Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Laser Beam Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

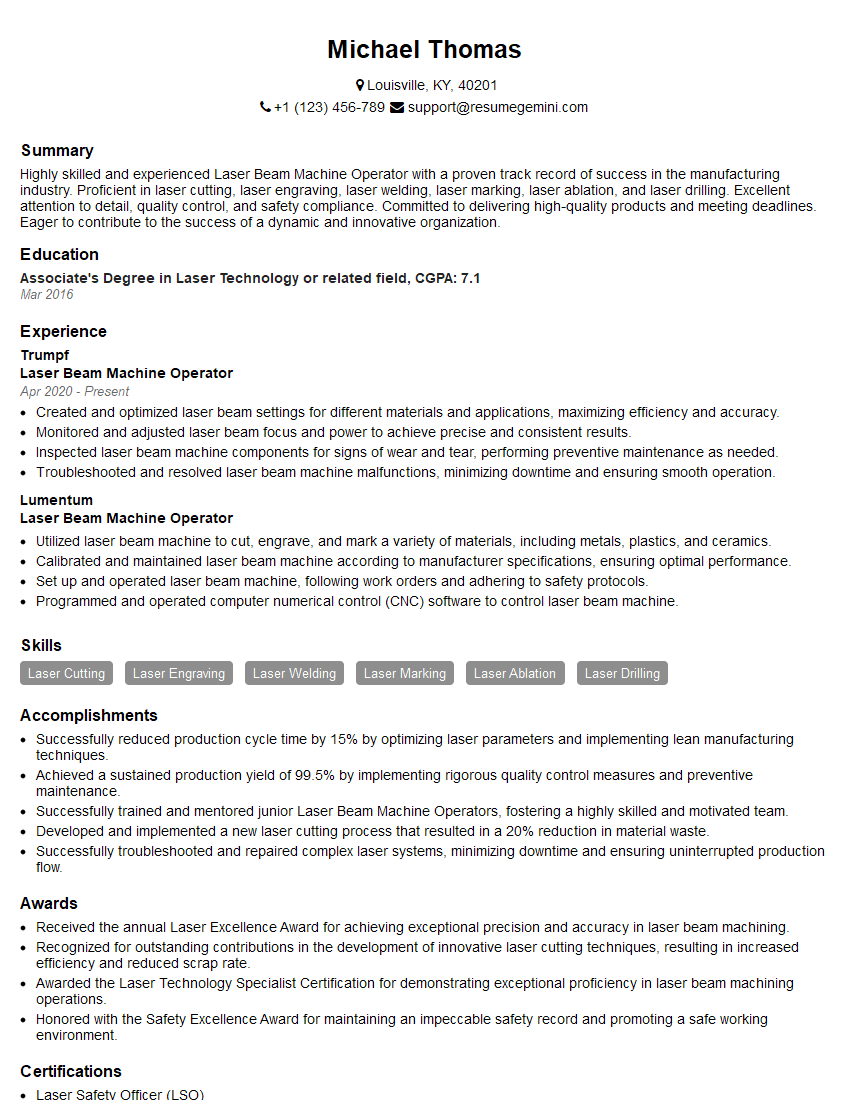

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Laser Beam Machine Operator

1. Describe the main components of a laser beam machine and their functions.

The main components of a laser beam machine include:

- Laser source: Generates the high-powered laser beam used for cutting or engraving.

- Beam delivery system: Directs the laser beam to the work surface.

- Cutting or engraving head: Focuses the laser beam on the workpiece.

- Control system: Manages the machine’s operation, including laser power, speed, and motion.

2. What are the different types of laser beam machines and their applications?

Types of laser beam machines

- CO2 laser: Used for cutting and engraving a wide range of materials, including metal, plastic, and wood.

- Fiber laser: Offers higher speed and efficiency, primarily used for metal cutting.

- YAG laser: Versatile and suitable for both cutting and welding applications.

Applications

- Laser cutting: Creating precise cuts in various materials for manufacturing, aerospace, and automotive industries.

- Laser engraving: Personalization, branding, and marking in industries such as electronics, jewelry, and medical devices.

- Laser welding: High-precision welding in delicate applications, such as microelectronics and medical devices.

3. Explain the process of laser beam machining, including setup, operation, and maintenance.

- Setup: Material selection, laser beam parameters, and machine calibration.

- Operation: Loading the material, initiating the laser beam, and monitoring the cutting or engraving process.

- Maintenance: Regular cleaning, alignment adjustments, and filter replacements to ensure optimal performance.

