Are you gearing up for a career in Lay-Ups Assembler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lay-Ups Assembler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

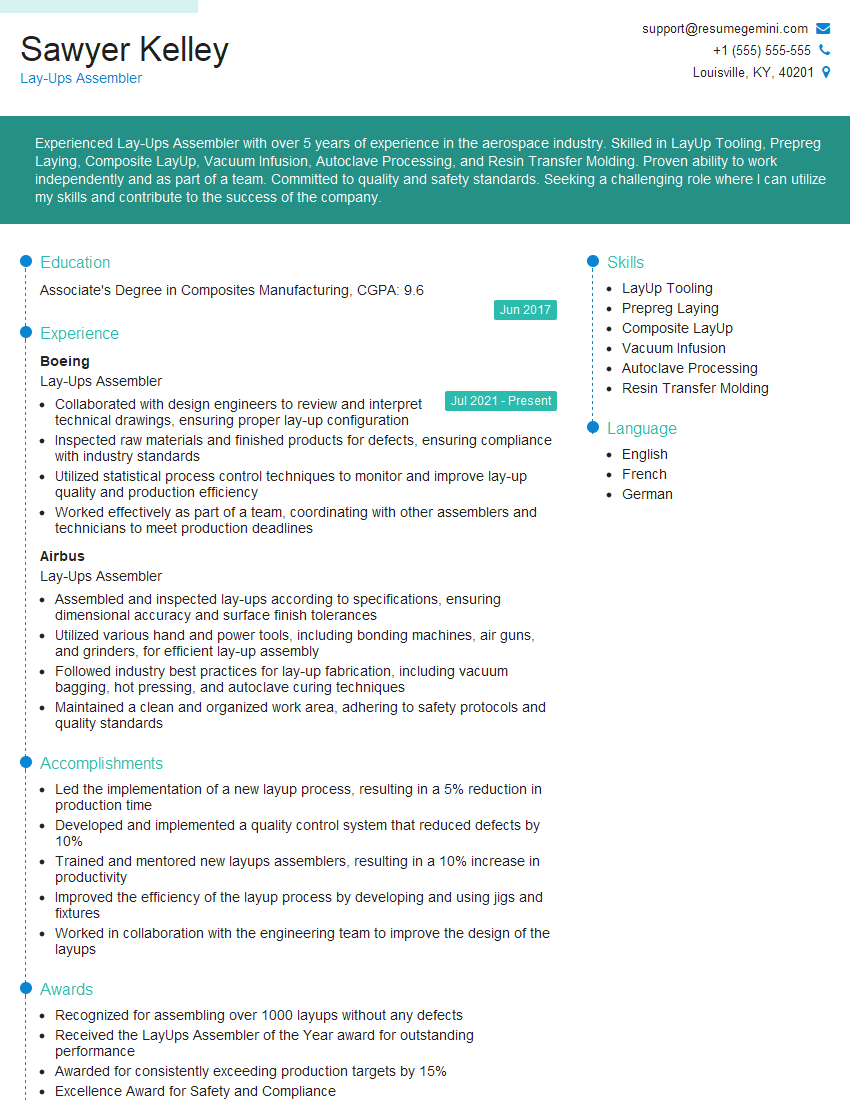

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lay-Ups Assembler

1. Describe the types of lay-ups you have experience with?

I have experience with several types of lay-ups, including hand lay-up, spray lay-up, and vacuum bagging. Each technique requires specialized knowledge and skills. For example, hand lay-up involves manually applying resin and reinforcement materials to a mold, while spray lay-up uses a spray gun to apply resin and reinforcement materials.

2. What are the key steps involved in lay-up assembly?

Materials Preparation

- Selecting and preparing the appropriate materials, including resin, reinforcement fabrics, mold release agents, and curing agents.

Mold Preparation

- Cleaning and preparing the mold to ensure proper surface finish and adhesion.

Laminate Construction

- Applying alternating layers of resin and reinforcement fabrics onto the mold, ensuring proper orientation and thickness.

Curing

- Allowing the laminate to cure through a controlled process involving temperature, pressure, and time.

Demolding

- Removing the cured part from the mold once it has reached its desired properties.

Post-Processing

- Performing any necessary post-processing steps, such as trimming, sanding, or painting.

3. How do you ensure the quality of your lay-ups?

I follow a stringent quality control process to ensure the quality of my lay-ups. This includes:

- Thoroughly inspecting raw materials for defects.

- Verifying that the mold is clean and free from contaminants.

- Meticulously applying resin and reinforcement materials according to specifications.

- Monitoring curing conditions to achieve optimal properties.

- Conducting non-destructive testing to identify any anomalies or imperfections.

- Maintaining detailed records of all production parameters and test results.

4. What safety precautions do you observe when working with lay-up materials?

I prioritize safety in my work environment by adhering to the following precautions:

- Wearing appropriate personal protective equipment, including gloves, respirators, and protective clothing.

- Handling hazardous materials with care, ensuring proper storage and disposal.

- Maintaining a clean and organized work area to minimize tripping or slipping hazards.

- Being aware of potential fire hazards and having appropriate fire extinguishers nearby.

- Following established safety protocols and emergency procedures.

5. How do you stay updated with the latest advancements in lay-up techniques?

I am committed to continuous learning and staying abreast of the latest advancements in lay-up techniques. I achieve this through:

- Attending industry conferences, workshops, and training programs.

- Reading technical journals and research papers.

- Consulting with experts and peers in the field.

- Experimenting with new materials and processes to improve efficiency and product quality.

6. Can you describe a particularly challenging lay-up project you have worked on? How did you overcome the challenges?

In a recent project, I encountered a challenging lay-up involving a complex geometry with tight tolerances. To overcome these challenges:

- I carefully planned the lay-up sequence and material selection to minimize distortion.

- I employed specialized tooling and techniques to achieve the required precision.

- I conducted ongoing measurements and adjustments throughout the process to ensure dimensional accuracy.

- I implemented a rigorous quality control system to detect and correct any potential defects.

7. What is the difference between a prepreg lay-up and a wet lay-up?

Prepreg Lay-up:

- Uses pre-impregnated reinforcement materials with resin.

- Offers higher fiber content and improved mechanical properties.

- Requires specialized equipment and controlled curing conditions.

Wet Lay-up:

- Involves applying dry reinforcement materials and then saturating them with liquid resin.

- More versatile and cost-effective for smaller-scale projects.

- Requires careful resin application and curing to achieve optimal results.

8. How do you calculate the resin-to-fiber ratio in a lay-up?

The resin-to-fiber ratio is determined by the weight of resin used compared to the weight of reinforcement fibers. To calculate it:

- Weigh the reinforcement materials before and after applying the resin.

- Subtract the initial weight from the final weight to obtain the weight of the resin.

- Divide the weight of the resin by the weight of the reinforcement fibers to get the resin-to-fiber ratio.

9. What are the common defects that can occur in lay-ups and how do you prevent them?

Common Defects:

- Voids: Caused by trapped air or insufficient resin penetration – Prevented by thorough vacuum degassing and proper resin application.

- Wrinkles: Result from excessive fabric tension – Prevented by carefully controlling fabric tension and using appropriate tooling.

- Delamination: Occurs when layers separate – Prevented by ensuring proper surface preparation and adhesion between layers.

- Fiber waviness: Caused by improper fiber alignment – Prevented by using high-quality reinforcement materials and maintaining consistent tension during lay-up.

10. How do you determine the optimal curing parameters for a lay-up?

The optimal curing parameters depend on the specific resin and reinforcement materials used. To determine them:

- Refer to the manufacturer’s recommendations for curing temperature and time.

- Conduct trial runs to evaluate the effects of different curing conditions on the final product properties.

- Consider the specific requirements of the end application and the desired performance characteristics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lay-Ups Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lay-Ups Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lay-Ups Assemblers play a vital role in the manufacturing process, assuming key responsibilities such as:

1. Lay-Up of Composite Materials

Performing lay-ups of composite materials, including cutting, placing, and bonding layers of materials to create molds and parts.

2. Ensuring Quality Standards

Adhering to strict quality standards throughout the lay-up process, ensuring the accuracy and integrity of assembled parts.

3. Operating Equipment

Proficiently utilizing equipment such as spray guns, mixers, and ovens for the precise application and curing of materials.

4. Safety Compliance

Maintaining a safe working environment by following established safety protocols and utilizing personal protective equipment.

Interview Tips

To ace the Lay-Ups Assembler interview, candidates should focus on the following preparation tips:

1. Research the Company and Role

Familiarize themselves with the company’s operations, mission, and specific requirements for the position.

2. Practice Answering Common Questions

Prepare answers to typical interview questions about experience, skills, and motivations, using the STAR method to provide specific and concise responses.

Example: “Tell me about a time you had to troubleshoot a complex lay-up issue.”

3. Highlight Relevant Skills and Experience

Emphasize skills and experience in composite materials handling, quality assurance, and equipment operation.

Example: “In my previous role, I was responsible for the lay-up of custom composite parts, ensuring dimensional accuracy and meeting strict quality standards.”

4. Demonstrate Safety Awareness

Convey a strong understanding of safety protocols and a commitment to maintaining a safe work environment.

Example: “I am highly aware of the potential hazards associated with composite materials and regularly follow established safety procedures.”

5. Be Enthusiastic and Presentable

Project a positive attitude and enthusiasm for the role, while maintaining a professional demeanor.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lay-Ups Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.