Are you gearing up for an interview for a Lathe Winder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lathe Winder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

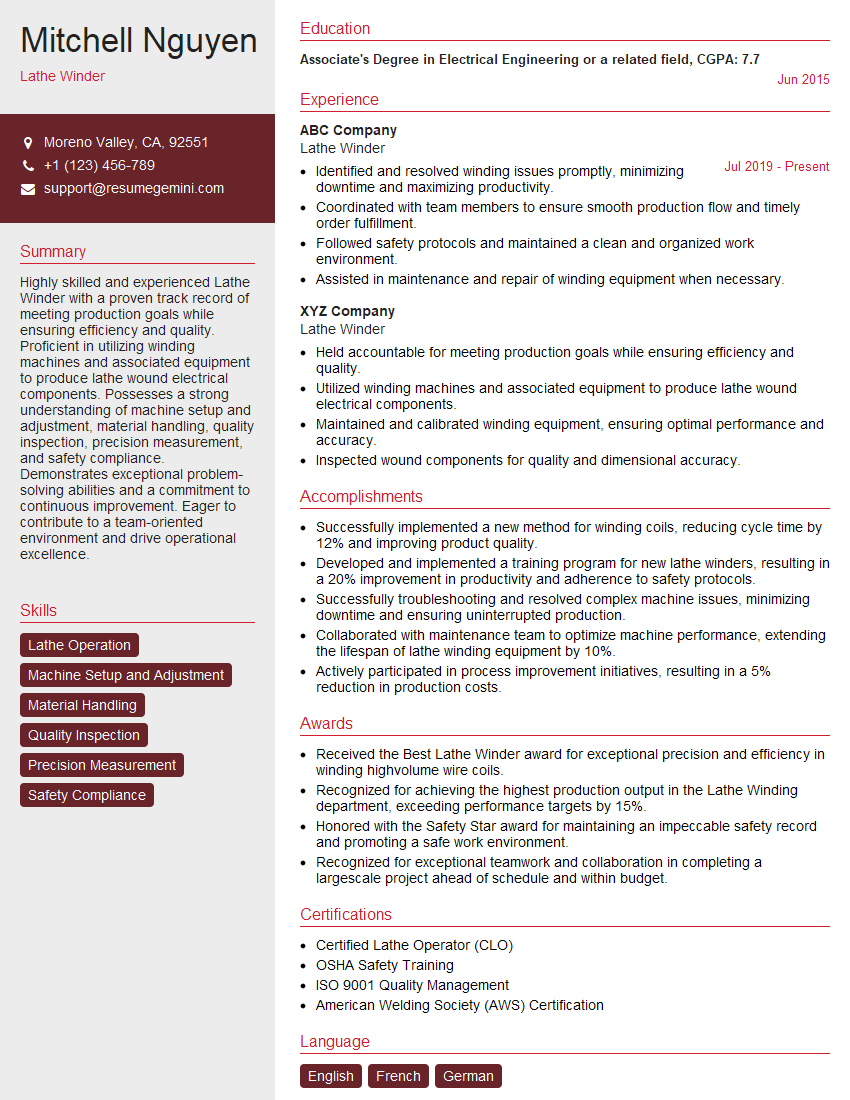

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lathe Winder

1. Explain the process of setting up and operating a lathe winding machine?

To set up and operate a lathe winding machine, I follow these steps:

- Select and install the appropriate winding head and tooling for the job.

- Load the wire onto the machine and thread it through the guides.

- Set the winding parameters, such as the speed, tension, and number of turns.

- Start the winding process and monitor it closely.

- Make adjustments to the winding parameters as needed to ensure the desired results.

- Once the winding process is complete, remove the finished coil from the machine.

2. Describe the different types of wire used in lathe winding and their applications?

Conductors

- Copper: High conductivity, suitable for most applications.

- Aluminum: Lighter and less expensive but less conductive.

- Silver: Highest conductivity but most expensive.

Insulators

- Polyester: Excellent electrical insulation, high temperature resistance.

- Nomex: High temperature resistance, used in aerospace applications.

- Kapton: High temperature resistance, chemical resistance.

3. Explain the importance of maintaining proper tension during the winding process?

- Ensures uniform winding and prevents wire breakage.

- Optimizes electrical performance by maintaining the proper spacing between turns.

- Reduces the risk of insulation damage and short circuits.

- Improves the overall quality and reliability of the wound coil.

4. Describe the troubleshooting techniques used to identify and resolve common lathe winding problems?

- Wire breakage: Check tension settings, wire quality, and guides for damage.

- Uneven winding: Adjust tension settings, check for misaligned guides.

- Short circuits: Use continuity tester to locate the short, check insulation for damage.

