Are you gearing up for an interview for a Lamination Builder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lamination Builder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

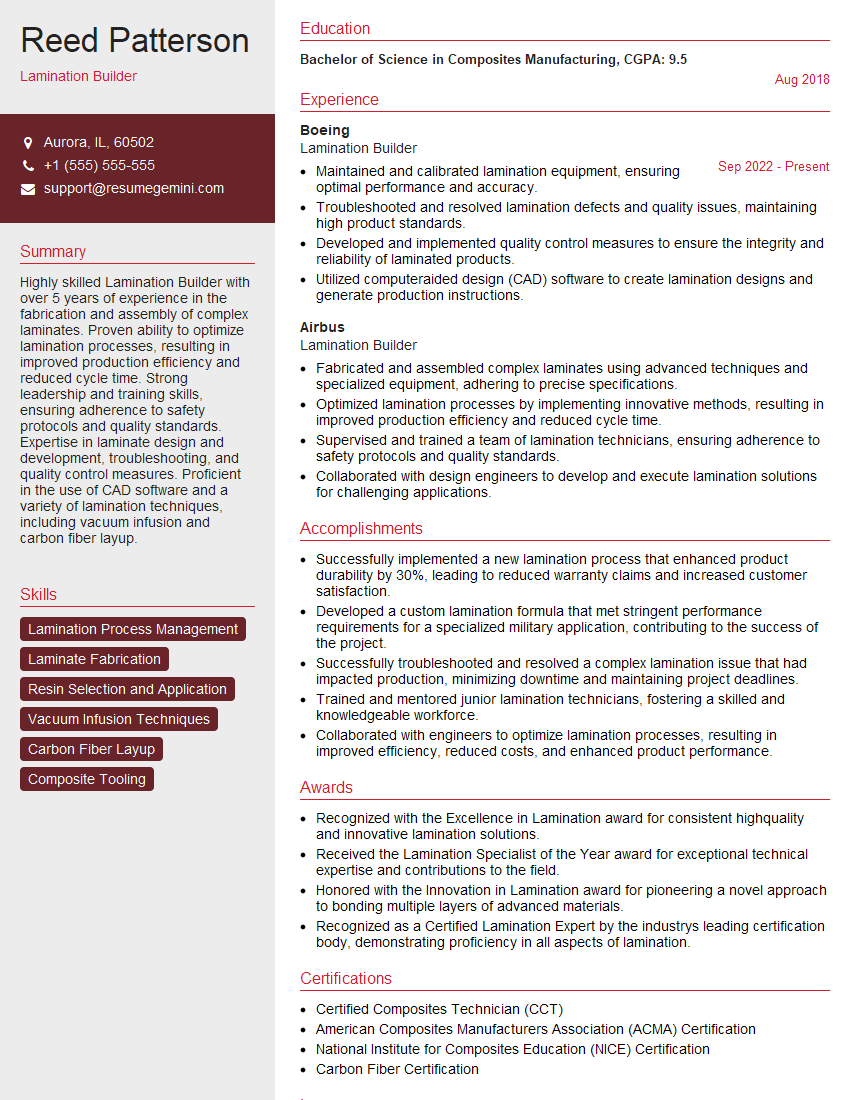

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lamination Builder

1. What are the different types of laminating materials and their applications?

- Polyester films

- Polypropylene films

- Metallized films

- Paper-based laminates

- Foil laminates

2. Explain the process of laminating.

Laminating Rollers

- Chrome rollers

- Rubber rollers

- Silicone rollers

Laminating Adhesives

- Water-based adhesives

- Solvent-based adhesives

3. What are the quality control measures you follow during the lamination process?

- Checking the tension of the laminating film

- Monitoring the temperature of the laminating rollers

- Checking the thickness of the laminated product

- Inspecting the surface of the laminated product for defects

4. What are the common problems that can occur during lamination and how do you resolve them?

- Bubbles in the laminate

- Wrinkles in the laminate

- Delamination

- Silvering

5. What are the safety precautions that you need to take when working with laminating equipment?

- Wear appropriate safety gear, such as gloves, safety glasses, and a dust mask

- Keep the work area clean and free of tripping hazards

- Never operate laminating equipment without proper training

6. What are the latest trends in lamination technology?

- The use of digital printing technology for lamination

- The development of new laminating adhesives that are more environmentally friendly

- The use of new laminating techniques that produce higher quality laminates

7. What are the different types of surface finishes that can be applied to laminated products?

- Gloss finish

- Matte finish

- Satin finish

- Embossed finish

8. What are the benefits of using laminated products?

- Increased durability

- Improved appearance

- Enhanced moisture resistance

- Increased strength

9. What are the different applications for laminated products?

- Packaging

- Signage

- Displays

10. What is your experience with laminating equipment?

- List the types of laminating equipment you have operated

- Describe your experience with setting up, operating, and maintaining laminating equipment

- Discuss any troubleshooting experience you have with laminating equipment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lamination Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lamination Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Materials Preparation and Handling

A Lamination Builder is responsible for prepping laminating materials such as films, adhesives, and substrates.

- Inspecting and sorting materials for defects and quality.

- Cutting and sizing materials according to specified dimensions and shapes.

- Cleaning, aligning, and stacking materials for lamination process.

2. Machine Operation and Maintenance

Operating and maintaining laminating machinery is a crucial aspect of the job.

- Setting up and calibrating laminating machines based on material specs.

- Loading, feeding, and monitoring materials through the lamination process.

- Performing regular maintenance tasks such as cleaning, lubrications, and minor repairs.

3. Quality Control and Inspection

Ensuring the quality of laminated products is a top priority.

- Conducting in-process and final inspections to identify defects or non-conformances.

- Measuring and recording product dimensions, thickness, and other specifications.

- Adhering to established quality standards and regulations.

4. Production Management

Optimizing production processes and meeting production targets is essential.

- Monitoring production schedules and adjusting as needed to meet deadlines.

- Identifying and addressing bottlenecks or inefficiencies in the process.

- Coordinating with other team members to ensure smooth production flow.

Interview Tips

To enhance your chances of success in the interview, consider these tips:

1. Research the Company and Role

Thoroughly review the company’s website, LinkedIn page, and industry news to gain insights into their business practices, culture, and values. Understanding the specific role and responsibilities will help you tailor your answers to the interviewer’s questions.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on experience in laminating processes, including machine operation, materials handling, and quality control. Quantify your accomplishments to showcase your impact. For instance, you could state that you “reduced production downtime by 15% through proactive maintenance.”

3. Prepare for Technical Questions

Expect questions about specific laminating techniques, machinery, and materials. Be ready to discuss your knowledge of adhesives, films, and pressure settings. You may also encounter questions about troubleshooting common production issues.

4. Showcase Your Problem-Solving Abilities

Interviewers value candidates who can think critically and find solutions. Share instances where you identified and resolved problems in a laminating environment. Explain your approach, the steps you took, and the results you achieved. This demonstrates your analytical and practical problem-solving skills.

5. Practice Your Communication Skills

Effective communication is crucial. Practice answering questions clearly and concisely, using specific examples to support your claims. Maintain eye contact, speak with confidence, and actively listen to the interviewer’s questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lamination Builder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!