Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lamination Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

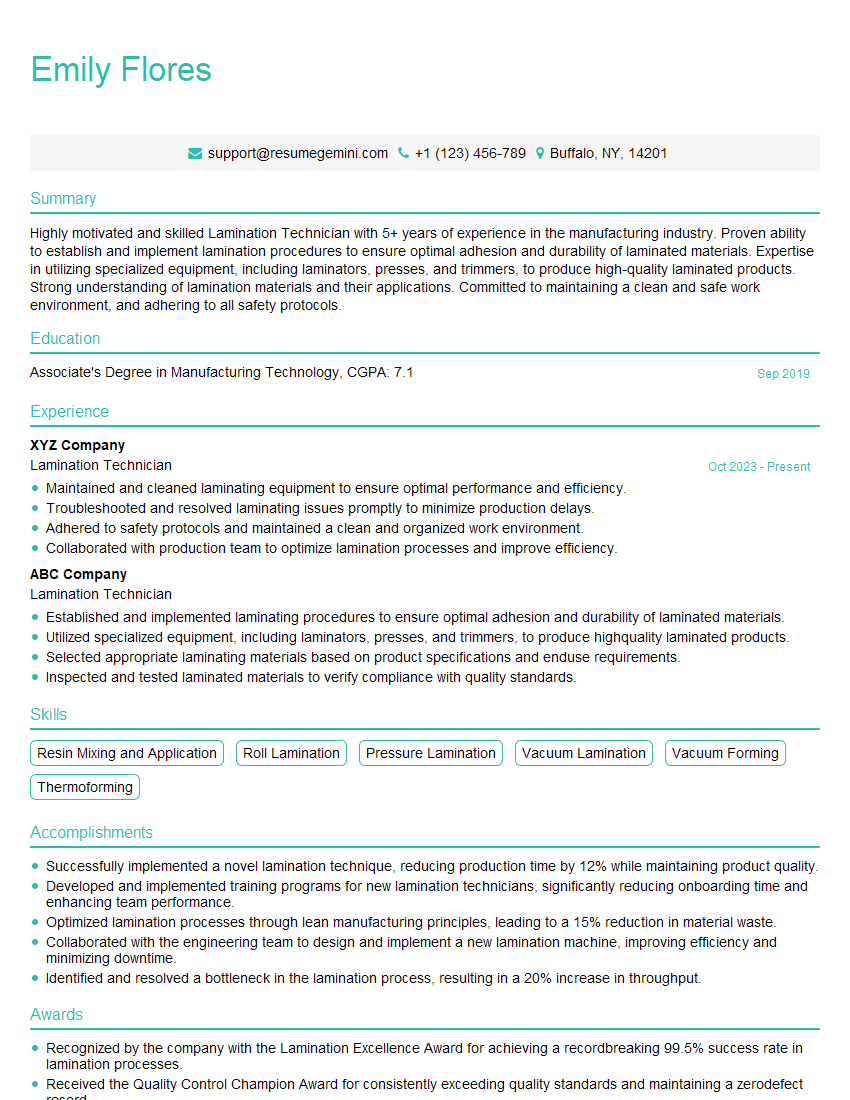

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lamination Technician

1. How would you troubleshoot and repair a lamination machine that is producing defective laminations?

- Check the machine’s temperature settings and adjust them accordingly.

- Inspect the rollers for damage and replace them if necessary.

- Clean the machine’s sensors and ensure they are properly calibrated.

- Check the pressure settings and adjust them to ensure proper bonding.

- Identify any blockages or obstructions and clear them.

- Inspect the laminate material for defects and replace it if necessary.

2. What types of laminating films are available, and what are their respective applications?

Cold laminating films:

- Used for static applications with no heat required.

- Available in various finishes, including matte, glossy, and textured.

Hot laminating films:

- Require heat to activate the adhesive.

- Offer higher durability and resistance to moisture and chemicals.

Liquid laminating films:

- Applied as a liquid that self-levels and forms a protective layer.

- Ideal for irregular surfaces and large-scale applications.

3. How do you ensure the proper tension and alignment of the laminate material during the lamination process?

- Adjust the tension control settings according to the material thickness and type.

- Use alignment guides to align the material with the rollers.

- Inspect the rollers for any uneven wear or damage.

- Calibrate the machine’s sensors to ensure accurate measurements.

4. What are the potential hazards associated with working with lamination machines, and how do you mitigate them?

- Heat burns: Wear heat-resistant gloves and follow safety protocols.

- Cuts from sharp edges: Handle materials carefully and wear safety glasses.

- Chemical exposure: Ensure proper ventilation and use appropriate respiratory protection.

- Noise: Use earplugs or other hearing protection to minimize noise exposure.

- Repetitive motion injuries: Take regular breaks and practice proper ergonomics.

5. How do you calculate the quantity of laminate material required for a specific project?

- Measure the dimensions of the items to be laminated.

- Determine the desired margin around the edges.

- Calculate the total area to be laminated.

- Estimate the waste factor based on the material type and project complexity.

