Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lamination Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

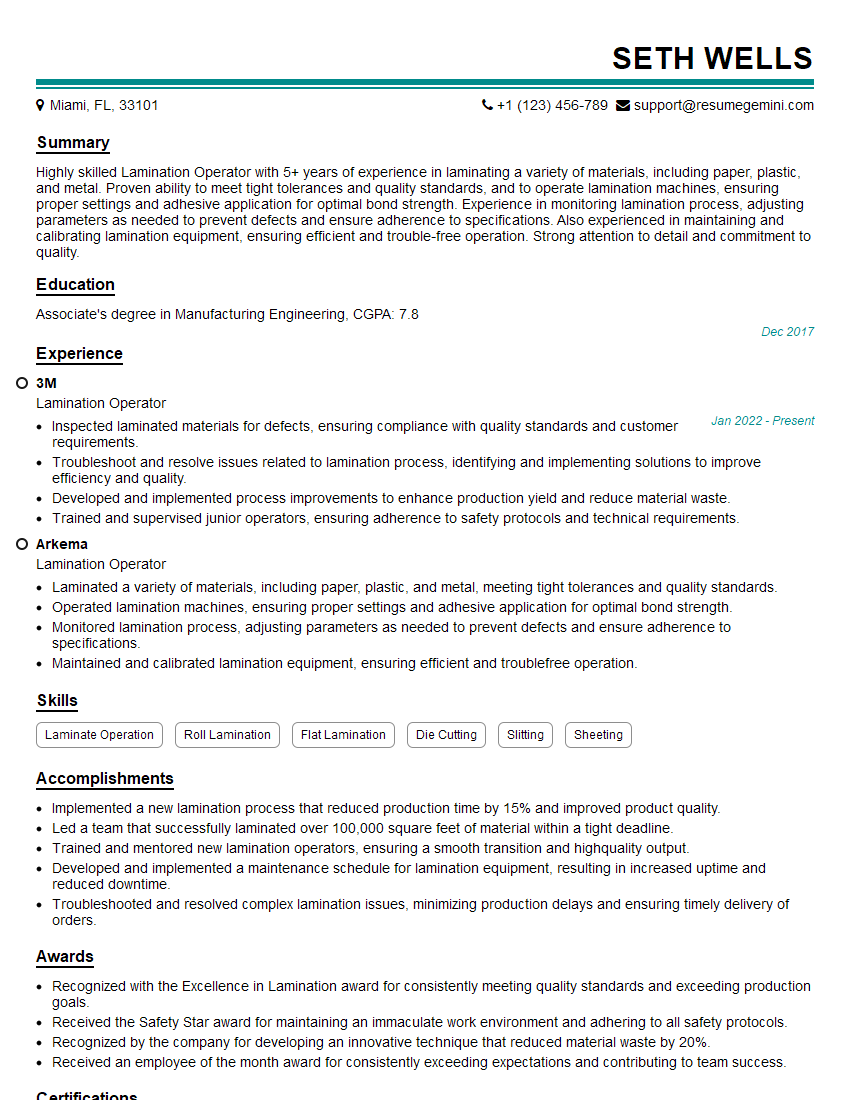

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lamination Operator

1. Explain the process of laminating materials?

Laminating involves bonding multiple layers of materials together using an adhesive or heat. The process typically includes the following steps:

- Preparing the materials: Cleaning and preparing the surfaces to be laminated.

- Applying adhesive: Applying an adhesive to one or both surfaces.

- Positioning the materials: Aligning and positioning the materials accurately.

- Bonding: Applying pressure and heat or using an adhesive to bond the materials together.

- Trimming and finishing: Trimming excess material and finishing the edges.

2. What types of materials can be laminated?

A wide range of materials can be laminated, including:

- Paper and cardboard

- Plastics (e.g., polyethylene, PET, PVC)

- Foils (e.g., aluminum, copper)

- Textiles

- Composites

3. What are the different types of laminating machines?

There are various types of laminating machines, including:

- Roll laminators: Suitable for small-scale applications, with materials fed through rollers.

- Pouch laminators: Use pre-sealed pouches to encapsulate materials, ideal for documents and photos.

- Flatbed laminators: Used for larger materials, with a flat surface for bonding.

- Industrial laminators: High-capacity machines designed for continuous production.

4. What factors affect the quality of lamination?

Several factors influence the quality of lamination:

- Material compatibility: Ensuring the materials to be laminated are compatible with the adhesive and process.

- Surface preparation: Proper cleaning and preparation of surfaces enhance adhesion.

- Adhesive selection: Choosing the appropriate adhesive based on material properties and application requirements.

- Temperature and pressure control: Maintaining optimal temperature and pressure during bonding is crucial.

- Equipment maintenance: Regularly servicing and calibrating laminating machines ensure consistent performance.

5. What are the common defects in lamination and how can they be prevented?

Some common defects in lamination include:

- Bubbles and wrinkles: Caused by improper degassing or insufficient pressure during bonding.

- Delamination: Occurs when the bond between layers weakens or fails.

- Warping: Can result from uneven shrinkage or expansion of materials.

- Discoloration: May be caused by chemical reactions or exposure to UV light.

- Preventing these defects involves careful material selection, proper surface preparation, and precise control of the laminating process.

6. How do you handle and store laminated materials?

Laminated materials require proper handling and storage to maintain their integrity:

- Storing in a dry and cool environment: Protect laminated materials from moisture and excessive heat.

- Avoiding direct sunlight: UV light can cause discoloration and degradation.

- Using protective packaging: Store laminated materials in protective sleeves or containers to prevent scratches and damage.

- Handling with care: Avoid bending or folding laminated materials to prevent cracking or delamination.

7. What safety precautions should be taken when working with laminating equipment?

When operating laminating equipment, it is essential to adhere to safety precautions:

- Wearing appropriate PPE: Use gloves, safety glasses, and a respirator if necessary.

- Ensuring proper ventilation: Adequate ventilation is crucial to prevent exposure to fumes or chemicals.

- Following equipment instructions: Familiarize yourself with the operating instructions and follow them carefully.

- Inspecting equipment regularly: Regularly check laminating equipment for any potential hazards or malfunctions.

- Reporting any issues: Promptly report any equipment problems or safety concerns to supervisors.

8. How do you maintain and troubleshoot laminating machines?

Maintaining and troubleshooting laminating machines involve several tasks:

- Regular cleaning: Keep machines clean to prevent adhesive buildup and ensure proper operation.

- Calibration and adjustment: Regularly calibrate equipment to ensure accurate temperature and pressure settings.

- Troubleshooting common issues: Identify and resolve common problems such as temperature fluctuations, material feeding issues, or bond failures.

- Preventive maintenance: Perform regular maintenance checks to identify and address potential issues before they become major problems.

- Calling for professional assistance: For complex or technical issues, it may be necessary to contact the manufacturer or a qualified technician for assistance.

9. What quality control measures do you follow to ensure the quality of laminated products?

Ensuring the quality of laminated products requires implementing quality control measures:

- Material inspection: Inspecting incoming materials to ensure they meet specifications.

- Process monitoring: Monitoring the laminating process to ensure it adheres to established parameters.

- Product testing: Conducting tests on finished products to assess their strength, durability, and appearance.

- Record-keeping: Maintaining records of quality control checks and test results for traceability and continuous improvement.

- Customer feedback: Gathering customer feedback to identify areas for improvement in product quality.

10. How do you stay up-to-date on the latest developments in laminating technology?

To stay up-to-date on advancements in laminating technology:

- Attending industry events: Participating in conferences and trade shows to learn about new products and techniques.

- Reading industry publications: Subscribing to magazines, journals, and online resources to stay informed about industry trends.

- Networking with professionals: Connecting with other laminating professionals to exchange knowledge and insights.

- Seeking training and certification: Pursuing training programs and certifications to enhance skills and knowledge in laminating.

- Staying informed about regulatory changes: Monitoring industry regulations and standards to ensure compliance and incorporate new requirements into processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lamination Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lamination Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lamination Operators are responsible for operating and maintaining lamination equipment to bond multiple layers of materials together. Some of the key responsibilities include:

1. Machine Operation and Maintenance

Starting, stopping, and monitoring lamination machines

- Making adjustments to control machine speed, temperature, and pressure

- Performing routine maintenance and troubleshooting

2. Material Handling

Loading and unloading materials into and out of the lamination machine

- Inspecting materials for defects and ensuring proper alignment

- Adjusting material tension to prevent wrinkles or tears

3. Quality Control

Inspecting laminated products for defects and ensuring they meet specifications

- Measuring product thickness, adhesion, and strength

- Maintaining records of product quality and identifying areas for improvement

4. Safety and Compliance

Adhering to safety regulations and following proper operating procedures

- Wearing appropriate personal protective equipment (PPE)

- Maintaining a clean and organized work area

Interview Tips

Preparing for an interview for a Lamination Operator position requires research and practice. Here are some tips to help you ace your interview:

1. Research the Company and Role

Gather information about the company’s industry, products, and culture.

- Understand the specific requirements of the Lamination Operator role.

- Tailor your answers to demonstrate how your skills and experience align with the position.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating lamination machines and handling materials.

- Provide specific examples of how you have resolved issues and ensured product quality.

- Discuss your knowledge of safety regulations and commitment to following them.

3. Demonstrate Attention to Detail

Lamination Operators must have a keen eye for detail to ensure product quality.

- Highlight your ability to identify and correct defects.

- Describe your methods for maintaining accurate records and monitoring product specifications.

4. Practice Answering Common Interview Questions

Prepare for common questions such as:

- “Tell me about your experience operating lamination machines.”

- “How do you ensure product quality and prevent defects?”

- “What are your safety protocols when operating lamination equipment?”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lamination Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.