Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lathe Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

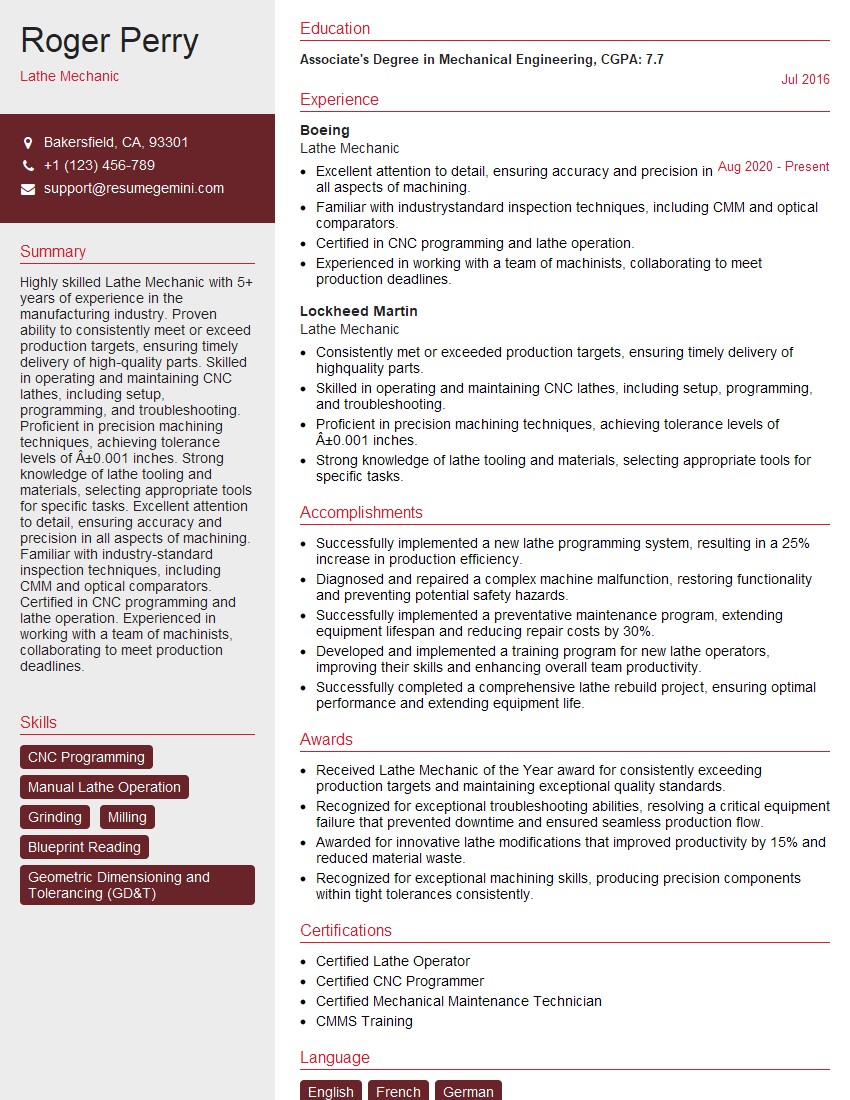

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lathe Mechanic

1. Describe the process of setting up a lathe machine for a specific job?

The process of setting up a lathe machine for a specific job involves several steps to ensure accuracy and efficiency.

- Choose the correct lathe: Select a lathe with the appropriate size and capacity for the job.

- Mount the workpiece: Secure the workpiece properly using a chuck, faceplate, or other holding device.

- Select and install the cutting tool: Choose the appropriate cutting tool based on the material and the desired cut. Install it securely in the tool holder.

- Set the speed and feed rates: Determine the optimal speed and feed rates for the material and cutting tool being used.

- Adjust the tool offset: Calibrate the tool offset to ensure the cutting tool aligns precisely with the workpiece.

- Zero the machine: Set the machine’s reference point to zero to ensure accurate measurements.

- Run a test cut: Perform a small test cut to check the setup and make any necessary adjustments.

2. What are the different types of lathe operations and their applications?

Turning

- Creating cylindrical or tapered surfaces

- Facing (creating flat surfaces)

Boring

- Enlarging or finishing existing holes

- Creating internal surfaces

Threading

- Creating internal or external threads

- Used for fasteners, connections, and fluid fittings

Knurling

- Creating a textured surface for better grip

- Used on handles, knobs, and other components

Drilling

- Creating holes in workpieces

- Used for mounting, fastening, and fluid passages

3. How do you maintain the accuracy of a lathe machine?

Maintaining the accuracy of a lathe machine is crucial for producing precise and consistent parts.

- Regular calibration: Regularly calibrate the lathe to ensure its precision and accuracy.

- Proper lubrication: Lubricate all moving parts to minimize friction and wear.

- Sharpened cutting tools: Use sharp cutting tools to achieve clean cuts and maintain accuracy.

- Clean and aligned machine: Keep the lathe clean and its components aligned to prevent errors.

- Temperature control: Maintain a consistent temperature in the work area to minimize thermal expansion.

4. What are the safety precautions to observe when operating a lathe machine?

Operating a lathe machine requires adherence to strict safety precautions to prevent injuries and accidents.

- Wear appropriate safety gear: Including eye protection, gloves, and protective clothing.

- Secure the workpiece: Ensure the workpiece is securely mounted before starting the machine.

- Keep the work area clean: Clear away any chips, debris, or tools from the work area.

- Stay focused and alert: Pay attention to the machine’s operation and be aware of any potential hazards.

- Use proper techniques: Follow established procedures and techniques for operating the lathe safely.

5. How do you handle and measure different types of materials on a lathe machine?

Handling and measuring different materials on a lathe machine requires specific techniques to ensure accuracy and prevent damage.

- Metals: Use proper cutting tools and techniques for the specific metal being machined.

- Plastics: Consider the material’s properties and use appropriate speeds and feeds to avoid melting or distortion.

- Wood: Use sharp tools and pay attention to grain direction to achieve clean cuts.

- Measuring techniques: Use precision measuring tools such as calipers, micrometers, and dial indicators to measure dimensions accurately.

6. Describe the different types of cutting tools used in lathe operations and their applications.

- Turning tools: Used for creating cylindrical and tapered surfaces, facing, and grooving.

- Boring tools: Designed for enlarging or finishing existing holes or creating internal surfaces.

- Threading tools: Used for cutting internal or external threads.

- Knurling tools: Create textured surfaces for better grip.

- Drilling tools: For creating holes in workpieces.

7. How do you troubleshoot common problems that may occur during lathe operations?

Troubleshooting common problems that arise during lathe operations is essential to minimize downtime and maintain productivity.

- Excessive vibration: Check for unbalanced workpiece, loose components, or worn bearings.

- Poor surface finish: Examine the cutting tool for sharpness, adjust speeds and feeds, or consider different materials.

- Tool chatter: Reduce overhang, use a sharper tool, or adjust cutting parameters.

- Workpiece not running true: Check for proper mounting, damaged workpiece, or misaligned machine components.

8. What are the different types of lathe chucks and their applications?

- Three-jaw chuck: Versatile and commonly used for holding round or irregular-shaped workpieces.

- Four-jaw chuck: Used for holding square or rectangular workpieces or for precise centering.

- Collet chuck: Ideal for holding small-diameter workpieces or for high-precision applications.

- Magnetic chuck: Used for holding ferrous materials without the need for physical clamping.

9. Discuss the importance of coolant in lathe operations.

Coolant plays several critical roles in lathe operations:

- Cooling: Reduces the temperature of the cutting tool and workpiece, preventing overheating and tool wear.

- Lubrication: Acts as a lubricant between the cutting tool and workpiece, reducing friction and improving surface finish.

- Chip removal: Flushes away chips and debris from the cutting area, improving visibility and reducing tool wear.

- Corrosion protection: Protects the workpiece and cutting tool from corrosion.

10. How do you calculate cutting speeds and feed rates for different materials?

Calculating cutting speeds and feed rates is crucial for optimizing lathe operations and achieving desired results:

- Surface footage per minute (SFM): Determines the cutting speed based on the material being machined.

- RPM (Revolutions per minute): Calculates the spindle speed based on the SFM and the diameter of the workpiece.

- Feed rate: Determines the amount of material removed per revolution. Consider factors like material hardness and tool geometry.

- Reference tables and calculators: Use industry-recommended tables or online calculators to determine appropriate cutting parameters.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lathe Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lathe Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lathe Mechanics play a crucial role in the manufacturing industry, operating and maintaining lathe machines to produce precision parts. Their responsibilities encompass a wide range of tasks, including:

1. Machine Operation and Maintenance

Lathe Mechanics are responsible for the safe and efficient operation of lathe machines. They set up and operate CNC (Computer Numerical Control) lathes to produce parts according to blueprints and specifications.

- Set up and configure lathe machines

- Select and mount appropriate cutting tools

- Monitor machine performance and make adjustments as needed

- Perform routine maintenance and troubleshooting

2. Precision Machining

Lathe Mechanics use their skills and expertise to produce parts with precise dimensions and tolerances. They work with a variety of materials, including metals, plastics, and composites.

- Machine parts to meet specified dimensions and tolerances

- Use precision measuring tools to inspect and verify part quality

- Identify and correct defects in parts

3. Tooling and Fixture Selection

Lathe Mechanics must have a thorough understanding of tooling and fixtures used in lathe operations. They select and install the appropriate tools and fixtures to ensure efficient and accurate production.

- Select and install cutting tools, inserts, and workholding devices

- Set up and adjust fixtures to hold workpieces securely

- Maintain and repair tooling and fixtures

4. Quality Control

Lathe Mechanics are responsible for ensuring the quality of the parts they produce. They perform regular inspections and monitor production processes to identify and correct any potential issues.

- Inspect parts for dimensional accuracy and surface finish

- Identify and troubleshoot quality issues

- Implement corrective actions to improve quality

Interview Tips

Preparing thoroughly for an interview is essential for showcasing your skills and making a strong impression. Here are some tips to help you ace your interview for a Lathe Mechanic position:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Lathe Mechanic position you are applying for. This will help you understand the company’s culture, values, and the requirements of the role.

- Visit the company’s website and social media pages

- Review the job description and identify the key responsibilities and qualifications

- Prepare questions about the company, the position, and the industry

2. Practice Answering Common Interview Questions

Prepare for common interview questions by anticipating the types of questions you may be asked and rehearsing your answers. This will help you feel more confident and articulate during the interview.

- Tell me about yourself and your experience as a Lathe Mechanic

- What are your strengths and weaknesses as a Lathe Mechanic?

- How do you ensure the quality of the parts you produce?

- What are your experiences with different lathe machines and tooling?

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Lathe Mechanic position. Use specific examples to demonstrate your abilities and how you have contributed to previous roles.

- Quantify your accomplishments whenever possible, using specific numbers and metrics

- Provide examples of your problem-solving abilities and your attention to detail

- Emphasize your commitment to safety and your understanding of industry best practices

4. Ask Questions

At the end of the interview, take the opportunity to ask questions to show your interest and engagement. This is also a chance to clarify any information about the company or the position.

- Ask about the company’s growth plans and industry outlook

- Inquire about the training and development opportunities available

- Request specific details about the day-to-day responsibilities of the role

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lathe Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lathe Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.