Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Laserist interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Laserist so you can tailor your answers to impress potential employers.

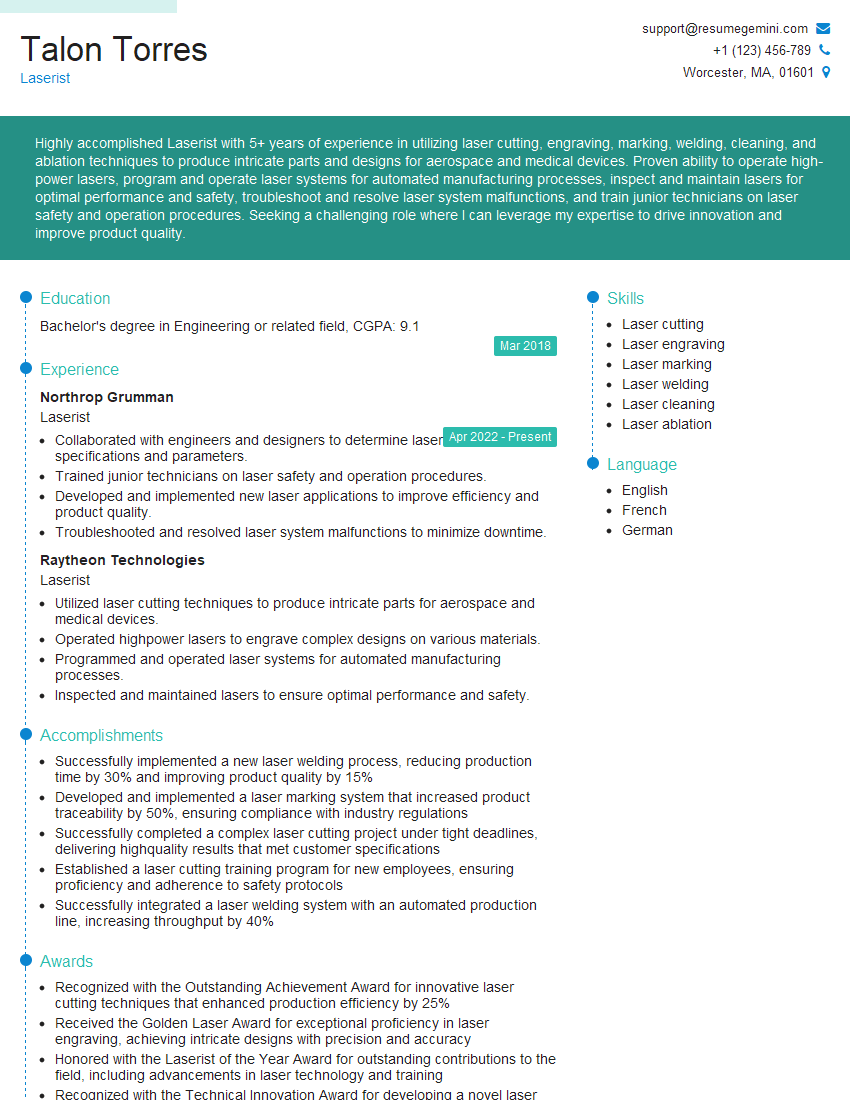

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Laserist

1. Explain the process of laser engraving and how it differs from laser cutting?

Laser engraving is a process that uses a laser to create a design on a surface by removing material, while laser cutting uses a laser to cut through a material. Laser engraving is typically used for creating decorative designs or logos, while laser cutting is used for cutting out shapes or components from a material.

- Laser engraving removes material from the surface of a material to create a design, while laser cutting cuts through the entire material.

- Laser engraving is typically used for creating decorative designs or logos, while laser cutting is used for cutting out shapes or components from a material.

2. What are the different types of lasers used in laser engraving and cutting?

Types of lasers used in laser engraving and cutting:

- CO2 lasers: These are the most common type of laser used in laser engraving and cutting. They produce a wavelength of 10.6 μm, which is well-suited for cutting and engraving a wide variety of materials, including wood, plastic, and metal.

- Nd:YAG lasers: These lasers produce a wavelength of 1.064 μm, which is shorter than CO2 lasers. This makes them more suitable for finer and more precise engraving and cutting, but they are also more expensive.

- Fiber lasers: These lasers produce a wavelength of 1.06 μm, which is similar to Nd:YAG lasers. However, they are more efficient and have a longer lifespan than Nd:YAG lasers, making them a good choice for high-volume engraving and cutting applications.

3. What are the factors that affect the quality of laser engraving and cutting?

The quality of laser engraving and cutting depends on a number of factors, including the following:

- Laser power: The power of the laser determines the depth and width of the engraving or cut.

- Laser wavelength: The wavelength of the laser determines the type of material that can be engraved or cut.

- Laser beam quality: The quality of the laser beam determines the precision and accuracy of the engraving or cut.

- Material properties: The properties of the material being engraved or cut, such as its hardness and thickness, affect the quality of the engraving or cut.

4. How do you set up and calibrate a laser engraving or cutting machine?

Procedure for setting up and calibrating a laser engraving or cutting machine:

- Install the laser machine: Place the laser machine on a stable and level surface. Connect the laser machine to a power source and computer.

- Install the laser software: Install the laser software on the computer. The software will allow you to control the laser machine and create designs.

- Calibrate the laser machine: Calibrate the laser machine by following the manufacturer’s instructions. This will ensure that the laser is accurately aligned and focused.

- Test the laser machine: Test the laser machine by engraving or cutting a small piece of material. This will help you to ensure that the laser machine is working properly.

5. What are the safety precautions that must be taken when operating a laser engraving or cutting machine?

Safety precautions for operating a laser engraving or cutting machine:

- Wear proper safety gear: Wear safety glasses, gloves, and a lab coat when operating a laser engraving or cutting machine.

- Keep the work area clean: Keep the work area clean and free of debris. This will help to prevent fires and other accidents.

- Never look directly into the laser beam: The laser beam can damage your eyes. Never look directly into the laser beam, even if the laser is turned off.

- Do not leave the laser unattended: Never leave the laser unattended while it is in operation. If you need to leave the work area, turn off the laser and unplug it.

6. What are the different applications of laser engraving and cutting?

Applications of laser engraving and cutting:

- Industrial applications: Laser engraving and cutting are used in a variety of industrial applications, such as manufacturing, prototyping, and product development.

- Commercial applications: Laser engraving and cutting are used in a variety of commercial applications, such as signage, engraving, and product decoration.

- Consumer applications: Laser engraving and cutting are used in a variety of consumer applications, such as home decorating, crafting, and jewelry making.

7. What are the advantages and disadvantages of laser engraving and cutting?

Advantages of laser engraving and cutting:

- Precision: Laser engraving and cutting can produce very precise and accurate results.

- Versatility: Laser engraving and cutting can be used on a wide variety of materials.

- Speed: Laser engraving and cutting can be very fast, especially when compared to other methods of engraving and cutting.

- Automation: Laser engraving and cutting can be automated, which can save time and money.

Disadvantages of laser engraving and cutting:

- Cost: Laser engraving and cutting machines can be expensive, especially for large-scale operations.

- Safety: Laser engraving and cutting machines can be dangerous if not used properly. It is important to follow all safety precautions when operating a laser engraving or cutting machine.

8. What are the latest trends in laser engraving and cutting technology?

Latest trends in laser engraving and cutting:

- Fiber lasers: Fiber lasers are becoming increasingly popular for laser engraving and cutting. Fiber lasers are more efficient and have a longer lifespan than other types of lasers.

- Ultrafast lasers: Ultrafast lasers are capable of producing very high-quality engravings and cuts. Ultrafast lasers are typically used for applications that require precision and accuracy.

- 3D laser engraving and cutting: 3D laser engraving and cutting is a new technology that allows you to create three-dimensional objects. 3D laser engraving and cutting is typically used for applications such as prototyping and product development.

9. What are the career opportunities for laserists?

Career opportunities for laserists:

- Laser technician: Laser technicians operate and maintain laser engraving and cutting machines. They may also be responsible for developing and testing laser engraving and cutting processes.

- Laser engineer: Laser engineers design and develop laser engraving and cutting systems. They may also be responsible for researching and developing new laser technologies.

- Laser sales engineer: Laser sales engineers sell laser engraving and cutting machines and systems. They may also provide training and support to customers.

10. What are the key skills and qualifications that employers are looking for in laserists?

Skills and qualifications that employers are looking for in laserists:

- Technical skills: Laserists should have a strong understanding of laser engraving and cutting technology. They should also be proficient in operating and maintaining laser engraving and cutting machines.

- Communication skills: Laserists should be able to communicate effectively with customers, colleagues, and supervisors. They should also be able to write technical reports and documentation.

- Problem-solving skills: Laserists should be able to troubleshoot and solve problems quickly and efficiently. They should also be able to develop and implement new solutions to improve laser engraving and cutting processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Laserist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Laserist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Laserists are responsible for operating and maintaining laser systems used in various industries, including manufacturing, medical, and research. Their key job responsibilities include:

1. Laser Operation

Operate laser systems to perform tasks such as cutting, engraving, welding, and marking on various materials.

- Set up and calibrate laser systems.

- Monitor and adjust laser parameters to achieve desired results.

2. System Maintenance

Perform routine maintenance and repairs on laser systems to ensure optimal performance.

- Clean and inspect laser components regularly.

- Replace worn or damaged parts.

- Troubleshoot and resolve system malfunctions.

3. Material Handling

Handle and prepare materials for laser processing, ensuring proper alignment and positioning.

- Load and unload materials into laser systems.

- Ensure materials meet specifications for laser processing.

4. Quality Control

Inspect and evaluate laser-processed materials to ensure they meet quality standards.

- Use measuring instruments to verify dimensions and tolerances.

- Record and document inspection results.

- Identify and address quality issues.

5. Safety Compliance

Adhere to strict safety protocols when operating laser systems.

- Wear appropriate personal protective equipment (PPE).

- Follow established safety procedures.

- Maintain a clean and organized work area.

Interview Tips

To ace an interview as a Laserist, consider the following preparation tips:

1. Research the Company and Role

Familiarize yourself with the company’s industry, products, and specific requirements for the Laserist position.

- Visit the company website and study their mission, values, and current projects.

- Read industry-specific publications and articles to stay up-to-date on the latest trends and technologies.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in laser operation, maintenance, and material handling. Quantify your accomplishments and provide specific examples of your work.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Prepare examples that demonstrate your ability to troubleshoot and resolve technical issues.

3. Be Prepared for Technical Questions

Expect questions related to laser physics, system components, and safety protocols. Review basic concepts and practice answering technical questions clearly and concisely.

- Study the principles of laser operation, including beam characteristics and power control.

- Prepare to discuss different types of laser systems and their applications.

4. Demonstrate Safety Awareness

Emphasize your understanding of laser safety protocols and procedures. Show that you are committed to maintaining a safe work environment.

- Review laser safety regulations and best practices.

- Prepare to discuss your experience in handling laser equipment and adhering to safety guidelines.

5. Practice and Prepare

Practice answering common interview questions by using the tips provided above. The more prepared you are, the more confident you will be during the interview.

- Seek feedback from a friend, family member, or career counselor on your practice responses.

- Dress professionally and arrive on time for the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Laserist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Laserist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.