Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lapper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lapper so you can tailor your answers to impress potential employers.

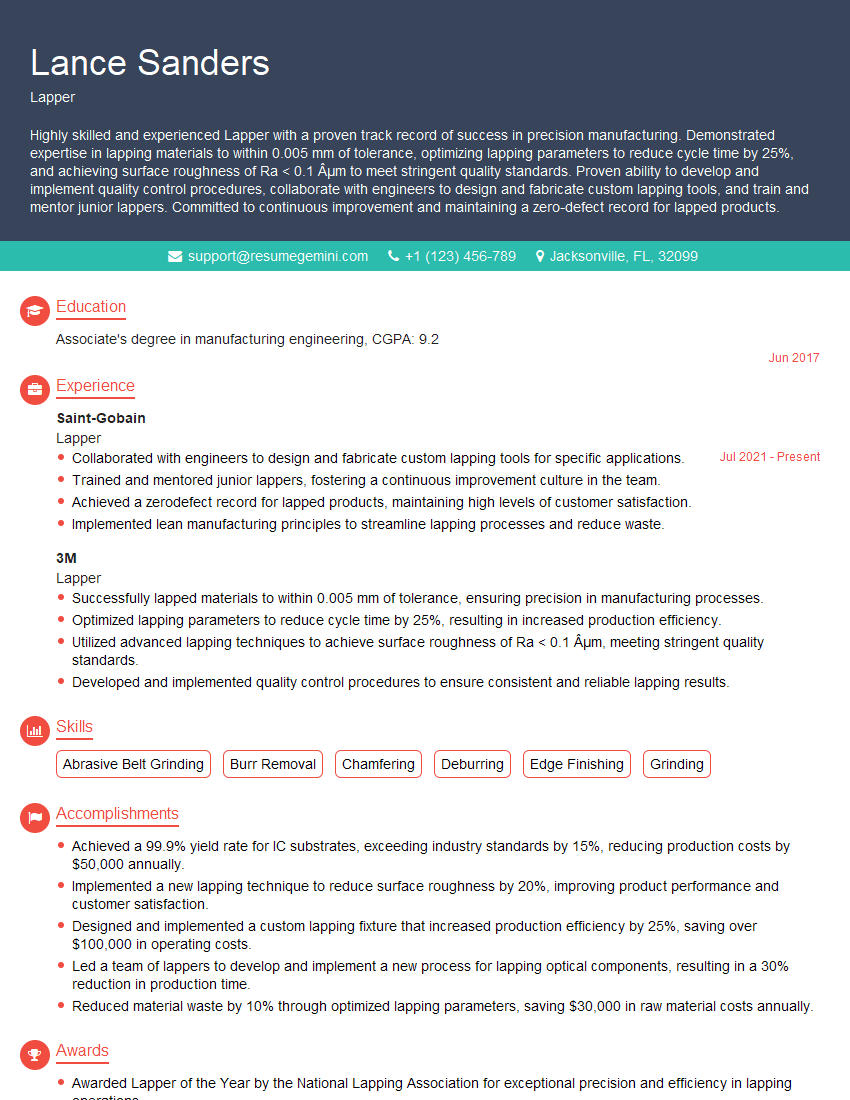

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lapper

1. How do you ensure that a lapper is properly aligned before use?

- Inspect the lapping plate for any debris or damage.

- Place the lapping plate on a flat surface.

- Use a level or straightedge to check the flatness of the lapping plate.

- Adjust the leveling screws on the lapping machine until the lapping plate is level.

- Use a dial indicator to check the alignment of the lapping plate to the spindle.

- Adjust the alignment screws on the lapping machine until the lapping plate is aligned with the spindle.

2. What are the different types of lapping abrasives and their applications?

- Loose abrasives are used for general-purpose lapping and can be made from a variety of materials such as aluminum oxide, silicon carbide, and diamond.

- Bonded abrasives are used for more precise lapping and are made from a mixture of abrasive particles and a bonding agent such as resin or metal.

- Diamond abrasives are used for lapping hard materials such as glass and ceramics.

3. How do you select the correct grit size for a lapping operation?

The grit size of the lapping abrasive should be selected based on the material being lapped and the desired surface finish. For example, a coarser grit size will be used for removing large amounts of material, while a finer grit size will be used for producing a smoother surface finish.

4. What are the different types of lapping fluids and their applications?

- Water-based lapping fluids are used for general-purpose lapping and are typically made from a mixture of water and a surfactant.

- Oil-based lapping fluids are used for lapping hard materials such as glass and ceramics and are typically made from a mixture of oil and a surfactant.

- Synthetic lapping fluids are used for lapping exotic materials such as beryllium and are typically made from a mixture of synthetic oils and surfactants.

5. How do you control the lapping pressure and speed?

- The lapping pressure is controlled by adjusting the force applied to the lapping plate.

- The lapping speed is controlled by adjusting the speed of the lapping plate.

6. How do you monitor the progress of a lapping operation?

- The progress of a lapping operation can be monitored by measuring the thickness of the material being lapped.

- The surface finish of the material being lapped can be monitored by using a surface profiler.

7. How do you troubleshoot common lapping problems?

- If the lapping process is not removing material, the lapping abrasive may be too coarse or the lapping pressure may be too low.

- If the lapping process is producing a rough surface finish, the lapping abrasive may be too coarse or the lapping speed may be too high.

- If the lapping process is causing the material being lapped to warp, the lapping pressure may be too high.

8. What are the safety precautions that must be taken when operating a lapping machine?

- Always wear safety glasses when operating a lapping machine.

- Always wear gloves when handling lapping abrasives.

- Never operate a lapping machine without proper guarding.

- Never leave a lapping machine unattended while it is running.

9. What are the different types of lapping machines?

- Vertical lapping machines are used for lapping flat surfaces.

- Horizontal lapping machines are used for lapping cylindrical surfaces.

- Automatic lapping machines are used for high-volume lapping operations.

10. What are the applications of lapping?

- Lapping is used to produce precision surfaces on a variety of materials, including metals, glass, and ceramics.

- Lapping is used to remove burrs and sharp edges from parts.

- Lapping is used to polish surfaces to a high degree of finish.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lapper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lapper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lappers are responsible for the precision grinding and lapping of optical components. They work with a variety of materials, including glass, quartz, fused silica, and sapphire. Lappers use a variety of tools and equipment, including grinding wheels, lapping plates, and polishing compounds. They must have a strong understanding of the principles of optics and be able to work with precision instruments.

1. Grinding and polishing optical components

Lappers use grinding wheels and lapping plates to remove material from optical components. They must be able to control the amount of material removed and the surface finish of the component. Lappers also use polishing compounds to improve the surface finish of optical components.

2. Inspecting optical components

Lappers are responsible for inspecting optical components to ensure that they meet the required specifications. They use a variety of tools and equipment, including microscopes, interferometers, and profilometers.

3. Maintaining equipment

Lappers are responsible for maintaining the equipment they use. They must be able to troubleshoot and repair problems with grinding wheels, lapping plates, and polishing compounds.

4. Working with other team members

Lappers often work with other team members, including engineers, scientists, and technicians. They must be able to communicate effectively with others and work as part of a team.

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Before you go to an interview, it’s important to do your research. This means learning about the company’s history, culture, and products. You should also read the job description carefully and make sure you understand the qualifications and requirements for the position.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure your clothes are clean and wrinkle-free.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you’re running late, call the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself during your interview. Don’t try to be someone you’re not, because the interviewer will be able to tell. Just relax, be confident, and let your personality shine through.

Next Step:

Now that you’re armed with the knowledge of Lapper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lapper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini