Are you gearing up for a career in Lap Grinder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lap Grinder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

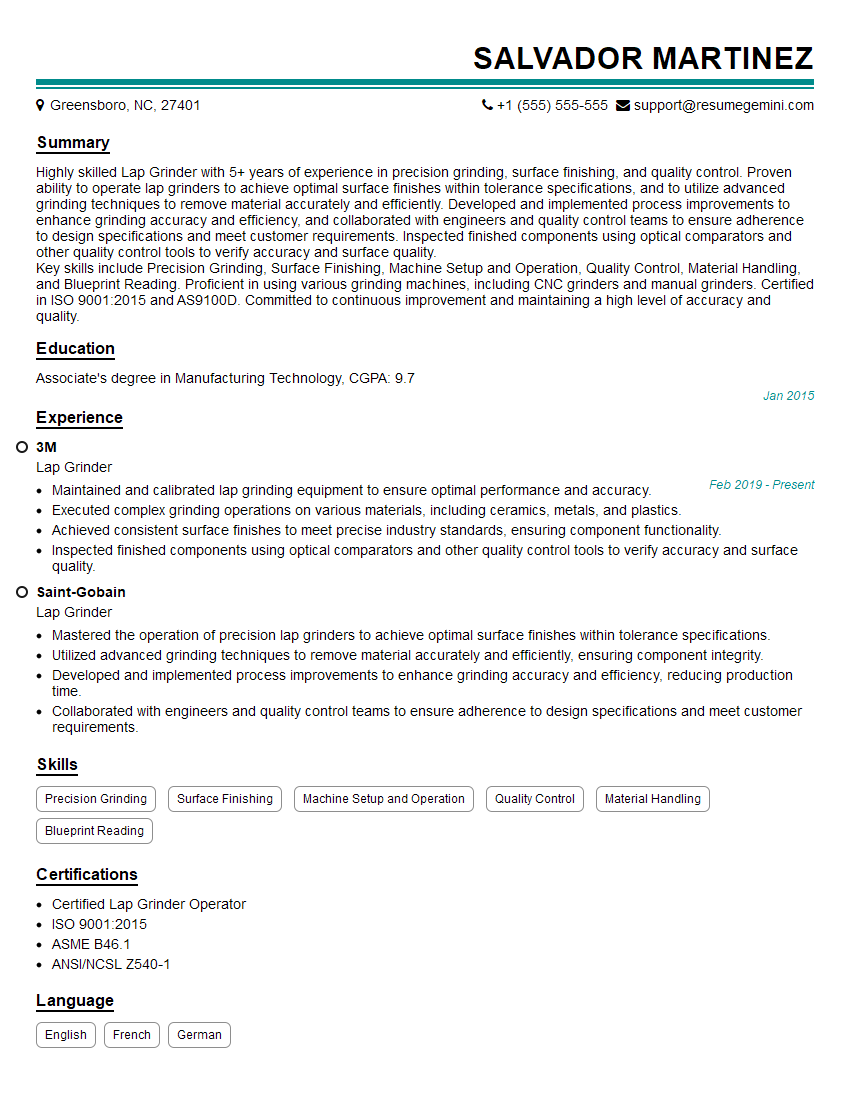

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lap Grinder

1. What are the different types of lap grinding machines?

There are three main types of lap grinding machines: horizontal spindle, vertical spindle, and CNC lap grinding machines.

- Horizontal spindle lap grinding machines are the most common type. They are used for grinding flat surfaces, such as those found on engine blocks and cylinder heads.

- Vertical spindle lap grinding machines are used for grinding cylindrical surfaces, such as those found on shafts and bearings.

- CNC lap grinding machines are computer-controlled machines that can be used to grind complex shapes.

2. What are the different types of laps used in lap grinding?

There are two main types of laps used in lap grinding: metal laps and diamond laps.

Metal laps

- Metal laps are made of cast iron or steel.

- They are used for grinding hard materials, such as steel and carbide.

- Metal laps are less expensive than diamond laps.

Diamond laps

- Diamond laps are made of a metal matrix that is impregnated with diamond particles.

- They are used for grinding soft materials, such as glass and ceramics.

- Diamond laps are more expensive than metal laps.

3. What are the advantages of lap grinding?

Lap grinding offers a number of advantages over other grinding processes, including:

- High precision: Lap grinding can produce parts with very high precision, making it ideal for applications where close tolerances are required.

- Good surface finish: Lap grinding can produce a very good surface finish, making it ideal for parts that need to be smooth and free of burrs.

- Low heat generation: Lap grinding generates very little heat, which can help to prevent damage to the workpiece.

- Versatility: Lap grinding can be used to grind a wide variety of materials, including metals, ceramics, and glass.

4. What are the disadvantages of lap grinding?

Lap grinding also has some disadvantages, including:

- Slow process: Lap grinding is a relatively slow process, which can make it less efficient for high-volume applications.

- High cost: Lap grinding machines and laps can be expensive, which can make it a less cost-effective option for some applications.

- Limited depth of cut: Lap grinding can only remove a limited amount of material in each pass, which can make it difficult to grind deep or complex shapes.

