Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Laydown Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

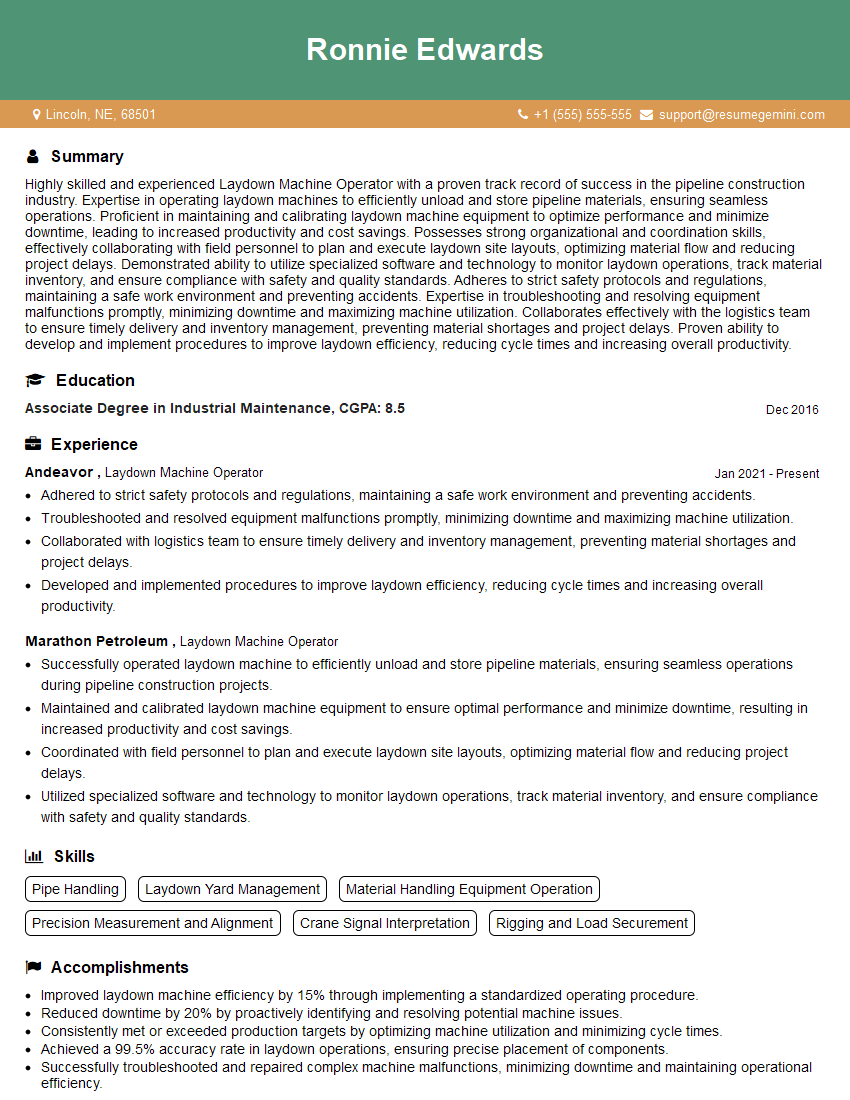

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Laydown Machine Operator

1. What are the key responsibilities of a Laydown Machine Operator?

The key responsibilities of a Laydown Machine Operator include:

- Operate and maintain laydown machines used to assemble and disassemble pipelines

- Ensure that the laydown machine is in good working order and meets all safety requirements

- Follow established procedures and maintain records of all activities

- Work as part of a team to meet production targets

- Troubleshoot and resolve any issues that may arise during the operation of the laydown machine

2. What types of laydown machines have you operated?

I have operated a variety of laydown machines, including:

Horizontal Laydown Machines

- Caterpillar Pipeline Puller

- American Augers Laydown Machine

Vertical Laydown Machines

- Mannesmann Vertical Pipe Handler

- Trenchless Technologies Vertical Stinger

3. What are the safety precautions that must be taken when operating a laydown machine?

The following safety precautions must be taken when operating a laydown machine:

- Always wear appropriate safety gear, including hard hat, safety glasses, and gloves

- Be aware of the surroundings and potential hazards

- Follow established procedures for operating the laydown machine

- Never operate the laydown machine under the influence of alcohol or drugs

- Report any unsafe conditions or equipment malfunctions to a supervisor immediately

4. How do you troubleshoot and resolve common problems with laydown machines?

When troubleshooting and resolving common problems with laydown machines, I follow these steps:

- Identify the problem and its symptoms

- Check for any obvious causes, such as loose connections or damaged components

- Refer to the manufacturer’s troubleshooting guide

- Contact a qualified technician if the problem cannot be resolved

5. How do you maintain a laydown machine to ensure its optimal performance?

To maintain a laydown machine to ensure its optimal performance, I perform the following tasks:

- Regularly clean and inspect the machine

- Lubricate all moving parts

- Check the hydraulic system for leaks

- Inspect the electrical system for loose connections

- Follow the manufacturer’s recommended maintenance schedule

6. What is your experience with using laydown machines in different weather conditions?

I have experience using laydown machines in a variety of weather conditions, including extreme heat, cold, rain, and snow.

- In extreme heat, I take precautions to stay hydrated and avoid overheating the machine

- In cold weather, I warm up the machine before operating it and take breaks to stay warm

- In rain and snow, I use caution to avoid slipping and falling and take steps to protect the machine from the elements

7. How do you work as part of a team to ensure efficient operation of a laydown machine?

When working as part of a team to ensure efficient operation of a laydown machine, I:

- Communicate effectively with other team members

- Follow instructions and take direction from the team leader

- Share knowledge and expertise with other team members

- Help to resolve problems and conflicts

- Maintain a positive and productive work environment

8. What are your strengths and weaknesses as a Laydown Machine Operator?

My strengths as a Laydown Machine Operator include:

- Strong mechanical aptitude

- Ability to troubleshoot and resolve problems

- Experience operating a variety of laydown machines

- Commitment to safety

- Ability to work independently and as part of a team

My weaknesses as a Laydown Machine Operator include:

- Limited experience operating laydown machines in extreme weather conditions

- Need to improve my communication skills

9. What are your career goals?

My career goals are to:

- Become a highly skilled and experienced Laydown Machine Operator

- Work on a variety of challenging and rewarding pipeline projects

- Contribute to the success of my team and company

- Earn a reputation for being a safe and reliable operator

10. Why should we hire you as a Laydown Machine Operator?

You should hire me as a Laydown Machine Operator because I have the skills, experience, and commitment to be a valuable asset to your team.

- I am a highly skilled and experienced Laydown Machine Operator with a proven track record of success

- I am committed to safety and follow all established procedures

- I am a team player and work well with others

- I am eager to learn and grow and I am confident that I can make a significant contribution to your company

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Laydown Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Laydown Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Laydown Machine Operators are responsible for the safe and efficient operation of laydown machines used in construction projects, such as road building and pipeline installation.

1. Machine Operation

The primary responsibility of a Laydown Machine Operator is to operate and control laydown machines, ensuring that they are functioning properly and efficiently.

- Setting up, calibrating, and operating laydown machines in accordance with manufacturers’ instructions.

- Monitoring machine performance and adjusting operating parameters to optimize production and maintain machine health.

2. Material Handling

Laydown Machine Operators are also responsible for handling and loading the materials used in construction projects.

- Receiving and inspecting incoming materials, such as pipe segments, concrete, and asphalt.

- Loading and unloading materials onto and from laydown machines using forklifts or other lifting equipment.

3. Site Management

Laydown Machine Operators may also be involved in site management tasks to ensure the smooth operation of the project.

- Maintaining the laydown area by clearing debris, leveling the ground, and creating drainage systems.

- Coordinating with other workers, such as truck drivers, crane operators, and construction crews, to ensure timely and efficient delivery of materials.

4. Safety and Maintenance

Laydown Machine Operators must prioritize safety and maintain their machines to ensure optimal performance and prevent accidents.

- Following all safety protocols, wearing appropriate personal protective equipment (PPE), and maintaining a clean and organized work environment.

- Performing routine maintenance tasks, such as lubricating moving parts, checking fluid levels, and replacing worn components.

Interview Tips

To ace your interview for a Laydown Machine Operator position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and current projects. Research the specific role and identify the key responsibilities and requirements.

2. Highlight Your Experience and Skills

Emphasize your experience operating laydown machines, handling materials, and maintaining a safe work environment. Quantify your results whenever possible to demonstrate the impact of your contributions.

3. Prepare for Technical Questions

Be ready to answer questions about your understanding of laydown machine operations, safety procedures, and maintenance practices. Consider preparing examples from your past experience that showcase your technical abilities.

4. Demonstrate Your Commitment to Safety

Stress your unwavering commitment to safety and your understanding of the importance of following safety protocols on construction sites.

5. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer about the company, the project, and the role. This shows your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Laydown Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!