Feeling lost in a sea of interview questions? Landed that dream interview for Lathe Spotter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lathe Spotter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

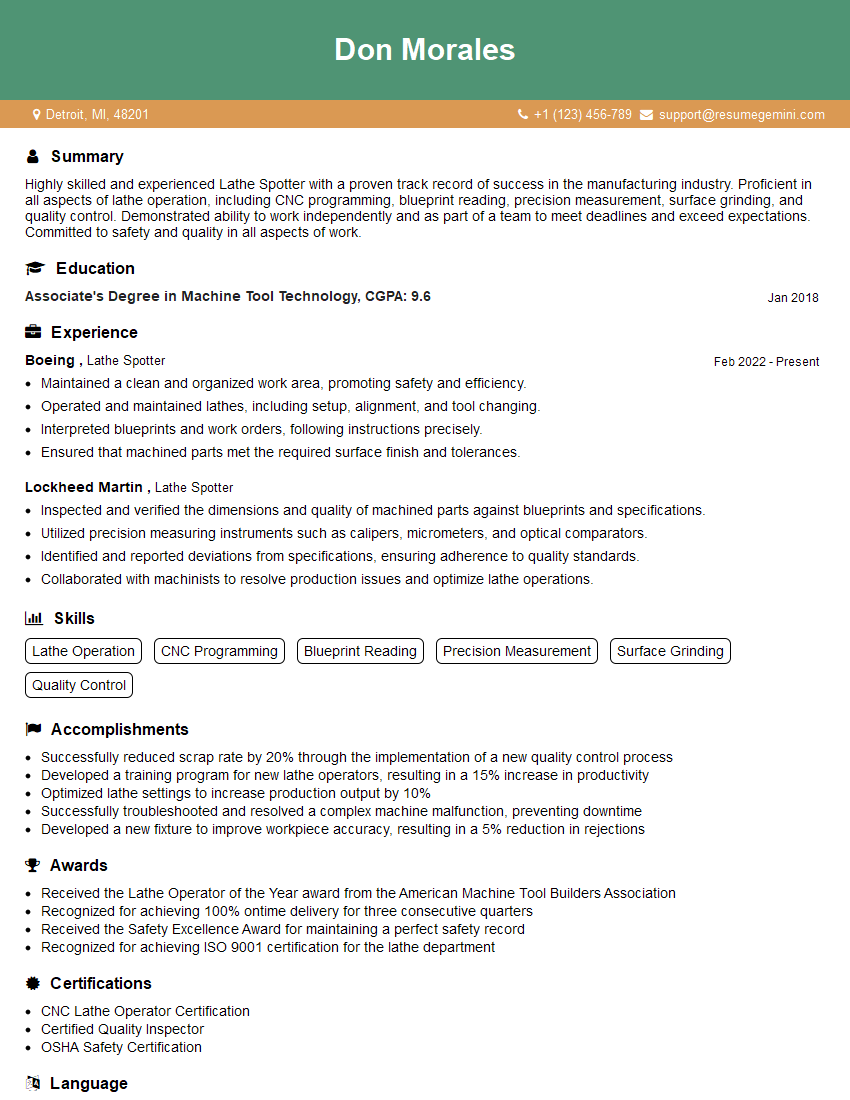

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lathe Spotter

1. What are the different types of lathes?

- Engine lathe

- Turret lathe

- CNC lathe

- Vertical lathe

- Gap lathe

2. What are the different operations that can be performed on a lathe?

Turning

- Straight turning

- Taper turning

- Facing

- Boring

- Knurling

Threading

- Internal threading

- External threading

- Single-point threading

- Multi-point threading

3. What are the different cutting tools used on a lathe?

- Turning tools

- Facing tools

- Boring tools

- Knurling tools

- Threading tools

4. What are the different types of materials that can be machined on a lathe?

- Metals

- Plastics

- Wood

- Composite materials

5. What are the safety precautions that must be taken when operating a lathe?

- Wear appropriate safety gear, including safety glasses, gloves, and a lab coat.

- Keep the work area clean and free of debris.

- Secure the workpiece properly before starting the lathe.

- Use sharp cutting tools and replace them as needed.

- Never reach over or around the rotating workpiece.

- Stop the lathe before making any adjustments or measurements.

- Be aware of the location of the emergency stop button.

6. What are the different types of lathe accessories?

- Chucks

- Faceplates

- Centers

- Tailstocks

- Carriage stops

- Tool holders

- Boring bars

- Knurling tools

- Threading tools

7. What are the different types of lathe operations?

- Turning

- Facing

- Boring

- Knurling

- Threading

- Taper turning

- Form turning

- Grooving

- Parting

8. What are the different types of lathe machines?

- Engine lathes

- Turret lathes

- CNC lathes

- Vertical lathes

- Gap lathes

- Swiss lathes

- Automatic lathes

9. What are the different types of lathe tools?

- Turning tools

- Facing tools

- Boring tools

- Knurling tools

- Threading tools

- Taper turning tools

- Form turning tools

- Grooving tools

- Parting tools

10. What are the different types of lathe materials?

- Metals

- Plastics

- Wood

- Composite materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lathe Spotter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lathe Spotter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lathe Spotter inspects and measures newly machined metal parts using calipers, micrometers, and other equipment to ensure that they meet specifications. They also identify and report any defects or discrepancies.

1. Lathing Process

Involves operating a lathe machine to shape metal and other materials.

- Loading and unloading metal stock into the machine

- Setting up and adjusting the machine’s cutting tools

2. Inspection and Measurement

Involves inspecting and measuring machined parts to ensure that they meet the required specifications.

- Using calipers, micrometers, and other measuring tools to check the dimensions and tolerances of parts

- Identifying and reporting any defects or discrepancies in parts

3. Quality Control

Involves maintaining the quality of machined parts.

- Ensuring that parts meet the required specifications

- Identifying and correcting any quality issues

4. Reporting and Documentation

Involves recording and reporting inspection results and other relevant information.

- Preparing inspection reports and other documentation

- Maintaining records of inspection results

Interview Tips

Preparing for a job interview can be a nerve-wracking experience, but it doesn’t have to be. By following these tips, you can increase your chances of success and land the Lathe Spotter job you’re after.

1. Research the Company and the Role

Take some time to learn about the company you’re applying to and the specific Lathe Spotter role. This will help you understand the company’s culture and values and what they’re looking for in a Lathe Spotter.

- Visit the company’s website

- Read industry news and articles

- Talk to people in your network who work in the industry

2. Practice Your Answers to Common Interview Questions

There are certain questions that are commonly asked in Lathe Spotter interviews. By practicing your answers to these questions ahead of time, you’ll be able to deliver confident and well-thought-out responses.

- Tell me about your experience in the lathe spotting industry

- What are your strengths and weaknesses as a Lathe Spotter

- Why are you interested in this specific Lathe Spotter role

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills as a Lathe Spotter. Be prepared to discuss your experience in detail, including your responsibilities and accomplishments. You should also be able to articulate your skills in lathe spotting, such as your ability to inspect and measure parts to precise tolerances.

- Highlight your experience in operating lathe machines

- Discuss your skills in inspection and measurement

- Mention any experience you have in quality control

4. Ask Questions of the Interviewer

Asking questions of the interviewer is a great way to show that you’re interested in the job and the company. It also gives you an opportunity to learn more about the role and the company culture. Some good questions to ask include:

- What are the biggest challenges facing the company right now

- What are the opportunities for advancement within the company

- What is the company culture like

5. Follow Up After the Interview

After the interview, be sure to follow up with the interviewer. This is a simple way to show your interest in the job and to thank the interviewer for their time. You can follow up by email or by phone.

- Thank the interviewer for their time

- Reiterate your interest in the job

- Ask if there’s anything else you can provide

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lathe Spotter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lathe Spotter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.