4. Describe the types of materials that can be processed using a laser beam machine.

Laser beam machines can process a wide range of materials, including:

- Metals: Steel, aluminum, stainless steel, titanium

- Plastics: Acrylic, polycarbonate, PVC

- Wood and engineered wood

- Glass and ceramics

- Fabrics and textiles

- Organic materials, such as paper and leather

5. Discuss the factors that influence the quality of laser beam machining.

- Laser beam parameters (power, wavelength, pulse duration)

- Workpiece material properties and surface quality

- Machine settings (speed, focus, gas flow)

- Proper setup, calibration, and maintenance

- Environmental factors (temperature, humidity)

6. How do you troubleshoot common problems encountered while operating a laser beam machine?

- Poor cut quality: Check laser power, focus, nozzle condition, and material quality.

- Machine malfunctions: Verify electrical connections, water flow, and error codes.

- Laser beam misalignment: Realign the laser beam path using reference points.

- Excessive smoke or fumes: Adjust gas flow, ventilation, or consider using a different material.

- Safety concerns: Ensure proper use of personal protective equipment, follow laser safety protocols, and inspect the machine regularly.

7. How do you maintain and calibrate a laser beam machine to ensure optimal performance?

- Routine cleaning: Remove debris, dust, and contaminants from mirrors, lenses, and nozzles.

- Alignment adjustments: Regularly align the laser beam path using calibration tools.

- Filter replacements: Replace air and water filters to maintain optimal performance and prevent clogs.

- Software updates: Install software updates to enhance functionality and address any software issues.

- Inspections: Conduct regular inspections to identify potential problems or areas for improvement.

8. What are some advanced techniques used in laser beam machining?

- 3D laser cutting: Creating complex 3D shapes and structures.

- Laser micromachining: Precise cutting and engraving on a microscopic scale.

- Laser marking: Non-contact marking for traceability, identification, and branding.

- Laser welding: High-precision welding with minimal heat-affected zones.

- Laser ablation: Selective removal of material layers for surface modification or cleaning.

9. How do you stay up-to-date with the latest advancements in laser beam machining technology?

- Attend industry conferences and webinars.

- Read technical journals and research papers.

- Consult with equipment manufacturers and suppliers.

- Participate in online forums and discussion groups.

- Seek opportunities for professional development and training.

10. Provide an example of a complex or challenging project you have worked on involving laser beam machining.

I recently worked on a project to create intricate 3D metal parts for a medical device. The parts required high precision, smooth surfaces, and tight tolerances. I used a 5-axis laser beam machining system to cut and weld the components, ensuring accuracy and meeting the demanding specifications of the project.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Laser Beam Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Laser Beam Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Laser Beam Machine Operators are responsible for operating, monitoring, and maintaining laser beam machines and other equipment used in the production of precision components and devices.

1. Machine Operation

Operate laser beam machines to cut, engrave, or mark materials according to specified designs and tolerances.

2. Material Handling

Load and unload materials onto the machine, ensuring proper alignment and safety.

3. Process Monitoring

Monitor the laser beam machine’s performance, including power output, beam quality, and focus.

4. Quality Control

Inspect finished products for defects, ensuring they meet quality standards and customer specifications.

5. Machine Maintenance

Perform routine maintenance on laser beam machines, including cleaning, lubrication, and calibration.

6. Safety Procedures

Adhere to all safety procedures and protocols, including proper handling of laser beams and hazardous materials.

Interview Preparation Tips

Preparation is key to acing a Laser Beam Machine Operator interview. Here are some specific tips to help you succeed:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This knowledge will help you demonstrate your understanding of the role and the company’s needs.

2. Practice Common Interview Questions

Prepare for questions about your technical skills, experience with laser beam machines, and quality control practices. Consider using the STAR method (Situation, Task, Action, Result) to provide clear and concise answers.

3. Highlight Your Safety Awareness

Laser beam machines require a high level of safety consciousness. Emphasize your knowledge of safety protocols and your commitment to maintaining a safe work environment.

4. Showcase Your Problem-Solving Skills

Interviewers often ask about your ability to troubleshoot and solve problems. Provide examples of when you successfully resolved issues related to laser beam machine operation or quality control.

5. Quantify Your Accomplishments

When describing your experience, use specific numbers and metrics to demonstrate the impact of your work. For instance, you could highlight how you improved production efficiency or reduced waste by optimizing laser beam machine settings.

6. Ask Insightful Questions

At the end of the interview, prepare thoughtful questions that show your interest in the role and the company. This is an opportunity to gather more information and demonstrate your engagement.

7. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for an industrial setting and arrive punctually for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Laser Beam Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!