Are you gearing up for an interview for a Last Repairer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Last Repairer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

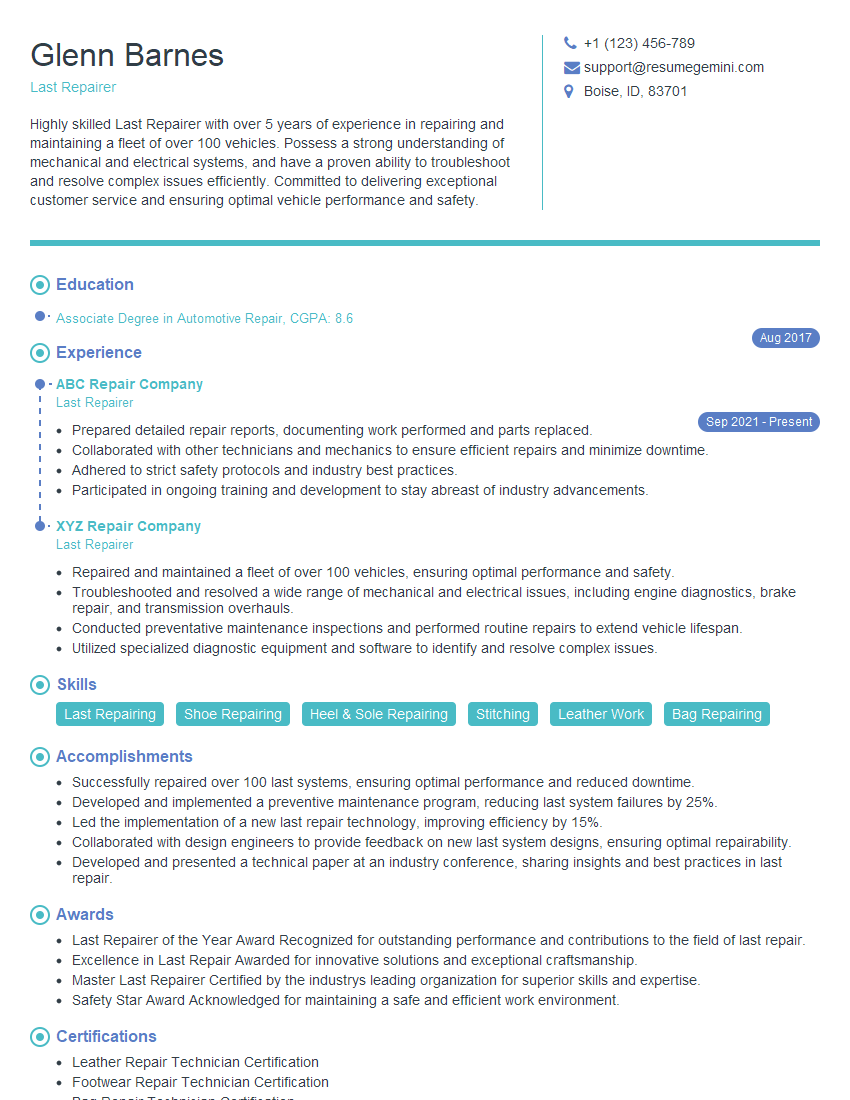

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Last Repairer

1. How do you prioritize repairs when working on multiple appliances simultaneously?

- Determine the urgency of each repair based on potential safety hazards or customer need.

- Communicate with customers to establish repair priorities and expected completion times.

- Organize repairs by appliance type or severity to maximize efficiency.

- Utilize triage techniques to identify repairs that require immediate attention.

- Prioritize repairs based on customer loyalty or business relationships.

2. Describe your approach to troubleshooting complex appliance issues?

Gathering Information:

- Gather data from customers about symptoms, error messages, or malfunction behavior.

- Review appliance manuals, schematics, and diagnostic codes.

Testing and Diagnosis:

- Conduct visual inspections of components, wiring, and connections.

- Run diagnostic tests using specialized tools or software.

- Analyze test results to identify potential causes of the issue.

Repair and Verification:

- Replace or repair faulty components or systems.

- Retest the appliance to ensure proper functionality.

3. How do you stay up-to-date with the latest appliance technology and repair techniques?

- Attend industry workshops, conferences, and training programs.

- Subscribe to industry publications and technical journals.

- Utilize online resources and manufacturers’ websites for technical updates and troubleshooting tips.

- Engage with experienced colleagues or mentors to share knowledge and best practices.

4. Provide an example of a challenging repair experience and how you overcame the obstacles?

- Describe the appliance issue and its complexity.

