Feeling lost in a sea of interview questions? Landed that dream interview for Lapping Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lapping Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

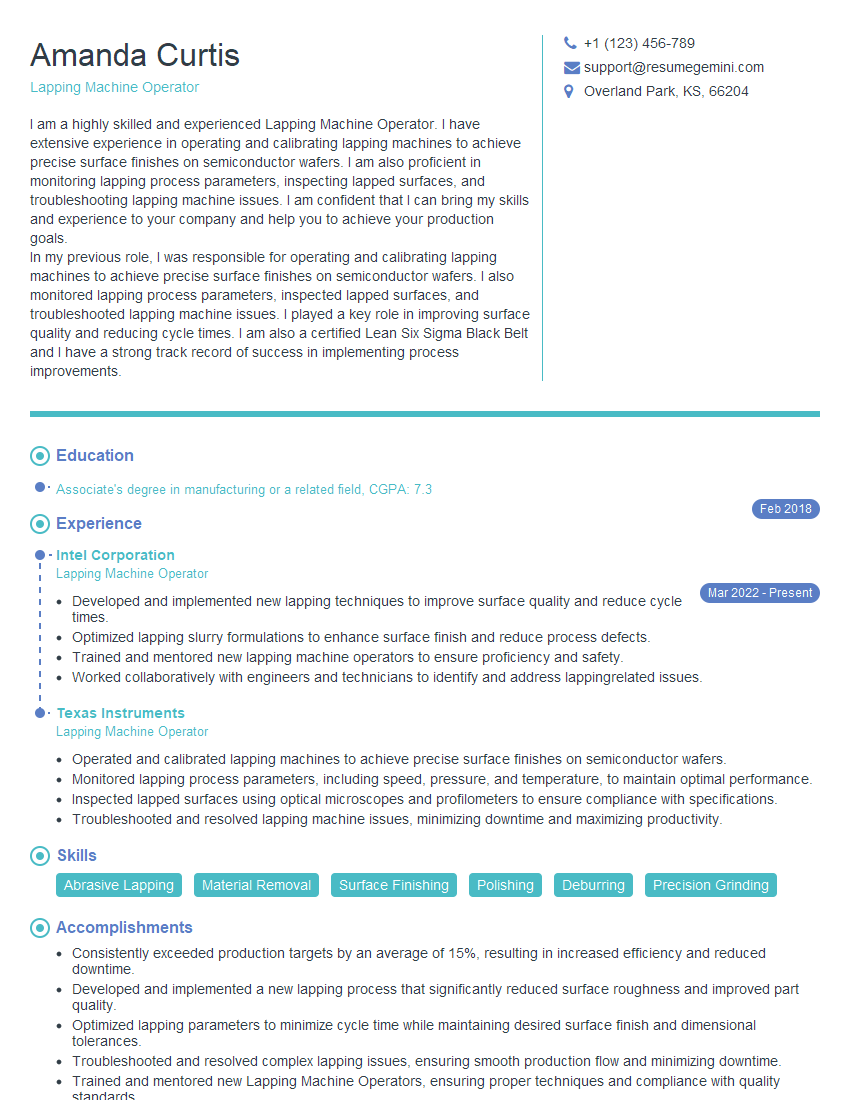

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lapping Machine Operator

1. What is the purpose of lapping?

Lapping is a precision abrasive machining process that removes material from a surface to achieve high dimensional accuracy and surface finish.

2. What are the different types of lapping machines?

- Rotary lapping machines

- Flat lapping machines

- Cylindrical lapping machines

3. What are the main components of a lapping machine?

- Workpiece holder

- Lapping plate

- Abrasive slurry

- Lubricant

4. What are the different types of abrasive slurry used in lapping?

- Water-based slurries

- Oil-based slurries

- Solid-phase slurries

5. What are the factors that affect the surface finish in lapping?

- Abrasive grain size

- Abrasive concentration

- Lapping pressure

- Lapping speed

- Lapping time

6. What are the advantages of lapping over other machining processes?

- High precision and accuracy

- Excellent surface finish

- Reduced material waste

7. What are the challenges associated with lapping?

- Time-consuming process

- Requires skilled operators

- Can be expensive

8. What are the different industries that use lapping?

- Automotive

- Aerospace

- Electronics

- Optics

9. What are the safety precautions to be taken when operating a lapping machine?

- Wear proper safety gear

- Keep work area clean

- Ensure proper ventilation

- Follow machine manufacturer’s instructions

10. What are your strengths and weaknesses as a lapping machine operator?

Strengths:

- Excellent attention to detail

- Proven ability to operate lapping machines

- Knowledge of different types of lapping processes

Weaknesses:

- Lack of experience in operating large-scale lapping machines

- Need to improve time management skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lapping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lapping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lapping Machine Operators are highly skilled individuals responsible for operating and maintaining lapping machines utilized in various manufacturing processes. They are tasked with ensuring the precision and accuracy of lapped components, adhering to established quality standards and specifications.

1. Machine Operation

Primary responsibility is operating lapping machines to achieve specified surface finishes and tolerances on workpieces.

- Follow established procedures and adjust machine settings for optimal performance.

- Monitor machine performance, identify issues, and make necessary adjustments to ensure smooth operation.

2. Workpiece Handling

Proper handling of workpieces throughout the lapping process is crucial.

- Inspect workpieces prior to lapping to identify potential defects or inconsistencies.

- Secure workpieces on lapping plates or fixtures to ensure stability during the process.

- Maintain a clean and organized work area to prevent contamination and ensure accuracy.

3. Abrasive Selection and Application

Choosing the appropriate abrasive for the specific material and desired surface finish is essential.

- Identify the correct abrasive type, grain size, and concentration for each lapping application.

- Apply abrasives evenly to lapping plates or use automatic abrasive feeders to ensure consistent surface finish.

4. Quality Control

Inspecting and measuring workpieces throughout the lapping process ensures adherence to specifications.

- Perform dimensional measurements using precision instruments (e.g., micrometers, calipers) to verify workpiece dimensions.

- Examine surface finish under magnification to ensure it meets the desired roughness or smoothness.

5. Machine Maintenance

Regularly maintain and troubleshoot lapping machines to prevent breakdowns and ensure optimal performance.

- Clean and lubricate machine components as per manufacturer’s recommendations.

- Identify and replace worn parts or components to maintain accuracy and prevent costly downtime.

Interview Tips

Preparing thoroughly for an interview is essential to showcase your skills and qualifications as a Lapping Machine Operator. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific requirements of the Lapping Machine Operator position.

- Visit the company website and social media pages to gather information.

- Review the job description carefully to identify key responsibilities and qualifications.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that highlight your relevant skills and experience.

- Prepare examples of your experience in operating and maintaining lapping machines.

- Practice answering questions related to abrasive selection, workpiece handling, and quality control procedures.

3. Quantify Your Accomplishments

Use specific numbers and metrics to demonstrate your contributions and achievements as a Lapping Machine Operator.

- Provide examples of how you improved efficiency or reduced downtime through effective machine maintenance.

- Quantify your success in meeting or exceeding quality standards for lapped components.

4. Show Enthusiasm and Passion

Conveying your genuine interest in the role and the company can make a positive impression on the interviewer.

- Express your passion for precision manufacturing and your desire to contribute to the team’s success.

- Ask thoughtful questions about the company’s commitment to quality and innovation.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive at the interview on time. Maintain a positive and confident attitude throughout the interview.

- Choose appropriate attire that aligns with the company’s dress code.

- Punctuality demonstrates respect for the interviewer’s time and professionalism.

Next Step:

Now that you’re armed with the knowledge of Lapping Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lapping Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini