Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lathe Turner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

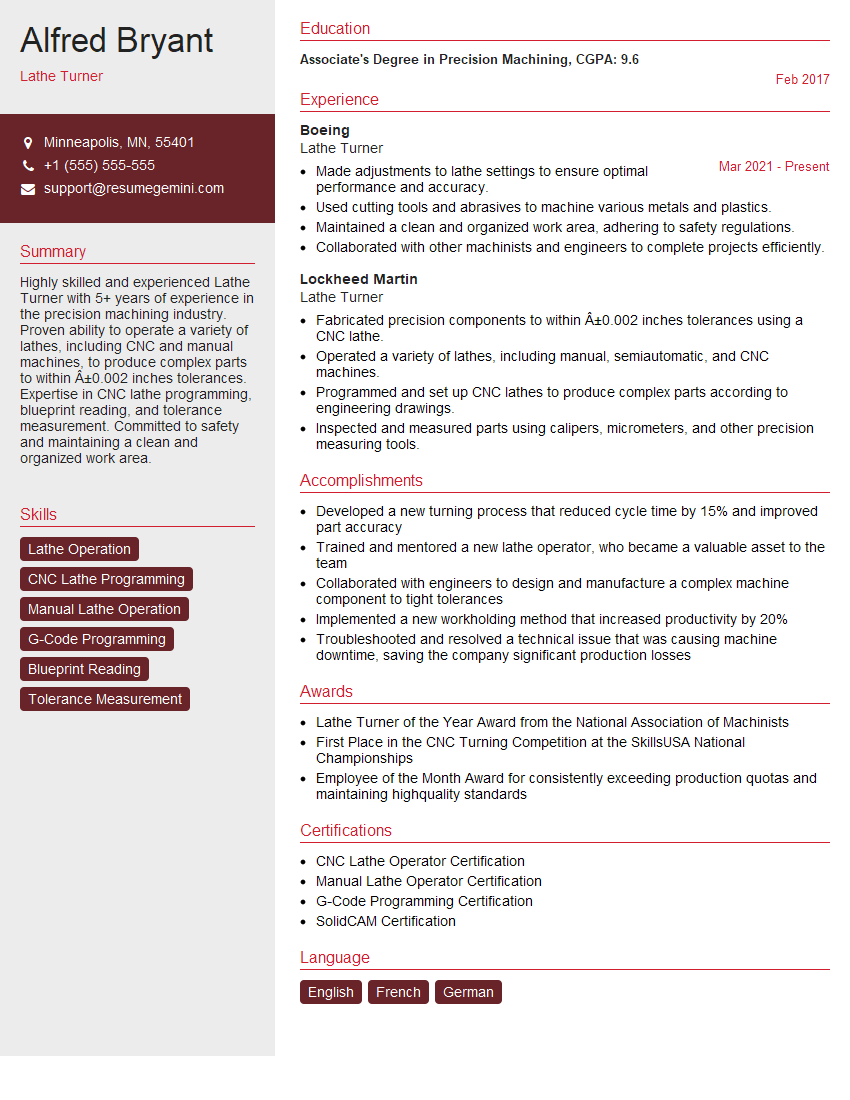

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lathe Turner

1. Explain the process of setting up a lathe machine for turning operations?

- Clean the machine bed and chuck.

- Mount the workpiece in the chuck.

- Select the appropriate cutting tool and secure it in the tool post.

- Set the spindle speed and feed rate.

- Adjust the cutting depth.

- Start the machine and engage the cutting tool.

2. What are the different types of lathe tools and their uses?

HSS Tools

- Turning tools: Used for general turning operations.

- Boring tools: Used for boring holes.

- Facing tools: Used for facing surfaces.

Carbide Tools

- Turning tools: Used for high-speed turning operations.

- Boring tools: Used for boring holes at high speeds.

- Facing tools: Used for facing surfaces at high speeds.

3. How do you measure and adjust the workpiece diameter using a micrometer?

Clean the micrometer faces.

- Close the micrometer and set the zero point.

- Place the workpiece between the micrometer faces.

- Gently tighten the thimble until the micrometer faces just touch the workpiece.

- Read the micrometer scale to determine the workpiece diameter.

If the workpiece diameter is not within tolerance, adjust the cutting tool or workpiece setup accordingly.

4. What are the common causes of chatter during turning operations?

- Incorrect cutting tool geometry.