- Multiply the total area by the waste factor to determine the required quantity.

6. What is the difference between pre-masked and post-masked laminating films?

- Pre-masked: Adhesive is protected with a removable liner.

- Post-masked: Adhesive is exposed and requires additional masking before lamination.

7. How do you prepare surfaces for lamination to ensure proper adhesion?

- Clean the surface with a suitable solvent to remove dirt and grease.

- Sand or abrade the surface to create a porous surface.

- Apply a primer or adhesive promoter to enhance bond strength.

- Allow the surface to dry completely before lamination.

8. What is the importance of maintaining proper humidity levels during lamination?

- Controls the rate of adhesive curing.

- Prevents moisture absorption into the laminate or substrate.

- Ensures proper bond strength and durability.

9. How do you monitor and control the quality of laminated products?

- Inspect for defects such as bubbles, creases, and misalignments.

- Test the bond strength using peel or shear testing methods.

- Measure the thickness and dimensions to ensure compliance with specifications.

- Use quality control charts and records to track and monitor quality.

10. What are some new trends and innovations in lamination technology?

- Digital lamination: Allows for variable data and personalized designs.

- Self-healing films: Offer improved durability and resistance to scratches.

- Automated systems: Increase efficiency and reduce labor costs.

- Eco-friendly materials: Focus on reducing environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lamination Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lamination Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lamination Technician plays a pivotal role in the manufacturing process, ensuring the seamless application of laminates to various materials. Their responsibilities encompass a wide range of tasks that contribute to the production of high-quality laminated products.

1. Laminate Preparation

Prior to commencing lamination, the technician meticulously prepares the substrate to ensure optimal adhesion. This involves cleaning, smoothing, and gegebenenfalls applying a primer to the surface.

- Clean and degrease substrates using appropriate solvents and techniques.

- Sand or abrade surfaces to create a smooth and receptive base for lamination.

- Apply primers or adhesives to enhance bonding strength and prevent delamination.

2. Material Handling

The technician is responsible for handling and managing various materials, including laminates, substrates, and adhesives. They must maintain a clean and organized work area to prevent contamination and ensure safety.

- Unload and inspect laminates and substrates to verify their quality and dimensions.

- Accurately measure and cut laminates to the desired size and shape.

- Prepare and mix adhesives according to specified ratios and application methods.

3. Lamination Process

The core responsibility of a Lamination Technician lies in executing the lamination process with precision and efficiency. They operate specialized machinery to apply laminates to substrates, ensuring proper alignment, pressure, and temperature control.

- Load substrates and laminates into laminating machines and set appropriate parameters.

- Monitor pressure, temperature, and dwell time to achieve optimal bonding.

- Inspect laminated products for defects and ensure they meet quality standards.

4. Finishing and Maintenance

Once the lamination process is complete, the technician performs finishing operations to enhance the product’s appearance and durability. They also maintain equipment and ensure a safe and efficient work environment.

- Trim excess laminates and remove any burrs or imperfections.

- Apply protective coatings or sealants to improve resistance to wear and tear.

- Clean and maintain laminating machines and tools to ensure optimal performance.

Interview Tips

To excel in a Lamination Technician interview, candidates should prepare thoroughly and demonstrate a comprehensive understanding of the role and their own capabilities. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company’s products, services, and industry. Familiarize yourself with the specific requirements of the Lamination Technician role and identify how your skills and experience align with them.

- Visit the company’s website to learn about their business, values, and recent developments.

- Read industry publications and articles to stay abreast of current trends and technologies.

- Prepare questions about the company, the position, and the team you would be joining.

2. Showcase Your Technical Skills and Experience

Highlight your proficiency in lamination techniques, machinery operation, and material handling. Describe specific projects or accomplishments that demonstrate your ability to achieve high-quality results. If you have experience with different types of laminates or substrates, be sure to mention it.

- Provide specific examples of how you have ensured precision and accuracy in your work.

- Discuss your experience with quality control procedures and your commitment to maintaining high standards.

- Emphasize your ability to troubleshoot problems and find solutions.

3. Emphasize Safety and Attention to Detail

Laminating involves working with potentially hazardous materials and equipment. Demonstrate your awareness of safety protocols and your commitment to maintaining a safe and clean work environment. Highlight your attention to detail and your ability to follow instructions carefully.

- Describe your understanding of the importance of safety regulations and your experience in adhering to them.

- Provide examples of how you have identified and mitigated potential hazards in the workplace.

- Explain how your meticulous nature ensures that you pay close attention to details and produce high-quality work.

4. Be Prepared to Discuss Your Work Style and Teamwork Skills

Lamination Technicians often work as part of a team, so it’s essential to demonstrate your ability to collaborate effectively. Be prepared to discuss your communication skills, your ability to work independently, and your willingness to contribute to the team’s success.

- Provide examples of how you have worked effectively in a team environment.

- Explain how you resolve conflicts or disagreements with colleagues.

- Discuss your ability to meet deadlines and manage multiple priorities.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lamination Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.