Are you gearing up for a career in Lamination Spinner? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lamination Spinner and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

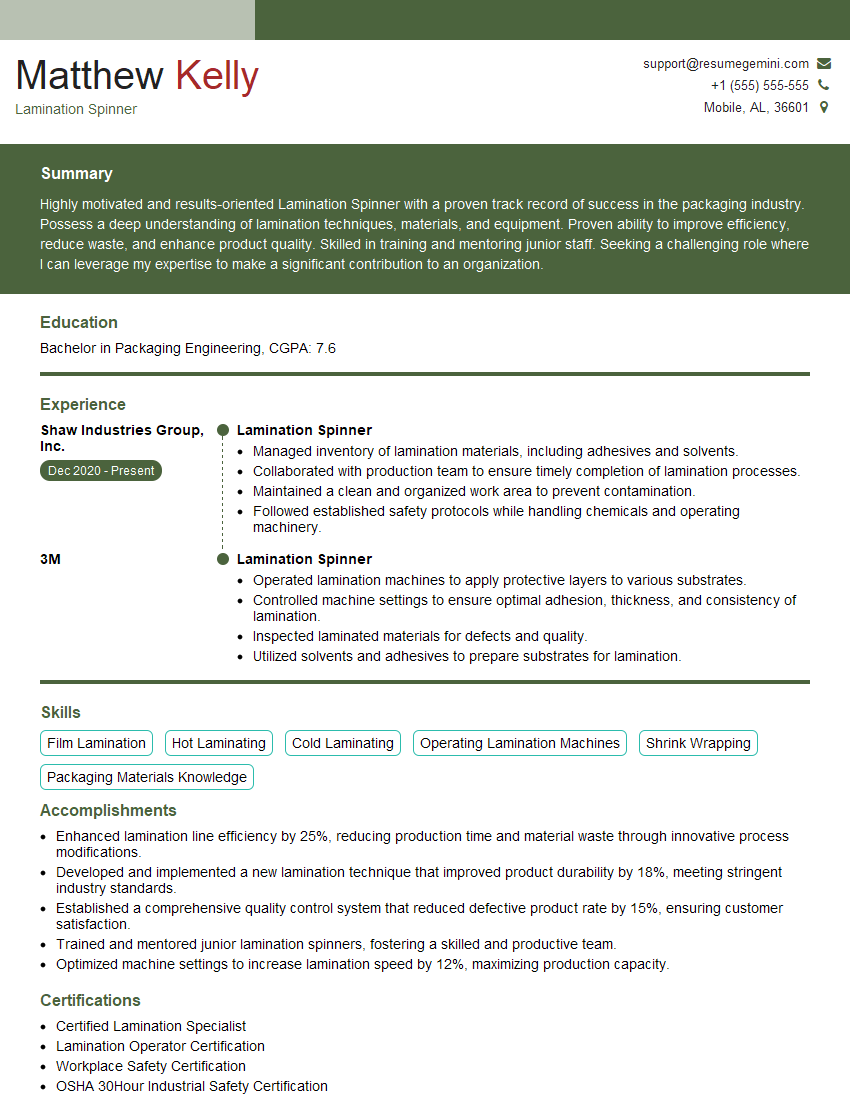

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lamination Spinner

1. Describe the process of setting up a lamination machine.

Sample Answer: To set up a lamination machine, I typically follow these steps:

- Prepare the lamination pouch by cutting it to the desired size.

- Place the document or item to be laminated in the pouch.

- Insert the pouch into the machine’s loading tray.

- Set the temperature and speed settings based on the pouch thickness and material.

- Start the lamination process.

2. What are the different types of laminating films available, and which one is best suited for a given project?

Sample Answer: Common types of laminating films include:

Glossy

- Provides a shiny, reflective finish.

- Ideal for documents that require a professional or eye-catching appearance.

Matte

- Produces a non-reflective, more subdued finish.

- Suitable for documents that will be frequently handled or written on.

3. What are the common challenges faced while laminating, and how can they be resolved?

Sample Answer: Challenges include:

- Air Bubbles: Ensure the pouch is properly sealed and remove any trapped air before lamination.

- Wrinkles: Use a laminator with adjustable temperature settings and avoid over-laminating.

- Misaligned Pouches: Align the document and pouch carefully before starting the process.

4. Explain the difference between cold and hot lamination.

Sample Answer: Cold lamination:

- Uses pressure and adhesive to bond the laminating film to the document.

- Produces a less durable finish suitable for short-term projects.

Hot lamination:

- Uses heat and pressure to create a strong bond between the film and document.

- Provides a more durable and professional finish.

5. What are the safety precautions to follow when using a laminating machine?

Sample Answer: Safety precautions include:

- Always read the operating instructions carefully.

- Keep the machine in a well-ventilated area.

- Avoid touching hot surfaces.

- Unplug the machine when not in use.

6. Describe the process of maintaining a lamination machine.

Sample Answer: Maintenance includes:

- Cleaning: Regularly wipe down the machine with a soft cloth to remove dust and debris.

- Lubrication: Lubricate moving parts as per the manufacturer’s recommendations.

- Calibration: Check the machine’s alignment and temperature settings regularly.

7. What are the different applications of laminated materials?

Sample Answer: Laminated materials are widely used in:

- Protecting documents (ID cards, certificates)

- Creating marketing materials (brochures, posters)

- Enhancing the durability of products (book covers, signage)

8. Discuss the factors to consider when choosing a lamination machine for a specific project.

Sample Answer: Considerations include:

- Document Size: Choose a machine that can accommodate the size of the documents you’ll be laminating.

- Frequency of Use: Consider the durability and capacity of the machine based on your usage frequency.

- Types of Materials: The machine should support the types of laminating films and materials you intend to use.

9. What are the environmental implications of laminating, and how can we mitigate them?

Sample Answer: Laminating involves the use of plastic films, which can have environmental impacts:

- Biodegradability: Laminating films are not biodegradable and can take hundreds of years to decompose.

- Recycling: Laminated materials are not easily recyclable and often end up in landfills.

Mitigation measures:

- Reduce: Use lamination only when necessary and limit the number of items laminated.

- Recycle: Check with local recycling facilities to see if they accept laminated materials.

10. Explain the role of a lamination spinner in the lamination process.

Sample Answer: The lamination spinner is responsible for:

- Installing, maintaining, and troubleshooting lamination machines.

- Producing high-quality laminated products.

- Ensuring compliance with safety regulations and environmental considerations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lamination Spinner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lamination Spinner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lamination Spinners are responsible for operating lamination machines to apply a protective layer to various materials. They play a crucial role in ensuring the quality and durability of laminated products.

1. Machine Operation

Operate lamination machines to apply a thin, transparent layer of plastic film to materials such as paper, cardboard, or textiles.

- Set up and adjust machine parameters, including temperature, speed, and tension, to achieve optimal lamination results.

- Monitor machine operation and make necessary adjustments to ensure smooth and efficient production.

2. Material Handling

Load and unload materials into and out of the lamination machine, ensuring proper alignment and feeding.

- Inspect materials for defects or damage before and after lamination.

- Maintain a clean and organized work area to prevent contamination or damage to materials.

3. Quality Control

Inspect laminated products for imperfections, such as bubbles, wrinkles, or delamination, and ensure they meet quality standards.

- Use measuring instruments and visual inspection techniques to assess product quality.

- Identify and resolve any issues or defects in the lamination process to maintain high quality.

4. Maintenance and Troubleshooting

Perform basic machine maintenance, such as cleaning, lubrication, and minor repairs.

- Troubleshoot and resolve minor machine malfunctions to minimize downtime.

- Report any major issues or maintenance requirements to supervisors for prompt attention.

Interview Tips

To ace an interview for a Lamination Spinner position, it’s essential to prepare effectively and showcase your skills and experience.

1. Research the Company and Role

Familiarize yourself with the company’s products, services, and industry standing. Research the specific job requirements and responsibilities to prepare tailored answers.

- Visit the company website and LinkedIn page for information on their business.

- Read industry articles and news to understand the latest trends and advancements in lamination.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience, such as machine operation, material handling, quality control, and troubleshooting. Provide specific examples that demonstrate your proficiency.

- Quantify your accomplishments and use action verbs to describe your contributions.

- Prepare examples of times when you identified and resolved quality issues or implemented process improvements.

3. Practice Your Answers

Prepare for common interview questions and practice answering them clearly and concisely. Consider potential technical questions related to lamination machines and processes.

- Anticipate questions about your understanding of different types of lamination films and their applications.

- Practice describing your approach to quality control and your experience with troubleshooting equipment.

4. Dress Professionally and Be Punctual

First impressions matter, so dress professionally and arrive on time for your interview. Maintain a positive and enthusiastic demeanor throughout the process.

- Choose clothing that is appropriate for a manufacturing environment, such as closed-toe shoes and comfortable work attire.

- Be respectful of the interviewer’s time and arrive a few minutes early to show your readiness.

Next Step:

Now that you’re armed with the knowledge of Lamination Spinner interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lamination Spinner positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini