Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lathe Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lathe Operator so you can tailor your answers to impress potential employers.

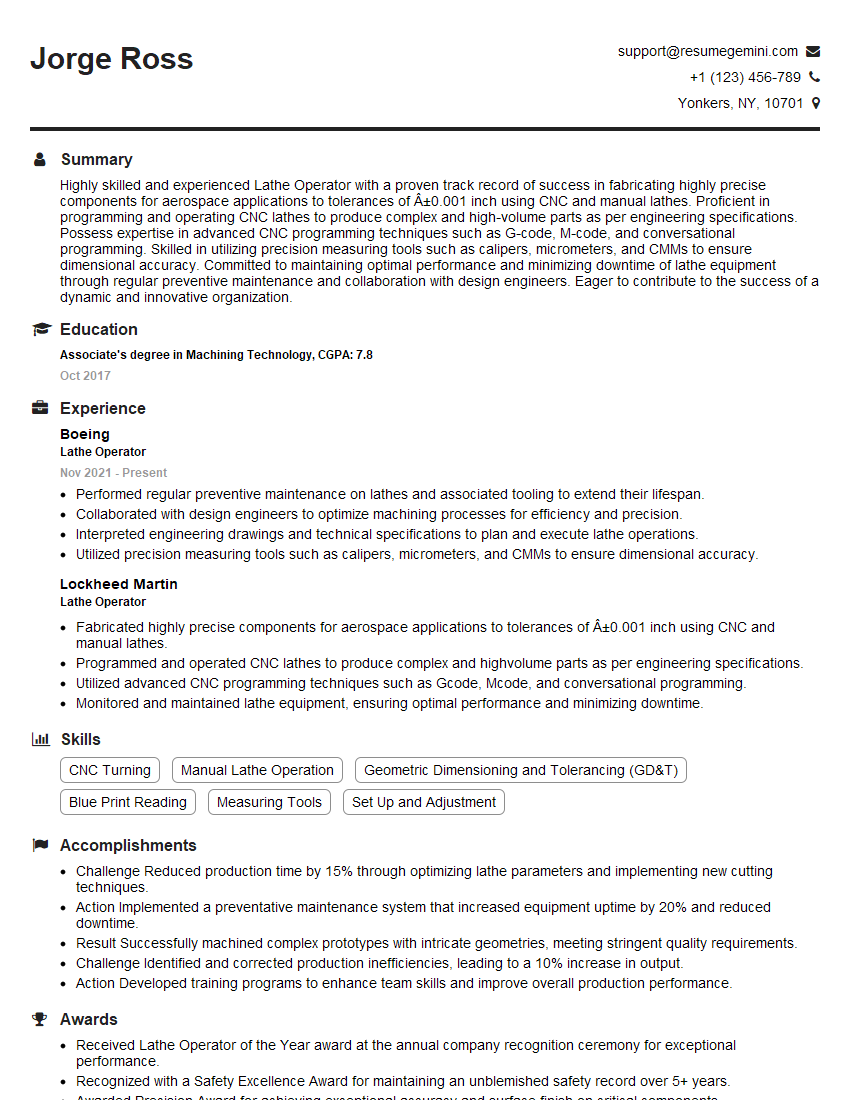

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lathe Operator

1. How do you ensure the accuracy and precision of the parts you are making?

To ensure accuracy and precision, I follow a meticulous process that involves:

- Precise Measurement: Using calipers, micrometers, and other precision measuring tools to verify dimensions throughout the machining process.

- Regular Instrument Calibration: Regularly calibrating measuring equipment to maintain their accuracy and prevent measurement errors.

- Attention to Detail: Paying close attention to machining parameters, tool selection, and cutting techniques to minimize variations and maintain tolerances.

2. Can you describe the different types of cutting tools used on a lathe?

Turning Tools

- Facing tools: Used to create flat surfaces perpendicular to the axis of rotation.

- Boring tools: Used to enlarge or create cylindrical holes.

- Knurling tools: Used to create textured grip surfaces on parts.

Threading Tools

- Single-point threading tools: Used to create external and internal threads.

- Thread inserts: Interchangeable inserts designed for specific thread profiles.

3. How do you calculate the speed and feed rates for a lathe operation?

To calculate speed and feed rates, I consider the following factors:

- Material of the workpiece: Different materials require different cutting speeds and feeds.

- Tool material: Harder tool materials allow for higher cutting speeds.

- Diameter of the workpiece: Larger diameters require lower cutting speeds.