- Excessive cutting depth.

- Loose or worn workpiece setup.

- Unbalanced workpiece.

- Worn or damaged lathe spindle.

5. How do you calculate the cutting speed and feed rate for a given material and cutting tool?

- Determine the material cutting speed (in feet per minute) based on the material hardness and cutting tool type.

- Calculate the spindle speed (in revolutions per minute) based on the cutting speed and workpiece diameter.

- Determine the feed rate (in inches per revolution) based on the material hardness and cutting tool type.

6. What are the safety precautions that must be followed when operating a lathe machine?

- Wear appropriate safety gear, including eye protection, gloves, and hearing protection.

- Tie back long hair and loose clothing.

- Keep the work area clean and free of debris.

- Never operate the machine with the chuck guard open.

- Do not attempt to stop the machine by hand.

7. Describe the different types of lathe chucks and their applications?

- 3-jaw chuck: Used for holding round workpieces.

- 4-jaw chuck: Used for holding square, hexagonal, or irregularly shaped workpieces.

- Collet chuck: Used for holding small, delicate workpieces.

8. What are the different types of lathe operations?

- Turning: Removing material from a workpiece to create a cylindrical shape.

- Boring: Creating holes in a workpiece.

- Facing: Creating flat surfaces on a workpiece.

- Threading: Creating threads on a workpiece.

- Knurling: Creating a textured surface on a workpiece.

9. What are the advantages of using a CNC lathe over a manual lathe?

- Increased accuracy and precision.

- Reduced setup time.

- Increased production rates.

- Reduced operator fatigue.

10. What are the career advancement opportunities for a Lathe Turner?

- CNC Lathe Operator

- Lathe Programmer

- Machinist

- Supervisor

- Manager

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lathe Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lathe Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Lathe Turner

Lathe Turners are skilled machinists who operate lathes to shape and cut metal parts. They play a crucial role in various industries, including manufacturing, automotive, and aerospace.

1. Machine Operation

Operate lathes to perform various machining tasks, such as turning, drilling, boring, and threading.

- Follow blueprints and specifications to determine the required cuts and dimensions.

- Select and install appropriate cutting tools.

2. Material Preparation and Setup

Prepare raw materials (e.g., metal rods, bars) for machining.

- Cut materials to the desired length.

- Mount materials securely in the lathe.

3. Machining Processes

Perform machining operations to create precise parts.

- Turn parts to reduce diameter and create cylindrical shapes.

- Drill holes and bore cylindrical cavities.

- Thread parts to create external or internal threads.

4. Quality Control and Inspection

Inspect machined parts to ensure conformity to specifications.

- Use precision measuring tools (e.g., micrometers, calipers) to verify dimensions.

- Identify and rectify any deviations or defects.

5. Maintenance and Troubleshooting

Maintain and troubleshoot lathes to ensure optimal performance.

- Lubricate and clean lathes regularly.

- Identify and resolve mechanical or electrical problems.

Interview Preparation Tips for a Lathe Turner

Preparing thoroughly for your interview is crucial to showcasing your skills and qualifications for the Lathe Turner position. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Research the company and the industry to understand their business, culture, and market position. This will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about trends.

2. Practice Your Skills

Refresh your knowledge of lathe operations and practices. Consider practicing on your own or taking a refresher course to enhance your confidence.

- Review the fundamentals of lathe turning, such as cutting speeds, feeds, and tool geometry.

- Practice setting up and operating lathes, using different materials and cutting tools.

3. Prepare for Technical Questions

Expect technical questions related to lathe turning and machining processes. Be prepared to discuss your experience, expertise, and problem-solving abilities.

- Think about projects or tasks where you demonstrated exceptional lathe turning skills.

- Prepare to explain how you would approach specific machining challenges or scenarios.

4. Highlight Your Safety and Attention to Detail

Lathe turning involves working with sharp tools and machinery. Emphasize your commitment to safety and attention to detail to ensure accurate and meticulous work.

- Discuss your safety practices and any safety certifications you hold.

- Provide examples of how you have ensured high-quality and precision in your previous roles.

5. Be Enthusiastic and Confident

Convey your passion for lathe turning and your eagerness to contribute to the team. Demonstrate your confidence in your abilities and your willingness to learn and improve.

- Articulate your reasons for seeking the position and how your skills align with the company’s requirements.

- Ask insightful questions about the role and the company to show your engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lathe Turner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!