Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lead Burner Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lead Burner Helper so you can tailor your answers to impress potential employers.

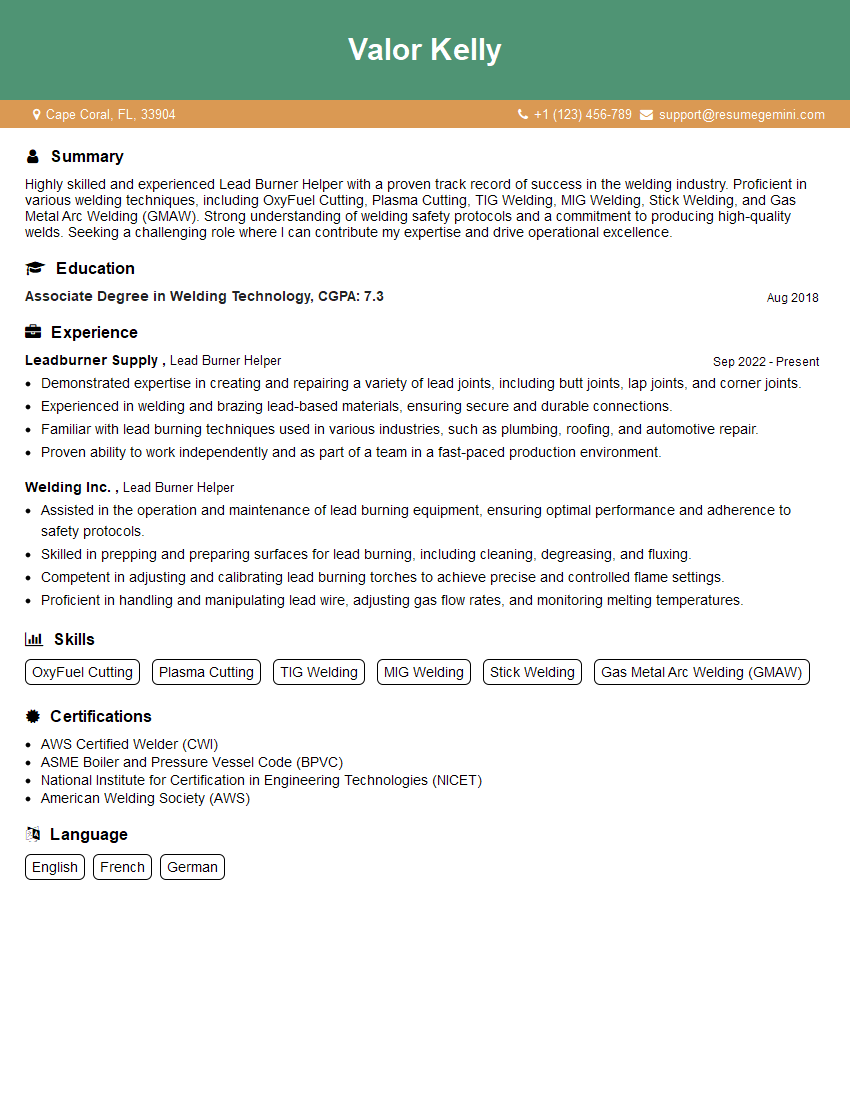

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Burner Helper

1. Describe the main responsibilities of a Lead Burner Helper?

The primary responsibilities of a Lead Burner Helper include:

- Supporting lead burners by providing assistance with setup, operation, and maintenance of lead burning equipment

- Performing various tasks such as mixing fuel gases, preparing lead rods, and cleaning equipment

- Monitoring the lead burning process to ensure safety and quality standards

- Maintaining a clean and organized work area

- Following safety regulations and procedures

2. Explain the importance of proper gas mixture ratio in lead burning?

Safety

- Incorrect gas mixture ratio can lead to explosions or fires

- Ensuring proper ratio is crucial for safety

Quality

- Optimal gas mixture ratio produces strong, durable lead joints

- Improper ratio can result in weak, porous welds

Efficiency

- Correct ratio allows for proper combustion, resulting in efficient lead burning

- Incorrect ratio can lead to wasted fuel and reduced productivity

3. How do you ensure the quality of lead burned joints?

To ensure the quality of lead burned joints, I follow these steps:

- Properly prepare surfaces to be joined, removing any contaminants

- Select appropriate lead rods and flux based on the materials being joined

- Control the temperature and heat input during the lead burning process

- Monitor the molten lead and fill any voids or gaps

- Allow the joint to cool slowly and properly

- Inspect the finished joint for any defects or imperfections

4. Describe the steps involved in preparing a lead burning torch?

To prepare a lead burning torch, I follow these steps:

- Assemble the torch body, mixing chamber, and cutting tip

- Attach the fuel gas and oxygen hoses

- Check for any leaks in the hose connections

- Adjust the gas flow rates to achieve the desired flame

- Ignite the torch and observe the flame for proper combustion

5. How do you maintain lead burning equipment?

To maintain lead burning equipment, I perform regular checks and maintenance tasks:

- Inspect hoses and connections for any leaks or damage

- Clean the torch tip and mixing chamber to prevent clogging

- Replace worn or damaged parts as needed

- Lubricate moving parts to ensure smooth operation

- Store equipment properly in a dry, clean environment

6. Can you explain the techniques used to remove lead from joints?

To remove lead from joints, I use the following techniques:

- Mechanical removal using a chisel and hammer

- Chemical removal using a lead dissolving solution

- Thermal removal using a heat gun or torch

- Electrolytic removal using a specialized electrochemical process

7. What safety precautions should be taken when working with lead?

When working with lead, it is important to follow these safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator

- Ensure proper ventilation to prevent lead fumes from accumulating

- Avoid direct contact with lead and lead-contaminated surfaces

- Maintain good hygiene practices, such as washing hands frequently

- Receive regular medical monitoring for lead exposure

8. How do you deal with lead spills or leaks?

In the event of a lead spill or leak, I take the following steps:

- Contain the spill or leak using absorbent materials

- Ventilate the area to remove lead fumes

- Notify the supervisor and follow established spill response procedures

- Clean and decontaminate the affected area thoroughly

- Dispose of contaminated materials properly

9. Explain the different types of lead burning flames and their applications?

There are three main types of lead burning flames:

Oxidizing Flame

- Excess oxygen in the flame

- Used for removing lead or preheating surfaces

Neutral Flame

- Balanced ratio of fuel gas and oxygen

- Used for general lead burning applications

Reducing Flame

- Excess fuel gas in the flame

- Used for welding or brazing applications

10. What factors affect the speed and quality of lead burning?

The speed and quality of lead burning are influenced by several factors:

- Proper gas mixture ratio

- Torch flame adjustment

- Surface preparation

- Lead rod selection

- Operator skill and experience

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Burner Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Burner Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lead Burner Helper performs a crucial role in the fabrication and repair of metal structures by assisting Lead Burners in a variety of tasks.

1. Assisting with Lead Burning Operations

The Helper aids the Lead Burner by setting up and operating oxyacetylene or oxyfuel torches, regulating gas flow, and maintaining equipment.

- Preparing and cleaning metal surfaces for lead burning.

- Holding welding rods or fluxes during the lead burning process.

2. Material Handling and Preparation

The Helper is responsible for handling and moving heavy metal sheets, beams, and other materials.

- Cutting and preparing metals according to specifications.

- Loading and unloading materials from vehicles and storage areas.

3. Maintenance and Equipment Cleaning

The Helper ensures that equipment is in good working condition and maintains a clean and organized work area.

- Cleaning torches, hoses, and other equipment after use.

- Maintaining inventory of supplies and materials.

4. Safety and Compliance

The Helper follows safety protocols and adheres to all applicable regulations.

- Wearing appropriate personal protective equipment.

- Maintaining a clean and safe work environment.

Interview Tips

Preparing effectively for a Lead Burner Helper interview can significantly increase your chances of success. Here are some valuable tips to consider:

1. Research the Company and Industry

Gain a thorough understanding of the company’s operations, history, and industry trends. This will demonstrate your interest and knowledge of the field.

- Visit the company’s website and read industry publications.

- Attend industry events or connect with professionals on LinkedIn.

2. Emphasize Teamwork and Communication Skills

Lead Burner Helpers often work closely with other team members and supervisors. Highlight your ability to collaborate effectively and communicate clearly.

- Provide examples of projects where you successfully worked as part of a team.

- Demonstrate your ability to follow instructions and ask clarifying questions when needed.

3. Highlight Physical Capabilities

The job involves physical labor and requires candidates to be able to lift heavy materials and withstand demanding work conditions.

- Quantify your physical capabilities, such as the weight you can safely lift.

- Describe any previous experience in physically demanding roles.

4. Prepare for Technical Questions

Interviewers may ask questions about your knowledge of lead burning processes, safety protocols, and equipment handling. Review relevant technical concepts to demonstrate your understanding.

- Familiarize yourself with the different types of lead burning equipment and techniques.

- Study safety regulations related to lead burning and hazardous materials.

5. Prepare for Behavioral Questions

Behavioral questions focus on your past experiences and behaviors. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Describe a situation where you demonstrated strong teamwork skills.

- Explain how you handled a challenging task related to physical labor.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lead Burner Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!