Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lap Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

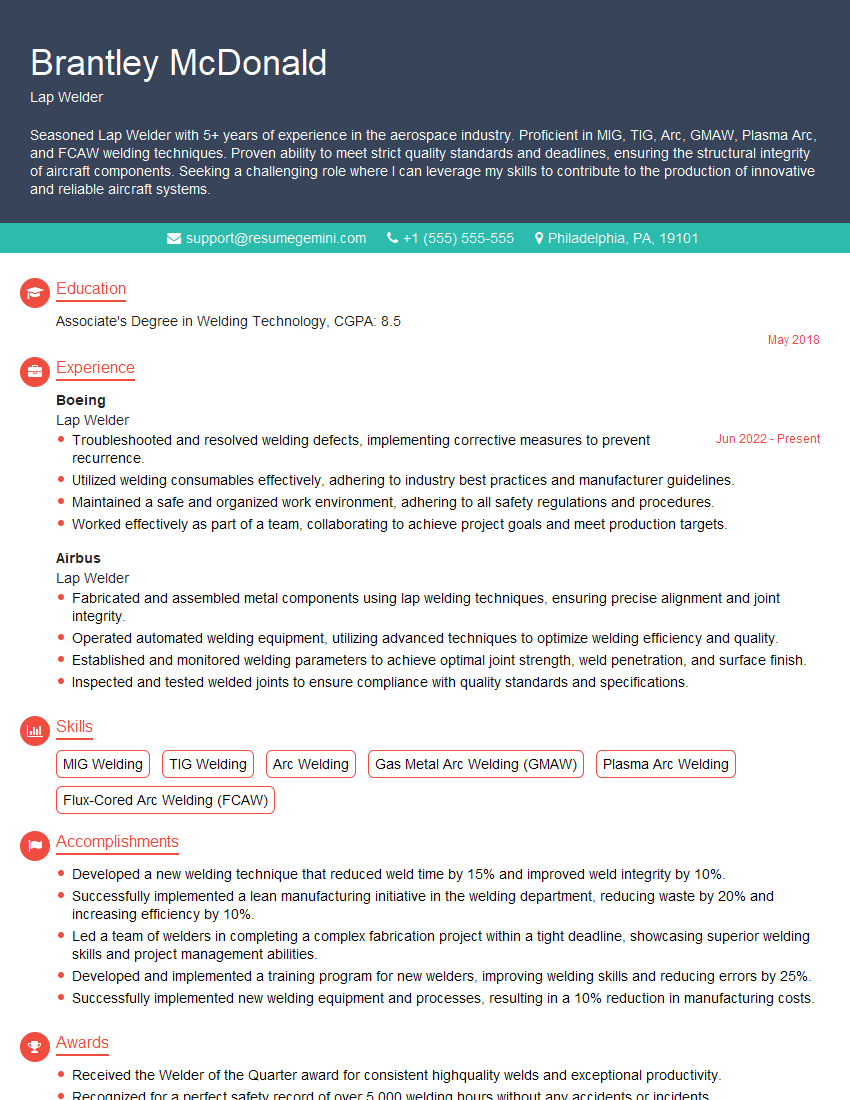

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lap Welder

1. Describe the different types of lap welding processes you are familiar with?

There are several types of lap welding processes, including:

- Resistance Lap Welding

- Laser Lap Welding

- Electron Beam Lap Welding

- Ultrasonic Lap Welding

- Friction Lap Welding

2. What are the key factors that affect the quality of a lap weld?

Material Thickness

- The thickness of the materials being welded

- The thicker the materials, the more difficult it is to achieve a good weld.

Material Properties

- The properties of the materials being welded

- Some materials are more difficult to weld than others.

Welding Parameters

- The welding parameters, such as the welding speed, the welding current, and the welding pressure

- These parameters must be carefully controlled to achieve a good weld.