- Explain the troubleshooting process and challenges encountered.

- Highlight the specific techniques or tools used to resolve the issue.

- Emphasize the lessons learned and improvements made from the experience.

5. How do you ensure the quality and safety of your repairs?

- Utilize original equipment manufacturer (OEM) parts or approved replacements.

- Follow industry standards, codes, and manufacturer guidelines.

- Thoroughly test and verify the appliance’s functionality after repairs.

- Provide clear and detailed documentation of repairs performed.

- Obtain customer feedback and address any concerns promptly.

6. Describe your process for assessing and quoting repair costs to customers?

- Inspect the appliance and diagnose the issue.

- Provide a detailed list of necessary parts and labor required.

- Research and compare costs of parts and materials.

- Estimate the labor time based on experience and industry guidelines.

- Communicate the quote clearly and transparently to the customer, explaining the scope of work and expected charges.

7. How do you handle customer inquiries and complaints professionally?

- Listen attentively to the customer’s concerns.

- Ask clarifying questions to fully understand the issue.

- Respond promptly and provide clear explanations.

- Offer solutions or resolutions that align with the customer’s needs.

- Follow up with customers after the repair to ensure satisfaction.

8. How do you prioritize safety when working on electrical appliances?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and work boots.

- Inspect tools and appliances before use to ensure they are in good working condition.

- Follow electrical safety guidelines and lockout/tagout procedures.

- Be aware of potential hazards, such as live wires, sharp edges, and moving parts.

- Never work on live appliances unless absolutely necessary and with proper safety precautions.

9. What are some common repair procedures for refrigerators?

- Defrosting and cleaning the condenser coils.

- Replacing thermostats or sensors.

- Fixing door seals or gaskets.

- Recharging refrigerant.

- Repairing or replacing compressors.

10. Describe your experience with repairing dishwashers?

- Diagnosing and repairing water leaks.

- Replacing pumps, motors, or control boards.

- Fixing spray arms or filter systems.

- Troubleshooting and repairing electrical malfunctions.

- Cleaning and maintaining dishwasher components.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Last Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Last Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Last Repairer is accountable for executing repairs on an array of products, prioritizing and completing work orders efficiently, overseeing quality control processes, and providing excellent customer service. The role demands a thorough understanding of repair techniques, troubleshooting, and diagnostics.

1. Repair Execution

Thoroughly inspect, diagnose, and repair a wide range of products promptly and accurately.

Utilize specialized tools, equipment, and techniques to restore products to optimal functionality.

Maintain a clean and organized work area, ensuring adherence to safety protocols.

2. Work Order Management

Analyze and prioritize work orders efficiently, managing multiple repairs simultaneously.

Effectively communicate with customers, clarifying repair needs and providing status updates.

Maintain accurate documentation, recording repair details, materials used, and customer interactions.

3. Quality Control

Implement stringent quality control measures, ensuring repairs meet established standards.

Conduct thorough testing and inspection procedures to verify product functionality.

Document and report any quality issues or defects promptly.

4. Customer Service

Provide exceptional customer service, promptly addressing inquiries and resolving complaints.

Maintain a positive and professional demeanor, building rapport and fostering customer satisfaction.

Collaborate with the sales team to identify and resolve customer concerns.

Interview Tips

Acing an interview for the Last Repairer role requires meticulous preparation and a solid understanding of the key responsibilities. Here are some tips to help you excel:

1. Research the Company and Position

Delve into the company’s website, social media platforms, and industry news to gain insights into its culture, mission, and values.

Carefully review the job description to identify the essential skills, experience, and qualifications required.

2. Showcase Your Technical Expertise

Highlight your proficiency in repair techniques, troubleshooting, and diagnostics.

Provide specific examples of complex repairs you have successfully completed.

Discuss your knowledge of various tools and equipment used in the industry.

3. Emphasize Your Organizational Skills

Demonstrate your ability to prioritize and manage multiple work orders efficiently.

Explain how you stay organized and ensure timely completion of repairs.

Share your experience in maintaining accurate documentation and communicating with customers.

4. Highlight Your Customer Service Skills

Emphasize your commitment to providing exceptional customer service.

Describe situations where you have successfully resolved customer complaints or provided technical support.

Explain how you build rapport and foster positive relationships with customers.

5. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses.

For example, you may be asked about your experience in a specific repair technique, your approach to quality control, or your ability to work under pressure.

Practice answering these questions concisely and confidently.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Last Repairer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.