Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Large Sheetfed Press Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Large Sheetfed Press Operator so you can tailor your answers to impress potential employers.

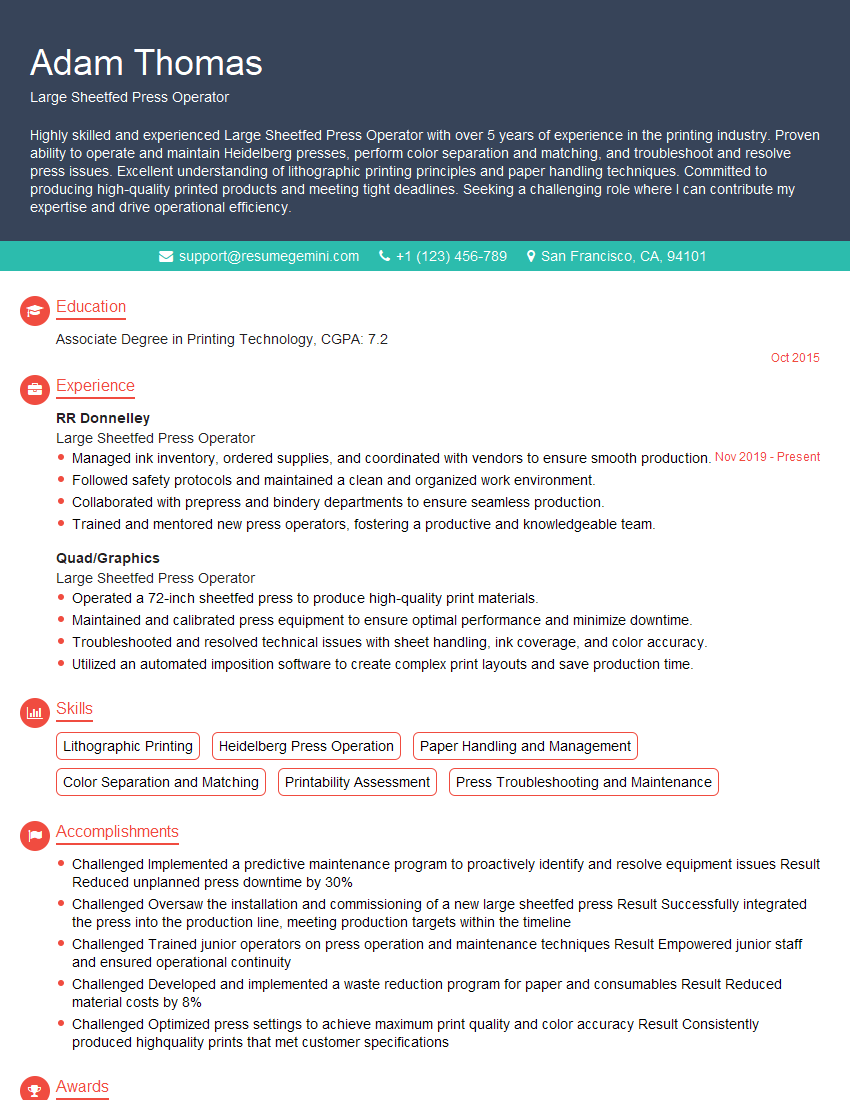

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Large Sheetfed Press Operator

1. What are the key responsibilities of a Large Sheetfed Press Operator?

- Set up and operate large sheetfed printing presses.

- Load paper and ink into the press.

- Adjust press settings to ensure optimal print quality.

- Monitor the press during operation and make adjustments as needed.

- Inspect printed products and ensure they meet quality standards.

2. What are the different types of printing presses you have experience operating?

Offset Printing Presses

- Heidelberg Speedmaster

- Komori Lithrone

Digital Printing Presses

- HP Indigo

- Xerox iGen

3. What is the difference between offset and digital printing?

- Offset printing uses metal plates to transfer ink to paper, while digital printing uses a direct digital-to-press process.

- Offset printing is better for long runs and high-quality printing, while digital printing is more cost-effective for short runs and variable data printing.

4. What are the different paper types and weights that you can print on?

- Uncoated

- Coated

- Offset

- Newsprint

- Cardstock

- Paper weights range from 60# to 120# for offset printing and 100# to 300# for digital printing.

5. What is the importance of color calibration in printing?

- Color calibration ensures that printed colors match the intended colors on screen.

- It is important for accurate color reproduction and consistent print quality.

6. What are the common printing defects and how do you prevent them?

- Ghosting (double imaging) – caused by incorrect press settings or poor registration

- Streaking – caused by ink not adhering properly to paper

- Mottling – caused by uneven ink distribution

- Preventing defects involves:

- Proper press setup and calibration

- Using high-quality paper and ink

- Regular press maintenance

7. What is the role of press maintenance in ensuring print quality?

- Regular press maintenance helps prevent breakdowns and ensures optimal performance.

- It includes tasks such as:

- Cleaning the press

- Replacing worn parts

- Performing calibration

8. What safety precautions should be taken when operating a printing press?

- Wear appropriate safety gear (gloves, goggles, etc.)

- Follow lockout/tagout procedures

- Never operate the press alone

- Be aware of pinch points and other hazards

- Report any safety concerns immediately

9. What is your experience with troubleshooting printing problems?

I have experience troubleshooting a variety of printing problems, including paper jams, ink smudging, and color registration issues. I am able to identify the root cause of the problem and implement solutions to resolve it quickly and efficiently.

10. What is your knowledge of the latest printing technologies?

I am familiar with the latest printing technologies, including digital printing, UV printing, and 3D printing. I am also aware of the latest trends in print finishing and packaging.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Large Sheetfed Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Large Sheetfed Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Large Sheetfed Press Operator is responsible for the safe and efficient operation of the large sheetfed press, ensuring the production of high-quality printed materials. The key responsibilities include:

1. Press Operation

Operate the large sheetfed press in accordance with established procedures, ensuring optimal performance and efficiency.

- Set up and adjust the press for different printing jobs, including loading and unloading paper, adjusting ink levels, and calibrating color.

- Monitor press operation, making adjustments as needed to maintain print quality and productivity.

2. Troubleshooting and Maintenance

Troubleshoot and resolve press malfunctions, identifying and repairing mechanical or electrical issues.

- Perform regular maintenance and cleaning of the press, ensuring smooth operation and preventing breakdowns.

- Collaborate with mechanics to diagnose and repair complex press issues.

3. Quality Control

Inspect printed materials for defects, ensuring that they meet the required quality standards.

- Use measuring tools and other quality control devices to verify print accuracy, color consistency, and paper quality.

- Identify and rectify printing errors promptly to minimize waste and ensure customer satisfaction.

4. Safety and Compliance

Adhere to established safety regulations and procedures, ensuring a safe work environment for all.

- Follow proper lifting and handling techniques to prevent injuries.

- Maintain a clean and organized work area, minimizing hazards and spills.

- Comply with environmental regulations and procedures related to press operation and waste disposal.

Interview Tips

To ace the interview for the Large Sheetfed Press Operator position, candidates should prepare thoroughly and demonstrate their skills and experience. Here are some interview tips to help candidates succeed:

1. Research the Company and Position

Research the company’s history, values, and the specific requirements of the Large Sheetfed Press Operator position. This will help candidates understand the company’s culture and the expectations for the role.

- Visit the company’s website and social media profiles to gather information about their products, services, and industry standing.

- Use job search websites and online resources to learn more about the typical responsibilities and qualifications for Large Sheetfed Press Operators.

2. Highlight Relevant Skills and Experience

During the interview, candidates should emphasize their skills and experience that are most relevant to the Large Sheetfed Press Operator role. They should provide specific examples of their accomplishments and how they have contributed to the success of previous employers.

- Quantify their results whenever possible, using numbers and metrics to demonstrate their impact.

- Be prepared to discuss their experience in operating large sheetfed presses, troubleshooting and resolving malfunctions, and ensuring print quality.

3. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that candidates are engaged and interested in the position. Questions should be specific to the company, the role, or the industry.

- Inquire about the company’s plans for future growth and development.

- Ask about the training and support provided to employees.

- Seek insights into the company’s commitment to safety and environmental sustainability.

4. Be Professional and Enthusiastic

Candidates should maintain a professional demeanor throughout the interview, dress appropriately, and arrive on time. They should be enthusiastic about the opportunity and convey their passion for the printing industry.

- Make eye contact with the interviewer, speak clearly, and actively listen to their questions.

- Express gratitude for the opportunity to interview and reiterate their interest in the position.

- Follow up with a thank-you note after the interview, expressing appreciation for the interviewer’s time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Large Sheetfed Press Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!