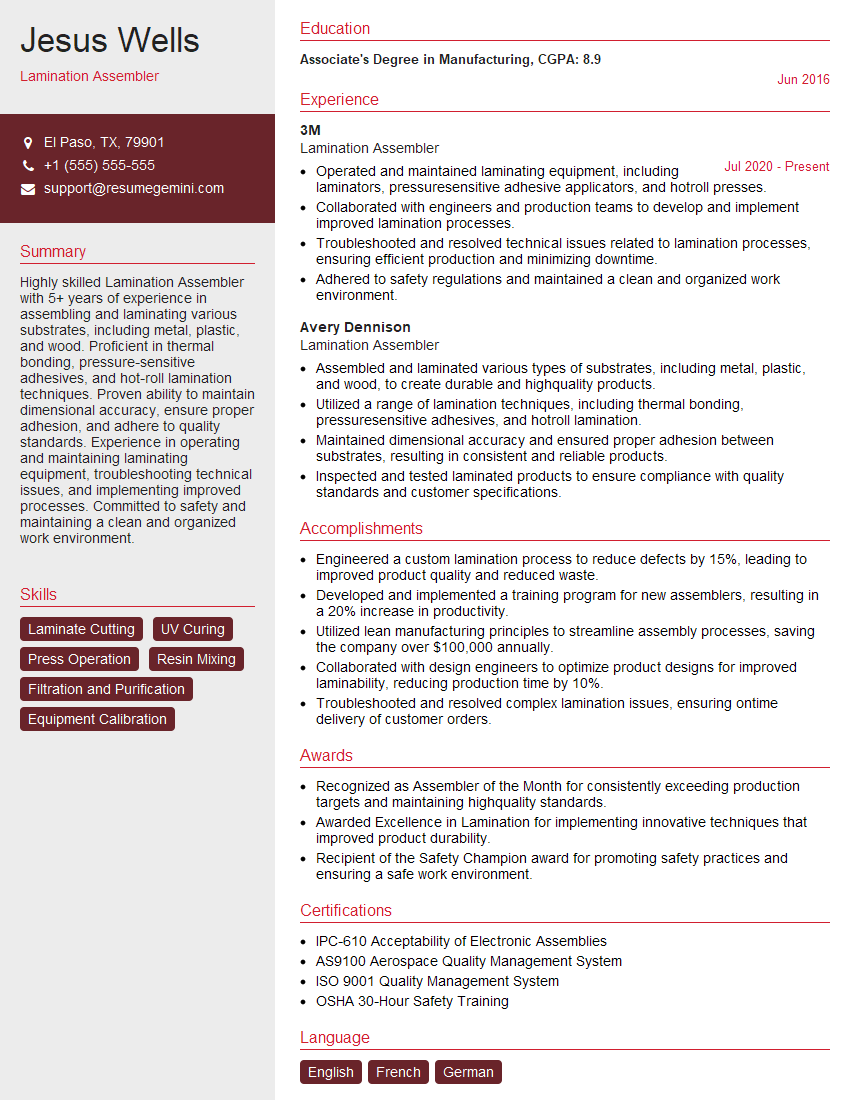

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lamination Assembler

1. Explain the process of laminating a core?

The process of laminating a core involves the following steps:

- Preparing the core: The core is first cleaned and prepared by removing any burrs or imperfections. It may also be pre-heated to improve the adhesion of the laminate.

- Applying the laminate: The laminate is then applied to the core using a variety of methods, such as hand lay-up, vacuum bagging, or autoclave molding. The laminate can be made of various materials, such as fiberglass, carbon fiber, or prepreg.

- Curing the laminate: After the laminate has been applied, it is cured by exposing it to heat and pressure. This process hardens the resin and bonds the laminate to the core.

- Inspecting the laminate: Once the laminate has been cured, it is inspected for defects, such as voids, delaminations, or cracks.

2. What are the different types of laminates used?

- Fiberglass: Fiberglass is a strong and lightweight material that is commonly used in the construction of boats, airplanes, and automotive parts.

- Carbon fiber: Carbon fiber is an even stronger and lighter material than fiberglass, but it is also more expensive. It is often used in high-performance applications, such as racing cars and aerospace components.

- Prepreg: Prepreg is a type of laminate that is made of pre-impregnated resin and fabric. It is often used in the construction of composite parts, such as wings and fuselages.

3. What are the key factors that affect the quality of a laminate?

- The quality of the core: The core should be strong, lightweight, and free of defects.

- The quality of the laminate: The laminate should be made of high-quality materials and free of defects.

- The quality of the bonding: The bond between the core and laminate should be strong and durable.

- The quality of the curing: The curing process should be carefully controlled to ensure that the laminate is fully cured.

- The quality of the inspection: The laminate should be carefully inspected for defects before it is used.

4. What are the common problems that can occur during the lamination process?

- Voids: Voids are empty spaces in the laminate that can weaken the bond between the core and laminate.

- Delaminations: Delaminations are separations between the core and laminate.

- Cracks: Cracks can occur in the laminate due to stress, impact, or fatigue.

- Wrinkles: Wrinkles can occur in the laminate due to improper application or curing.

- Foreign objects: Foreign objects, such as dirt, dust, or hair, can become embedded in the laminate during the lamination process.

5. How do you troubleshoot problems that occur during the lamination process?

- Voids: Voids can be eliminated by using a vacuum bag or autoclave to remove air from the laminate during the curing process.

- Delaminations: Delaminations can be prevented by using a primer to improve the adhesion between the core and laminate.

- Cracks: Cracks can be prevented by using a stress-relief layer or by reinforcing the laminate with additional layers of material.

- Wrinkles: Wrinkles can be prevented by using a squeegee or roller to smooth out the laminate during the application process.

- Foreign objects: Foreign objects can be prevented by keeping the work area clean and by using clean materials.

6. What are the safety precautions that should be taken when working with laminates?

- Wear protective clothing: Wear gloves, safety glasses, and a respirator when working with laminates.

- Use proper ventilation: Work in a well-ventilated area to avoid inhaling harmful fumes.

- Store chemicals safely: Store laminating resins and other chemicals in a safe and well-ventilated area.

- Dispose of waste properly: Dispose of waste laminates and chemicals in accordance with local regulations.

7. What are the different types of equipment used in the lamination process?

- Vacuum bag: A vacuum bag is used to remove air from the laminate during the curing process.

- Autoclave: An autoclave is a pressure vessel that is used to cure laminates under pressure.

- Stress-relief layer: A stress-relief layer is a layer of material that is used to reduce stress in the laminate.

- Squeegee: A squeegee is a tool that is used to smooth out the laminate during the application process.

- Roller: A roller is a tool that is used to apply pressure to the laminate during the curing process.

8. What are the different quality control procedures that are used in the lamination process?

- Visual inspection: The laminate is visually inspected for defects, such as voids, delaminations, or cracks.

- Non-destructive testing: Non-destructive testing methods, such as ultrasonic testing or radiography, can be used to detect defects in the laminate.

- Destructive testing: Destructive testing methods, such as tensile testing or flexural testing, can be used to determine the mechanical properties of the laminate.

9. What are the latest trends in the lamination industry?

- The use of new materials: New materials, such as carbon nanotubes and graphene, are being used to develop stronger and lighter laminates.

- The development of new processes: New processes, such as additive manufacturing, are being used to create complex laminates with improved performance.

- The use of automation: Automation is being used to improve the efficiency and quality of the lamination process.

10. What are your strengths and weaknesses as a lamination assembler?

My strengths as a lamination assembler include:

- Experience: I have several years of experience in the lamination industry and am familiar with all aspects of the process.

- Skills: I have strong skills in the use of laminating equipment and materials.

- Quality: I am committed to producing high-quality laminates and take pride in my work.

- Safety: I am aware of the safety hazards associated with the lamination process and take all necessary precautions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lamination Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lamination Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Lamination Assembler, your primary responsibility is to ensure the precise and efficient assembly of laminated products. Key aspects of your role include:

1. Laminate Assembly

You will be responsible for assembling various materials together using specialized adhesives and equipment to create laminated products, such as panels, countertops, and architectural components.

2. Material Handling

You will handle and move a variety of materials, including laminates, veneers, and substrates, while maintaining proper storage and inventory.

3. Equipment Operation

You will operate specialized machinery, such as laminating presses, cutters, and edgebanders, to process and assemble laminated products.

4. Quality Control

You will inspect and ensure the quality of laminated products by checking for defects, ensuring proper bonding, and maintaining quality standards.

Interview Tips

To ace your Lamination Assembler interview, consider the following tips:

1. Research the Company

Thoroughly research the company you are applying to, including its products, services, and industry reputation. This will help you demonstrate your genuine interest and understanding of the role.

2. Highlight Relevant Skills

Emphasize your experience in laminate assembly, material handling, equipment operation, and quality control. Provide specific examples of your proficiency in these areas.

3. Prepare for Technical Questions

Expect questions about laminate materials, assembly processes, equipment usage, and quality control measures. Familiarize yourself with industry terminology and best practices.

4. Showcase Attention to Detail

Highlight your ability to work precisely and pay attention to detail. This is crucial in ensuring the quality and accuracy of laminated products.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lamination Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!