- Open circuits: Use continuity tester to locate the break, check connections and wire integrity.

- Overheating: Check current settings, ensure proper ventilation, inspect for binding.

5. Explain the safety precautions that must be followed when working with a lathe winding machine?

- Wear appropriate PPE, including safety glasses, gloves, and hearing protection.

- Keep the work area clean and free of debris.

- Never operate the machine with loose clothing or jewelry.

- Be aware of the location of the emergency stop button.

- Follow all manufacturer’s instructions and guidelines for safe operation.

6. Describe the importance of quality control in lathe winding?

- Ensures the coils meet the required specifications.

- Prevents defects and failures that could lead to equipment damage or safety hazards.

- Maintains the reputation of the company and its products.

- Reduces production costs by minimizing rework and scrap.

7. Explain the different types of lathe winding machines and their capabilities?

Manual Lathe Winding Machines

- Require manual operation, less expensive.

- Suitable for low-volume production or prototyping.

Semi-Automatic Lathe Winding Machines

- Combine manual and automated operations, increase efficiency.

- Used for medium-volume production.

Fully Automatic Lathe Winding Machines

- Fully automated, high speed and accuracy.

- Suitable for high-volume production.

8. Describe the role of computer-aided design (CAD) in lathe winding?

- Creates precise winding patterns and programs for the winding machine.

- Optimizes winding parameters for efficiency and quality.

- Reduces setup time and improves consistency.

- Facilitates communication with customers and engineers.

9. Explain the importance of preventive maintenance for lathe winding machines?

- Extends the life of the machine.

- Reduces downtime and maintenance costs.

- Improves safety and reliability.

- Maintains optimal performance and accuracy.

10. Describe the career path and advancement opportunities for lathe winders?

- Senior Lathe Winder: Supervises and trains other winders.

- Quality Control Inspector: Ensures the quality of wound coils.

- Process Engineer: Improves winding processes and develops new techniques.

- Manager: Oversees the winding department and manages operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lathe Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lathe Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lathe Winders play a vital role in manufacturing by operating lathe machines to wind coils and transformers. They ensure the smooth functioning of production lines by monitoring and maintaining equipment, optimizing processes, and ensuring quality standards are met.

1. Machine Operation

Lathe Winders are responsible for operating and maintaining lathe machines.

- Setting up and operating lathes to wind coils and transformers

- Monitoring machine operations and making adjustments to ensure optimal performance

- Maintaining and troubleshooting machines to prevent breakdowns and ensure smooth production

2. Quality Control

Lathe Winders are responsible for ensuring the quality of the coils and transformers they produce.

- Inspecting coils and transformers for defects and ensuring they meet specifications

- Testing coils and transformers to verify their electrical and mechanical properties

- Maintaining records of quality checks and reporting any issues to supervisors

3. Production Optimization

Lathe Winders are responsible for optimizing production processes to improve efficiency and minimize waste.

- Identifying and implementing process improvements to increase productivity

- Working with engineers and other production staff to develop and implement new winding techniques

- Training and mentoring new employees to ensure they follow established processes and procedures

4. Safety and Compliance

Lathe Winders are responsible for maintaining a safe and compliant work environment.

- Following all safety regulations and procedures

- Wearing appropriate personal protective equipment

- Reporting any safety hazards or concerns to supervisors and taking necessary corrective actions

Interview Tips

Preparing for a Lathe Winder interview requires a combination of technical knowledge and an understanding of the industry. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, take some time to research the company you’re applying to and the specific Lathe Winder position. This will help you understand the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website and read about their mission, products, and services.

- Look up the job description and make note of the key responsibilities and qualifications.

- If possible, connect with current or former employees on LinkedIn to learn more about the company and the role.

2. Highlight Your Technical Skills and Experience

During the interview, be sure to highlight your technical skills and experience as a Lathe Winder. This includes your ability to operate and maintain lathe machines, your knowledge of quality control procedures, and your experience in optimizing production processes.

- Quantify your accomplishments using specific examples and data whenever possible.

- Be prepared to discuss your experience with different types of lathe machines and winding techniques.

- Emphasize your ability to troubleshoot and solve problems independently.

3. Demonstrate Your Commitment to Safety and Compliance

Safety is paramount in manufacturing environments. In your interview, be sure to demonstrate your commitment to safety and compliance.

- Highlight your knowledge of industry safety regulations and your experience in following safety procedures.

- Describe your experience in identifying and mitigating safety hazards.

- Explain how you stay up-to-date on the latest safety best practices.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. It’s also an opportunity to learn more about the company and the role.

- Ask about the company’s growth plans and how the Lathe Winder position fits into those plans.

- Inquire about the company’s commitment to training and development.

- Ask about the company’s safety culture and how they ensure a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lathe Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!