3. What are the common defects that can occur in lap welds?

The most common defects that can occur in lap welds include:

- Lack of fusion

- Porosity

- Cracking

- Warping

- Discoloration

4. What are the different methods for inspecting lap welds?

The most common methods for inspecting lap welds include:

- Visual inspection

- Radiography

- Ultrasonic testing

- Dye penetrant testing

- Magnetic particle testing

5. What are the safety precautions that should be taken when lap welding?

The most important safety precautions that should be taken when lap welding include:

- Wear proper protective clothing, including gloves, eye protection, and a welding helmet.

- Ensure that the welding area is well-ventilated.

- Do not weld in the presence of flammable materials.

- Follow all manufacturer’s instructions for the welding equipment.

6. How do you set up a lap welding machine?

The steps for setting up a lap welding machine can vary depending on the type of machine. However, the general steps include:

- Mount the welding head on the machine.

- Set the welding parameters, such as the welding speed, the welding current, and the welding pressure.

- Load the materials to be welded into the machine.

- Start the welding process.

7. How do you troubleshoot a lap welding machine?

The steps for troubleshooting a lap welding machine can vary depending on the type of machine. However, the general steps include:

- Check the power supply.

- Check the welding head.

- Check the welding parameters.

- Check the materials being welded.

8. What are the advantages of lap welding?

The advantages of lap welding include:

- High strength

- Good electrical conductivity

- Low cost

- Easy to automate

9. What are the disadvantages of lap welding?

The disadvantages of lap welding include:

- Not suitable for all materials

- Can be difficult to achieve a good weld on thick materials

- Can be difficult to inspect

10. What are the applications of lap welding?

Lap welding is used in a wide variety of applications, including:

- Automotive

- Aerospace

- Electronics

- Construction

- Medical

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lap Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lap Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lap Welders are responsible for joining metal surfaces together using a specialized welding technique. Their primary duties include:

1. Welding Setup

Setting up and maintaining welding equipment, including torches, power supplies, and welding rods.

- Ensuring proper equipment calibration and operation.

- Selecting appropriate welding materials and parameters based on the job requirements.

2. Welding Execution

Performing lap welds on various metal surfaces using a variety of welding techniques.

- Following detailed welding specifications and blueprints.

- Monitoring weld quality and ensuring that welds meet industry standards.

3. Post-Welding Inspection

Inspecting welds for flaws and defects, such as cracks, porosity, and inclusions.

- Using visual, non-destructive testing methods to assess weld quality.

- Reporting any welding issues or defects to supervisors.

4. Maintenance and Safety

Maintaining a clean and organized work area, as well as properly storing welding materials.

- Adhering to all safety regulations and protocols.

- Wearing appropriate personal protective equipment (PPE).

Interview Tips

To ace the interview for a Lap Welder position, it is crucial to prepare thoroughly and demonstrate your skills and qualifications. Here are some interview tips and hacks:

1. Research the Company and Role

Gather information about the company’s industry, products/services, and culture. Learn about the specific role and its responsibilities.

- Visit the company’s website and social media pages.

- Read industry articles and news about the company.

2. Practice Your Welding Skills

Before the interview, practice your welding techniques to ensure proficiency.

- Set up a welding station in a safe location.

- Practice welding different metal types and thicknesses.

3. Highlight Your Experience and Qualifications

During the interview, emphasize your welding experience and any certifications or training you have obtained.

- Provide specific examples of welding projects you have completed.

- Quantify your accomplishments to demonstrate your impact.

4. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer. This shows your interest in the role and the company.

- Ask about the company’s safety protocols.

- Inquire about opportunities for professional development.

5. Dress Professionally and Be Punctual

First impressions matter. Present yourself in a professional manner and arrive on time for the interview.

- Wear clean and appropriate clothing.

- Bring a portfolio or examples of your previous work.

Next Step:

Now that you’re armed with the knowledge of Lap Welder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lap Welder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini