Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lapping Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lapping Machine Tender so you can tailor your answers to impress potential employers.

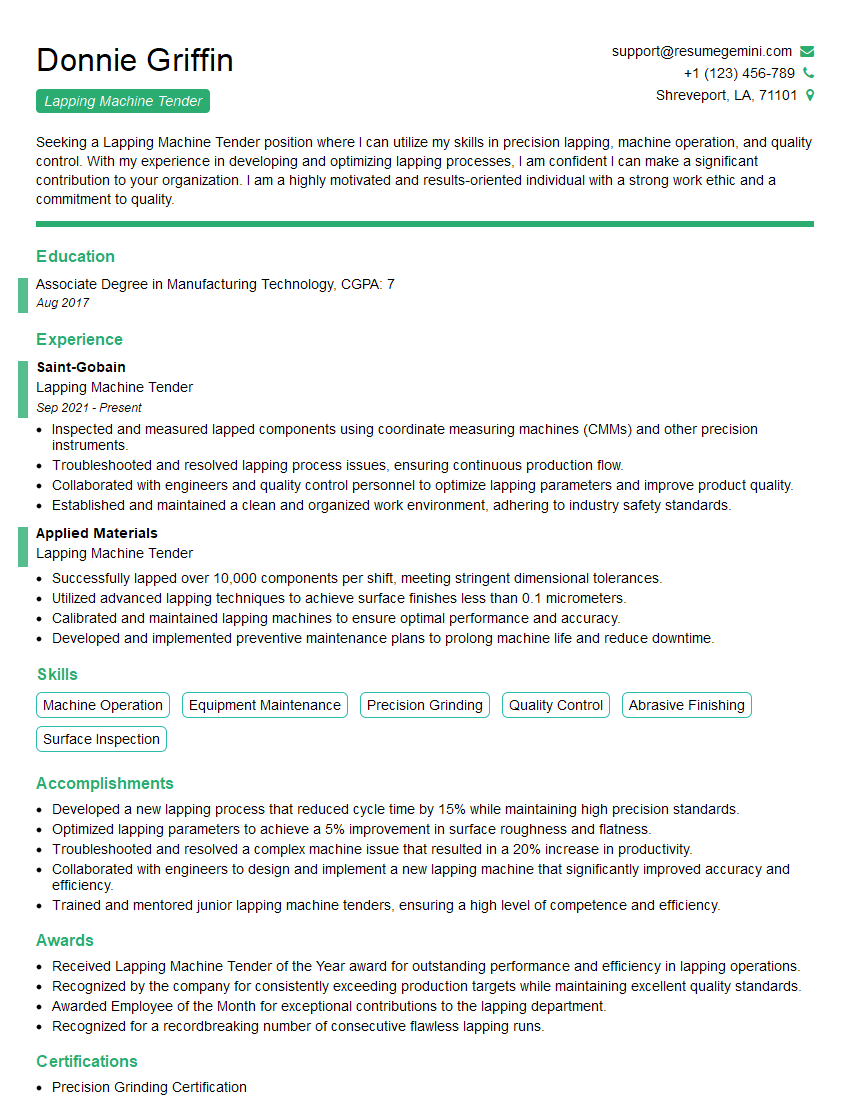

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lapping Machine Tender

1. Explain the process of lapping a surface?

Lapping is a machining process that uses a loose abrasive suspended in a liquid to remove material from a surface. The abrasive particles roll between the workpiece and a lap, which is a flat or curved surface made of a hard material such as cast iron, steel, or diamond. The workpiece is held against the lap and moved in a circular or back-and-forth motion. The abrasive particles cut into the workpiece, removing material and creating a smooth, flat surface.

2. What are the different types of lapping machines?

Horizontal lapping machines

- The workpiece is held horizontally and moved back and forth across the lap.

- Used for lapping flat surfaces.

Vertical lapping machines

- The workpiece is held vertically and moved up and down across the lap.

- Used for lapping cylindrical surfaces.

Rotary lapping machines

- The workpiece is held in a chuck and rotated against the lap.

- Used for lapping both flat and cylindrical surfaces.

3. What are the key factors that affect the quality of a lapped surface?

- The type of abrasive

- The size of the abrasive particles

- The concentration of the abrasive in the liquid

- The speed of the lapping machine

- The pressure applied to the workpiece

- The duration of the lapping process

4. What are the common problems that can occur during lapping?

- Scratches

- Gouges

- Burnishing

- Warping

- Cracking

5. How can these problems be prevented?

- Scratches can be prevented by using a fine abrasive and applying light pressure.

- Gouges can be prevented by using a coarser abrasive and applying more pressure.

- Burnishing can be prevented by using a lubricant and lapping for a shorter period of time.

- Warping can be prevented by using a lap that is flat and parallel to the workpiece.

- Cracking can be prevented by using a lap that is not too hard.

6. What are the different types of abrasives used in lapping?

- Aluminum oxide

- Silicon carbide

- Boron carbide

- Diamond

- Cubic boron nitride

7. How do you select the right abrasive for a particular lapping job?

- The type of material being lapped

- The desired surface finish

- The speed of the lapping machine

- The pressure applied to the workpiece

- The duration of the lapping process

8. What are the safety precautions that must be taken when operating a lapping machine?

- Wear eye protection.

- Wear gloves.

- Use a dust mask.

- Keep the work area clean and free of debris.

- Follow the manufacturer’s instructions for operating the machine.

9. What are the maintenance procedures that must be performed on a lapping machine?

- Clean the machine regularly.

- Lubricate the machine regularly.

- Inspect the machine regularly for wear and tear.

- Replace worn parts as necessary.

10. What are the troubleshooting procedures for a lapping machine?

- If the machine is not cutting, check the abrasive and the pressure being applied to the workpiece.

- If the machine is making a lot of noise, check the bearings and the gears.

- If the machine is vibrating, check the balance of the workpiece.

- If the machine is leaking, check the seals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lapping Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lapping Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lapping Machine Tenders are responsible for operating and maintaining lapping machines, which are used to polish and finish surfaces of various products, including optical lenses, semiconductor wafers, and metal components.

1. Machine Operation

Operate lapping machines according to established procedures and specifications.

- Load and unload materials onto the machine.

- Adjust machine settings, such as speed, pressure, and coolant flow.

2. Quality Control

Inspect finished products to ensure they meet required specifications.

- Monitor machine performance and make adjustments as needed.

- Identify and correct any defects in the lapping process.

3. Maintenance and Repair

Perform routine maintenance on lapping machines.

- Clean and lubricate machines.

- Replace worn or damaged parts.

4. Safety and Compliance

Follow safety regulations and procedures.

- Wear appropriate safety gear, such as gloves and safety glasses.

- Maintain a clean and organized work area.

Interview Tips

Preparing for a Lapping Machine Tender interview requires a combination of technical knowledge and a strong understanding of the industry. Here are some tips to help you ace the interview and land the job.

1. Research the Company and Role

Before the interview, thoroughly research the company and the specific role you are applying for. Visit the company’s website, LinkedIn page, and Glassdoor reviews to learn about their culture, products, and values. This will help you tailor your answers to align with the company’s needs and goals.

2. Highlight Relevant Experience

In your resume and interview, emphasize any previous experience operating or maintaining lapping machines or similar equipment. Quantify your accomplishments whenever possible using specific numbers or metrics. For example, instead of saying “I operated a lapping machine,” say “I operated a lapping machine for six years, producing over 1,000 polished lenses per month.”

3. Demonstrate Quality Control Expertise

Quality control is a crucial aspect of lapping, so be prepared to discuss your experience in this area. Explain the quality control procedures you have followed in previous roles and how you ensured that finished products met specifications.

4. Showcase Problem-Solving Skills

Lapping Machine Tenders often encounter problems with machines or materials. In the interview, provide examples of how you have identified and resolved issues. Highlight your ability to think critically, troubleshoot problems, and make informed decisions.

5. Emphasize Safety and Compliance

Safety is paramount in manufacturing environments. In the interview, emphasize your commitment to safety and compliance. Explain your understanding of safety regulations and how you maintain a safe work area.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lapping Machine Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.