Are you gearing up for an interview for a Lathe Set Up Person position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lathe Set Up Person and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

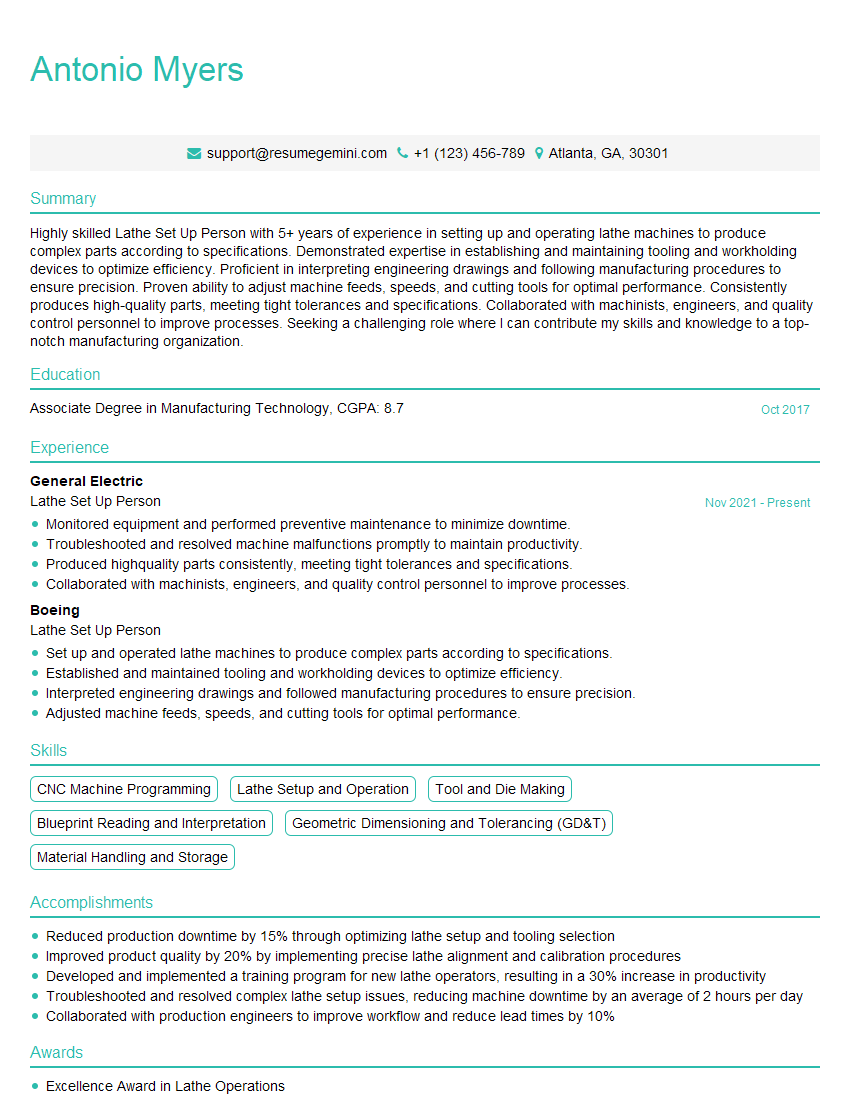

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lathe Set Up Person

1. What is the procedure for setting up a lathe machine?

The procedure for setting up a lathe machine involves several steps:

- Mount the workpiece securely onto the chuck or faceplate.

- Select the appropriate cutting tool and install it in the tool holder.

- Set the spindle speed and feed rate based on the material and machining operation.

- Adjust the tool offset to ensure the cutting tool engages with the workpiece at the correct depth.

- Align the tailstock and center it with the workpiece to provide support during turning.

- Verify all settings and safety precautions before starting the machining process.

2. How do you calculate the spindle speed for a given cutting operation?

Formula: Spindle Speed (rpm) = (Cutting Speed (fpm) x 12) / (Material Diameter (in))

- Determine the required cutting speed based on the material and machining operation.

- Measure the diameter of the workpiece or material being machined.

- Substitute these values into the formula to calculate the spindle speed in revolutions per minute (rpm).

Example:

- Cutting Speed: 150 fpm

- Material Diameter: 2 inches

- Spindle Speed = (150 x 12) / 2 = 900 rpm

3. What are the different types of lathe tools and their uses?

There are various types of lathe tools, each designed for specific machining operations:

- Turning tools: Used for general turning operations, such as facing, turning, and boring.

- Threading tools: Designed for cutting threads on the workpiece.

- Knurling tools: Create a textured surface on the workpiece.

- Form tools: Used to create complex shapes or profiles on the workpiece.

- Boring bars: Extend the reach of cutting tools to bore holes and make internal cuts.

4. How do you align the tailstock with the lathe spindle?

Aligning the tailstock with the lathe spindle is crucial for accurate machining:

- Loosen the tailstock clamp.

- Insert a precision ground rod or mandrel into the chuck and tailstock.

- Adjust the tailstock until the rod runs true between the centers.

- Tighten the tailstock clamp.

- Check the alignment by rotating the spindle and observing the movement of the rod.

5. What are the common types of lathe chucks and their applications?

Lathe chucks are used to secure the workpiece during machining operations:

- Collet chucks: Hold small-diameter workpieces with precision.

- Three-jaw chucks: Universal chucks that can hold a variety of shapes and sizes.

- Four-jaw chucks: Similar to three-jaw chucks but provide independent jaw movement for irregular workpieces.

- Hydraulic chucks: Use hydraulic pressure to grip the workpiece for high-force applications.

- Magnetic chucks: Hold ferrous workpieces magnetically for grinding and surface finishing operations.

6. How do you perform offset boring on a lathe?

- Mount the workpiece on the chuck or faceplate.

- Set up the boring tool in the tool holder.

- Use a dial indicator to measure the distance between the tool tip and the center of the workpiece.

- Adjust the tool offset in the machine control to compensate for the distance.

- Bore the hole to the desired size and depth.

7. How do you calculate the feed rate for a given machining operation?

Formula: Feed Rate (ipm) = (Cutting Speed (fpm) x Number of Teeth) / (Spindle Speed (rpm)

- Determine the cutting speed based on the material and machining operation.

- Count the number of teeth on the cutting tool.

- Measure the spindle speed in revolutions per minute (rpm).

- Substitute these values into the formula to calculate the feed rate in inches per minute (ipm).

Example:

- Cutting Speed: 150 fpm

- Number of Teeth: 6

- Spindle Speed: 900 rpm

- Feed Rate = (150 x 6) / 900 = 1 ipm

8. What are the safety precautions when operating a lathe machine?

Operating a lathe machine safely is essential to prevent accidents:

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Securely fasten the workpiece and all tools before starting the machine.

- Never stand directly in front of the chuck or rotating workpiece.

- Use proper cutting speeds and feed rates to avoid overheating or tool breakage.

- Remain alert and pay attention to the machine’s operation.

- Keep the work area clean and free of debris.

9. How do you troubleshoot common lathe problems, such as chatter or tool breakage?

Chatter or tool breakage during lathe operations can be caused by various factors:

- Chatter:

- Check the workpiece and tool for proper mounting and alignment.

- Reduce the cutting speed or feed rate.

- Use a vibration-damping tool holder.

- Tool breakage:

- Inspect the tool for excessive wear or damage.

- Adjust the cutting speed or feed rate to within the recommended range.

- Use a tool with the correct geometry and material for the machining operation.

10. How do you maintain a lathe machine to ensure its accuracy and longevity?

Regular maintenance is crucial for maintaining the accuracy and longevity of a lathe machine:

- Clean and lubricate all moving parts and components.

- Inspect and replace worn or damaged parts, such as bearings and belts.

- Calibrate the machine regularly to ensure its accuracy and precision.

- Follow the manufacturer’s recommended maintenance schedule.

- Keep the work area organized and free of debris.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lathe Set Up Person.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lathe Set Up Person‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lathe Set Up Person, who is also known as a Machine Set-Up Operator, plays a crucial role in the manufacturing process by ensuring that production equipment operates efficiently and safely. Their main responsibility is to prepare and set up lathes, which are machines used for shaping and cutting metal. Let’s delve into the key job responsibilities of a Lathe Set Up Person.

1. Machine Operation

They are responsible for operating and maintaining lathes, ensuring that they are running smoothly and efficiently. This involves setting up and adjusting the machine, loading and unloading workpieces, and monitoring the machining process to ensure accuracy and precision.

- Loading and unloading workpieces onto the lathe.

- Selecting and installing appropriate cutting tools.

- Setting machine speeds and feeds.

- Monitoring the machining process to ensure accuracy and safety.

2. Machine Setup and Calibration

They are responsible for setting up and calibrating lathes according to the specifications of the manufacturing process. This involves installing tooling, setting machine parameters, and ensuring that the machine is operating within the specified tolerances.

- Installing and aligning tooling on the lathe.

- Setting and adjusting machine parameters, such as speed, feed, and depth of cut.

- Calibrating the machine to ensure accuracy and consistency.

3. Machine Maintenance

They are responsible for performing basic maintenance tasks on lathes to ensure that they are operating properly and safely. This involves cleaning and lubricating machines, changing cutting tools, and identifying and troubleshooting minor issues.

- Cleaning and lubricating the lathe.

- Changing cutting tools as needed.

- Identifying and troubleshooting minor machine issues.

4. Quality Control

They are responsible for conducting quality control checks on finished workpieces to ensure that they meet the required specifications. This involves measuring and inspecting workpieces to ensure accuracy and adherence to the design.

- Inspecting finished workpieces for accuracy and quality.

- Measuring workpieces to ensure they meet specifications.

- Reporting any quality issues to supervisors.

Interview Tips

Securing the job of a Lathe Set Up Person requires strong technical skills and a professional demeanor. Here are some interview tips to help you ace the interview and land your dream job:

1. Research the Company and Position

Thoroughly research the company and the specific position you are applying for. This will help you understand their business, industry, and the specific responsibilities of the role. Understanding the company’s culture and values will also enable you to align your skills and experience with their requirements.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay updated on the latest trends.

- Prepare questions to ask the interviewer that demonstrate your interest and knowledge.

2. Highlight Your Technical Skills and Experience

Emphasize your technical skills and experience in lathe setup and operation. Quantify your accomplishments whenever possible, using specific examples to illustrate your abilities. If you have experience with different types of lathes or have worked with complex materials, be sure to mention that as well.

- Showcase your expertise in machine setup, calibration, and maintenance.

- Provide examples of how you have improved efficiency or reduced downtime.

- Discuss your experience in working with different materials and meeting tight tolerances.

3. Demonstrate Your Commitment to Safety and Quality

Lathe operation involves working with heavy machinery and sharp tools, so it is essential to emphasize your commitment to safety. Highlight any training or certifications you have in safety protocols and accident prevention. Additionally, demonstrate your understanding of quality control processes and your dedication to producing high-quality work.

- Discuss your safety practices and adherence to safety regulations.

- Describe your experience in quality control and inspection.

- Explain how you prioritize accuracy and precision in your work.

4. Practice Common Interview Questions

Prepare for common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in a clear and concise manner, focusing on your relevant skills and experience. You can also prepare questions to ask the interviewer, which shows your interest and engagement.

- Practice answering questions about your experience, skills, and qualifications.

- Be prepared to discuss your strengths and weaknesses.

- Prepare questions to ask the interviewer about the company and the position.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. Punctuality demonstrates respect for the interviewer’s time and conveys your professionalism. Appropriate attire for an interview in a manufacturing environment may include clean, pressed work clothes or business casual attire.

- Dress appropriately for the company culture and industry.

- Be punctual and arrive at the interview location on time.

- Maintain good posture and make eye contact during the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lathe Set Up Person, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lathe Set Up Person positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.