5. What are the applications of lap grinding?

Lap grinding is used in a wide variety of applications, including:

- Automotive: Lap grinding is used to grind engine blocks, cylinder heads, and other automotive components.

- Aerospace: Lap grinding is used to grind aircraft engine components, such as turbine blades and compressor blades.

- Medical: Lap grinding is used to grind surgical implants and other medical devices.

- Electronics: Lap grinding is used to grind semiconductor wafers and other electronic components.

6. What are the safety precautions that must be taken when operating a lap grinding machine?

When operating a lap grinding machine, it is important to take a number of safety precautions, including:

- Wear eye protection, such as goggles or a face shield.

- Wear ear protection, such as earplugs or ear muffs.

- Wear gloves to protect your hands from the sharp edges of the lap and the workpiece.

- Make sure the machine is properly guarded to prevent contact with the grinding wheel.

- Do not operate the machine if you are tired or under the influence of alcohol or drugs.

7. How do you maintain a lap grinding machine?

To maintain a lap grinding machine, it is important to:

- Clean the machine regularly to remove dust and debris.

- Inspect the lap and the grinding wheel regularly for wear or damage.

- Lubricate the machine regularly according to the manufacturer’s instructions.

- Have the machine serviced by a qualified technician on a regular basis.

8. What are the different types of coolants used in lap grinding?

The three most common types of coolants used in lap grinding are:

- Water: Water is the most common coolant used in lap grinding. It is inexpensive and readily available.

- Oil: Oil is a good coolant for grinding hard materials, such as steel and carbide. It helps to reduce friction and heat generation.

- Synthetic coolants: Synthetic coolants are designed to provide better cooling and lubrication than water or oil. They are typically more expensive than water or oil, but they can offer significant benefits in terms of performance and tool life.

9. What are the different types of abrasives used in lap grinding?

The two most common types of abrasives used in lap grinding are:

- Diamond: Diamond is the hardest material known to man. It is used for grinding hard materials, such as steel and carbide.

- CBN: CBN (cubic boron nitride) is a synthetic abrasive that is second only to diamond in terms of hardness. It is used for grinding hard materials, such as steel and ceramics.

10. What are the different types of workholding devices used in lap grinding?

The three most common types of workholding devices used in lap grinding are:

- Magnetic chucks: Magnetic chucks are used to hold ferrous workpieces in place. They are strong and easy to use.

- Vacuum chucks: Vacuum chucks are used to hold non-ferrous workpieces in place. They are less powerful than magnetic chucks, but they can be used to hold workpieces of any shape.

- Fixture plates: Fixture plates are used to hold workpieces in place using clamps or bolts. They are the most versatile type of workholding device, but they can be more time-consuming to use than magnetic or vacuum chucks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lap Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lap Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lap Grinders are skilled professionals responsible for operating and maintaining lapping machines to grind and polish surfaces to precise dimensions. They play a crucial role in manufacturing processes that demand high levels of precision and surface quality.

1. Machine Operation and Setup

Set up and operate lapping machines according to specifications, ensuring proper alignment and calibration.

- Select and install appropriate grinding wheels, diamond laps, and other tooling.

- Adjust machine parameters such as speed, pressure, and coolant flow.

2. Material Preparation and Grinding

Prepare materials for grinding, including cleaning, masking, and mounting.

- Operate lapping machines to grind and polish materials to specified dimensions and surface finishes.

- Monitor grinding progress and make adjustments as needed to achieve desired results.

3. Quality Assurance and Inspection

Inspect finished parts using precision measuring tools and gauges to ensure accuracy and compliance with specifications.

- Identify and correct any defects or deviations from specifications.

- Maintain detailed records of grinding parameters and inspection results.

4. Machine Maintenance and Troubleshooting

Perform regular maintenance tasks on lapping machines to ensure optimal performance.

- Troubleshoot and resolve machine issues promptly to minimize downtime.

- Maintain a clean and organized work area.

Interview Tips

Preparing thoroughly for a Lap Grinder interview is essential to showcase your skills and experience effectively. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s profile, industry, and culture. Research the specific job responsibilities and requirements.

- Visit the company’s website and social media pages.

- Look for news articles and industry publications about the company.

2. Practice Your Answers

Anticipate potential interview questions and prepare well-structured answers that highlight your relevant skills and experience.

- Use the STAR method (Situation, Task, Action, Result) to frame your answers.

- Quantify your accomplishments with specific metrics and examples.

3. Showcase Your Technical Expertise

Emphasize your knowledge of lapping machines, grinding techniques, and quality control procedures.

- Discuss your experience with different types of materials and grinding challenges.

- Highlight any certifications or training you have in lapping operations.

4. Demonstrate Your Problem-Solving Abilities

Share examples of how you have successfully resolved machine breakdowns or production issues.

- Describe your analytical approach to identifying and solving problems.

- Emphasize your ability to work under pressure and manage deadlines effectively.

5. Be Enthusiastic and Professional

Convey your passion for precision grinding and your commitment to delivering high-quality results.

- Maintain a positive and enthusiastic demeanor throughout the interview.

- Dress professionally and arrive punctually.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lap Grinder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!