- Depth of cut: Heavier cuts require lower feed rates to prevent tool failure.

I use formulas and reference tables to determine appropriate speed and feed rates for specific machining operations.

4. What is the purpose of coolant in lathe operations?

- Cooling the workpiece: Coolant helps dissipate heat generated during cutting, preventing workpiece distortion and tool damage.

- Lubrication: Coolant lubricates the cutting tool and workpiece, reducing friction and extending tool life.

- Chip removal: Coolant flushes away metal chips from the cutting zone, improving surface finish and preventing clogging.

5. How do you troubleshoot common problems encountered during lathe operations?

Common problems include:

Tool Wear

- Inspect the tool for damage or dullness.

- Adjust cutting parameters (speed, feed, depth) to reduce wear.

Chatter

- Check the workpiece for proper clamping.

- Adjust cutting parameters or use a different tool holder.

6. What is the importance of maintaining a clean and organized lathe?

- Safety: A clean lathe reduces the risk of accidents, such as slips and falls.

- Efficiency: A well-organized lathe allows for easy access to tools and materials.

- Machine life: Proper maintenance helps prevent damage to the lathe and extends its lifespan.

7. How do you stay updated on the latest lathe technologies and techniques?

- Industry publications: Subscribe to trade magazines and journals.

- Training programs: Attend workshops and seminars offered by manufacturers and training providers.

- Online resources: Utilize websites, forums, and videos to learn about new technologies and best practices.

8. How do you ensure that the parts produced on the lathe meet the required specifications?

To ensure quality control, I follow a rigorous process that includes:

- Detailed drawings and tolerances: Reviewing specifications thoroughly before starting machining.

- Regular in-process inspection: Using measuring tools to verify dimensions and surface finish during machining.

- Final inspection: Conducting a thorough inspection of the finished part against specifications using calipers, micrometers, and other instruments.

9. What is your experience with different types of lathes?

I have experience with a range of lathes, including:

- Manual lathes: Basic lathes requiring manual operation of all functions.

- CNC lathes: Computer-controlled lathes that automate the machining process.

- Turret lathes: Lathes with multiple turrets that hold different cutting tools for efficient operations.

10. What is your biggest strength as a lathe operator?

My biggest strength as a lathe operator is my:

- Precision and attention to detail: I am meticulous in ensuring the accuracy and quality of my work.

- Problem-solving abilities: I can quickly identify and resolve issues that arise during operations.

- Commitment to safety: I maintain a clean and safe work environment and follow all safety regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lathe Operator is a skilled professional responsible for operating and maintaining lathes, which are machines used to shape metal or other materials by rotating them against a cutting tool.

1. Machine Operation

The primary responsibility of a Lathe Operator is to safely and efficiently operate various lathe machines.

- Setting up and running lathes according to specifications

- Monitoring the cutting process to ensure accuracy and quality

- Making adjustments to the lathe’s speed, feed, and depth of cut

2. Material Preparation

Lathe Operators are also responsible for preparing the materials to be machined.

- Selecting and cutting raw materials to appropriate sizes

- Cleaning and inspecting materials to ensure they are free of defects

- Storing materials properly to prevent damage

3. Quality Control

Lathe Operators are responsible for ensuring the quality of the finished products.

- Inspecting workpieces for accuracy and conformance to specifications

- Using measuring tools and gauges to ensure precision

- Identifying and correcting any defects or errors

4. Machine Maintenance

In addition to operating and monitoring lathes, Lathe Operators are also responsible for basic machine maintenance.

- Lubricating and cleaning lathes to prevent breakdowns

- Replacing worn or damaged parts

- Inspecting and repairing safety features

Interview Tips

Preparing thoroughly for a Lathe Operator interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company

Research the company thoroughly before the interview. This will give you a good understanding of their products, services, and culture.

- Visit the company’s website

- Read news articles and company updates

- Check out the company’s social media pages

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the actual interview.

- Use the STAR method to structure your answers

- Be specific and provide examples

- Relate your answers to the job requirements

3. Highlight Your Skills

In the interview, be sure to highlight your skills and experience that are relevant to the Lathe Operator position.

- Emphasize your experience operating lathes

- Discuss your knowledge of lathe safety

- Mention any experience you have with quality control

4. Ask Questions

At the end of the interview, be sure to ask questions. This shows the interviewer that you are interested in the position and the company.

- Ask about the company’s culture

- Inquire about the training and development opportunities

- Ask about the company’s growth plans

Next Step:

Now that you’re armed with the knowledge of Lathe Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lathe Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini