Are you gearing up for a career in Last Model Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Last Model Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

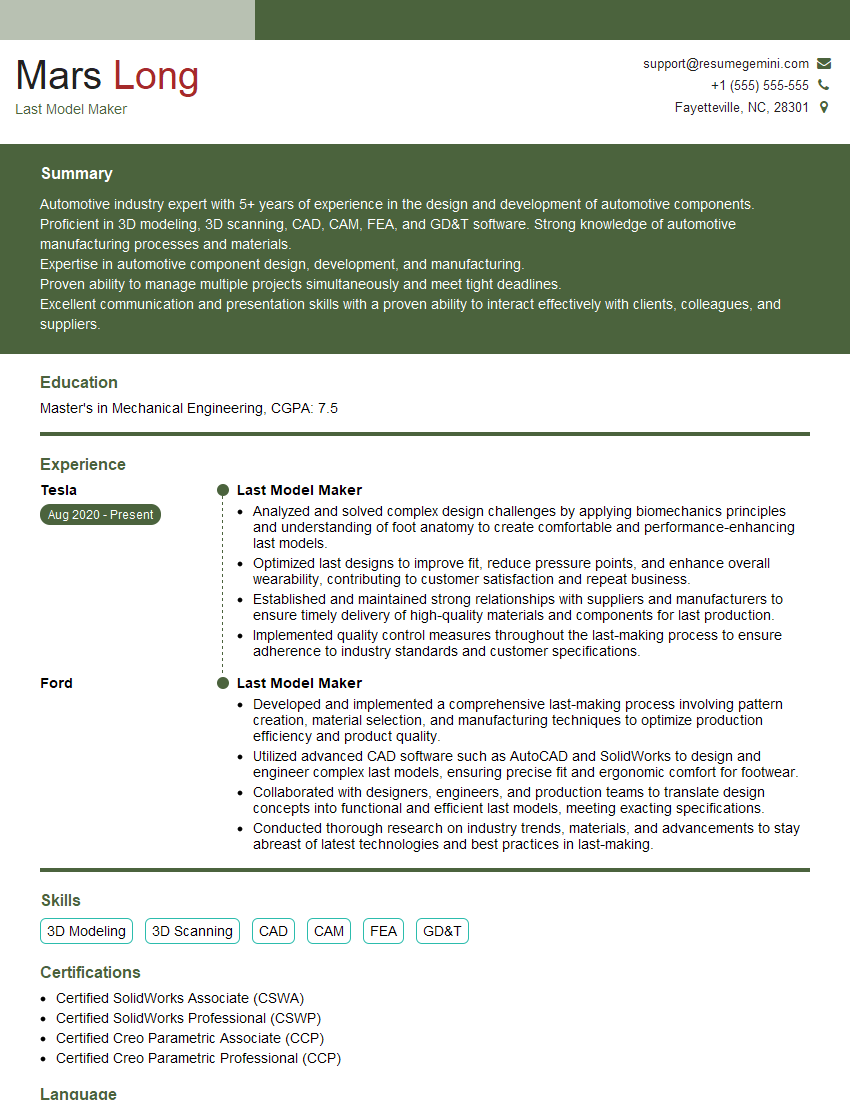

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Last Model Maker

1. What are the different types of materials used in last making?

Different types of materials used in last making include:

- Wood: Beechwood, hornbeam, ash, maple, mahogany, and others

- Plastics: Polyurethane, polypropylene, and others

- Metals: Aluminum, titanium, and others

- Fibers: Carbon fiber, fiberglass, and others

- Cork: Used for filling and cushioning

2. Describe the process of creating a custom-made last.

Taking Measurements

- Capture the shape and dimensions of the foot using a 3D scanner or traditional methods like plaster casting

- Analyze the measurements to determine the necessary adjustments and modifications

Designing the Last

- Use computer-aided design (CAD) software to create the 3D model of the last based on the measurements

- Consider factors like foot type, arch height, and specific requirements of the footwear

Creating the Physical Last

- Carve the last from a solid block of wood or mold it using plastic or other materials

- Sand and refine the last to achieve the desired shape and smoothness

- Apply coatings or finishes to enhance durability

3. What are the key factors to consider when designing a last for a specific type of footwear?

Key factors to consider when designing a last for a specific type of footwear include:

- Purpose of the footwear: Athletic, dress, casual, etc.

- Foot type: Normal, high arch, flat foot, etc.

- Gender: Male, female, or unisex

- Style and aesthetics

- Fit and comfort requirements

- Materials and construction methods

4. What are the common problems that can occur during last making and how do you address them?

Common problems that can occur during last making and how to address them:

- Incorrect measurements: Remeasure the foot and adjust the last accordingly.

- Poorly carved or molded last: Recarve or remold the last to achieve the desired shape and smoothness.

- Uneven or distorted last: Sand and refine the last to correct any unevenness or distortion.

- Defects in materials: Replace the defective material or use a different material.

- Inadequate finishing: Apply additional coatings or finishes to enhance durability and prevent premature wear.

5. What are the latest advancements in last making technology?

Latest advancements in last making technology include:

- 3D scanning: Captures precise foot measurements for custom-made lasts.

- Computer-aided design (CAD): Enables the creation of complex and accurate last designs.

- Additive manufacturing (3D printing): Creates intricate last shapes and geometries not possible with traditional methods.

- Virtual reality (VR): Allows for realistic visualization and fitting of lasts before physical production.

6. How do you stay up to date with the latest trends and developments in last making?

To stay up to date with the latest trends and developments in last making, I:

- Attend industry conferences and workshops

- Read trade publications and online resources

- Collaborate with other last makers and footwear professionals

- Experiment with new materials and techniques

7. Describe a challenging project you worked on as a last model maker and how you overcame the challenges.

Recently, I worked on a project to create a custom last for a high-end dress shoe. The client had a unique foot shape and required a last that would provide both comfort and a stylish silhouette. I overcame the following challenges:

- Complex foot measurements: I used a combination of 3D scanning and traditional methods to capture the intricate details of the client’s foot.

- Intricate last design: The desired shoe style required a last with a specific toe shape and heel height. I used CAD software to create a complex 3D model that met the client’s requirements.

- Material selection: To ensure durability and a premium look, I selected a combination of woods and plastics for the last.

Through careful planning, skilled craftsmanship, and collaboration with the client, I successfully overcame these challenges and created a last that exceeded the client’s expectations.

8. How do you ensure quality control in the last making process?

To ensure quality control, I implement the following measures:

- Precise measurements: I use calibrated measuring tools and follow strict measurement protocols to ensure accurate last shapes.

- Material inspection: I inspect the raw materials used for any defects or imperfections before last making begins.

- Regular calibration: I regularly calibrate my equipment and tools to maintain accuracy and precision.

- Visual inspection: I carefully inspect each completed last for any imperfections in shape, smoothness, or finish.

- Fit testing: I conduct fit tests using lasts to ensure they provide the desired comfort and fit before they are sent to customers.

9. How do you manage multiple projects simultaneously and prioritize your workload?

To manage multiple projects simultaneously and prioritize my workload, I follow these strategies:

- Project planning: I plan each project carefully, outlining the tasks, timelines, and resources needed.

- Priority setting: I prioritize projects based on urgency, deadlines, and client requirements.

- Time management: I use time management techniques such as task lists, calendars, and time blocking to allocate my time efficiently.

- Collaboration: I collaborate with colleagues and team members to share workload and ensure smooth project execution.

- Regular reassessment: I regularly reassess my workload and adjust priorities as needed to ensure timely completion of all projects.

10. What are your strengths and weaknesses as a last model maker?

Strengths:

- Exceptional craftsmanship and attention to detail

- Strong understanding of foot anatomy and last design principles

- Proficiency in using CAD software and 3D scanning technology

- Ability to create custom lasts that meet specific requirements

- Excellent problem-solving and troubleshooting skills

Weaknesses:

- Limited experience in high-volume last production

- Working under tight deadlines can sometimes be challenging

I am actively working on improving my weaknesses by seeking opportunities for professional development and collaboration with experienced professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Last Model Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Last Model Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Last Model Maker is responsible for creating the final models used in the production of a product.

1. Model Creation

This involves designing and building the model, as well as making any necessary modifications or repairs.

- Follow design specifications and blueprints to create accurate and detailed models.

- Utilize various materials and techniques to construct models, including wood, metal, plastic, and clay.

- Ensure dimensional accuracy and surface finish of models meet quality standards.

2. Model Maintenance

Last Model Makers are also responsible for maintaining the models, which includes cleaning, repairing, and storing them.

- Regularly inspect models for damage or wear and tear.

- Perform necessary repairs or modifications to ensure models remain in optimal condition.

- Properly store models in a secure and climate-controlled environment.

3. Quality Control

They also conduct quality control checks to ensure that the models meet the required standards.

- Inspect models for defects, imperfections, or deviations from specifications.

- Implement corrective measures or collaborate with engineers to resolve quality issues.

- Maintain records and documentation of quality control inspections.

4. Collaboration and Communication

Last Model Makers collaborate with engineers, designers, and production staff to ensure that the models meet the specifications and requirements for the final product.

- Participate in design reviews and provide feedback on model designs.

- Communicate with production staff to provide instructions and ensure model usage is optimized.

- Coordinate with other departments to resolve production issues or implement model modifications.

Interview Tips

To ace an interview for a Last Model Maker position, it is essential to prepare thoroughly and showcase your skills and experience that align with the key job responsibilities.

1. Research the Company and Role

Familiarize yourself with the company’s products, industry, and specific requirements for the Last Model Maker role. This demonstrates your interest and understanding of the position.

- Visit the company’s website, read industry publications, and network with professionals in the field.

- Identify specific projects or models you have worked on that are relevant to the job requirements.

2. Highlight Your Skills and Experience

Emphasize your technical skills in model creation, maintenance, and quality control. Provide specific examples and quantify your accomplishments whenever possible.

- Describe your experience with different materials, techniques, and software used in model making.

- Showcase your proficiency in quality control procedures and demonstrate your commitment to delivering high-quality models.

3. Prepare for Technical Questions

Expect to answer technical questions about your model-making process, materials, and quality standards. Be prepared to discuss your approach to problem-solving and your ability to work independently and as part of a team.

- Review common materials and techniques used in model making, as well as industry standards for model accuracy.

- Practice answering questions about your troubleshooting and problem-solving skills.

4. Demonstrate Your Passion for Model Making

Convey your enthusiasm for the craft and your dedication to creating high-quality models. Explain why you are interested in the Last Model Maker role and how your skills and experience make you a valuable asset to the team.

- Share examples of projects you have undertaken outside of work that demonstrate your passion for model making.

- Express your eagerness to contribute your expertise to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Last Model Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.