Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lead Burner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

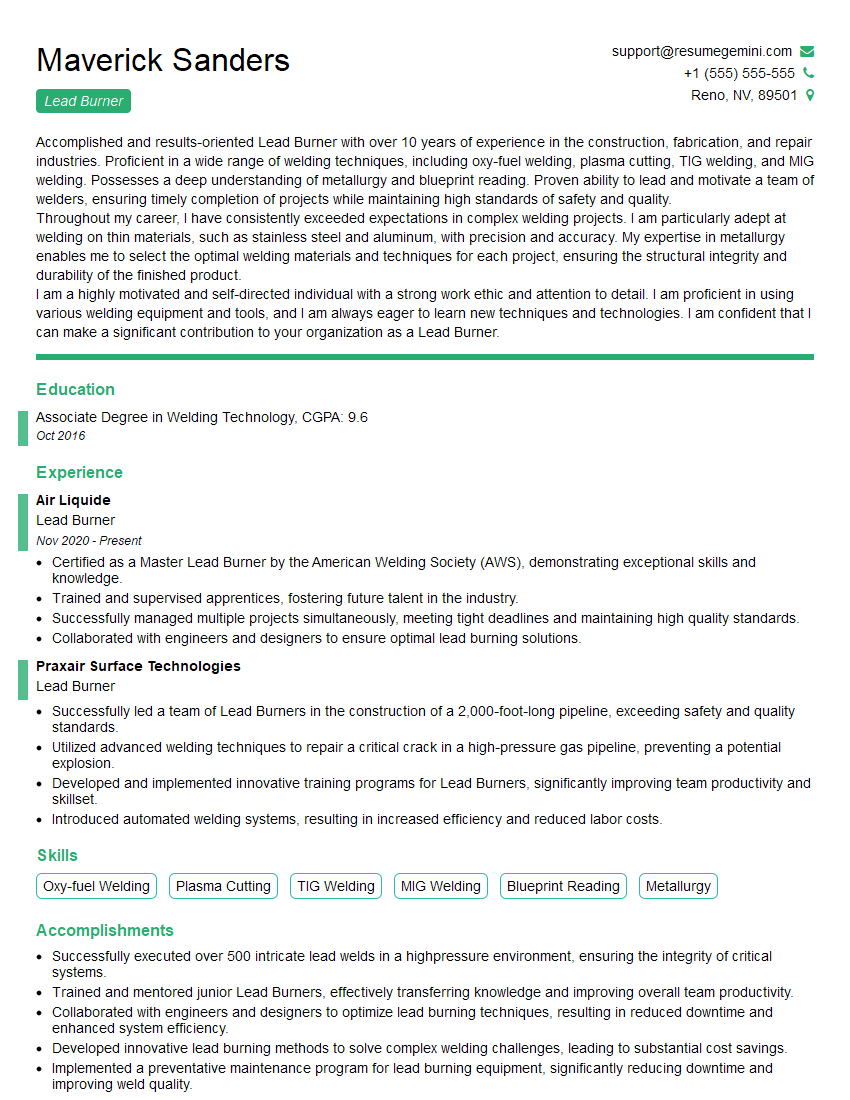

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Burner

1. What types of metals can you lead burn?

A lead burner is responsible for joining together pieces of metal using a lead-based solder. The type of metal that can be lead burned depends on the type of solder that is used.

- Soft solders, which are made of lead and tin, can be used to join together metals such as copper, brass, and steel.

- Hard solders, which are made of lead and antimony, can be used to join together metals such as cast iron and stainless steel.

2. What are the different types of lead burning joints?

There are three main types of lead burning joints:

Butt joint

- A butt joint is formed by placing two pieces of metal end-to-end.

- A lead burner then uses a lead-based solder to join the two pieces together.

Lap joint

- A lap joint is formed by overlapping two pieces of metal.

- A lead burner then uses a lead-based solder to join the two pieces together.

Edge joint

- A edge joint is formed by placing two pieces of metal edge-to-edge.

- A lead burner then uses a lead-based solder to join the two pieces together.

3. What are the different types of lead burning torches?

There are two main types of lead burning torches:

Air-acetylene torch

- An air-acetylene torch uses a mixture of acetylene and air to produce a flame.

- Air-acetylene torches are commonly used for lead burning because they produce a hot, concentrated flame.

Oxy-acetylene torch

- An oxy-acetylene torch uses a mixture of acetylene and oxygen to produce a flame.

- Oxy-acetylene torches produce a hotter flame than air-acetylene torches, but they are also more expensive to operate.

4. What are the safety precautions that must be taken when lead burning?

Lead burning is a hazardous occupation, and several safety precautions must be taken to protect the health of the lead burner.

- Lead burners must wear appropriate personal protective equipment, including a respirator, gloves, and eye protection.

- Lead burners must work in a well-ventilated area to avoid inhaling lead fumes.

- Lead burners must never eat or drink while working.

- Lead burners must wash their hands thoroughly after working.

5. What are the different applications of lead burning?

Lead burning is used in a variety of applications, including:

- Joining together pieces of metal in the construction of tanks, boilers, and other pressure vessels.

- Repairing leaks in metal pipes and fittings.

- Creating lead-lined surfaces in chemical processing equipment.

- Making lead castings.

6. What are the challenges of lead burning?

Lead burning is a challenging occupation that requires a high level of skill and experience.

- Lead burners must be able to work with a variety of metals and solders.

- Lead burners must be able to produce high-quality welds that meet strict standards.

- Lead burners must be able to work in a safe and efficient manner.

7. What is the future of lead burning?

The future of lead burning is uncertain.

- The use of lead in industrial applications is declining due to concerns about its toxicity.

- Lead burning is a hazardous occupation, and there are concerns about the health effects of lead exposure.

- However, lead burning is still essential for certain applications, such as the construction of pressure vessels and the repair of lead-lined surfaces.

It is likely that lead burning will continue to be used in these applications for the foreseeable future.

8. What are the qualifications that are required to become a lead burner?

To become a lead burner, you must typically have:

- A high school diploma or equivalent.

- An apprenticeship in lead burning or a related trade.

- Experience working with metals and solders.

- A strong understanding of welding and soldering techniques.

- Excellent hand-eye coordination.

- The ability to work safely and efficiently in a hazardous environment.

9. What is the career outlook for lead burners?

The career outlook for lead burners is expected to be good over the next few years.

- The demand for lead burners is expected to increase in the construction, manufacturing, and chemical processing industries.

- However, the declining use of lead in industrial applications may limit the growth of the lead burning industry.

Overall, the career outlook for lead burners is expected to be positive, but it is important to be aware of the potential challenges that the industry faces.

10. What is the average salary for a lead burner?

The average salary for a lead burner in the United States is $45,000 per year.

- The salary for a lead burner can vary depending on their experience, skills, and location.

- Lead burners with more experience and skills can earn higher salaries.

- Lead burners who work in high-demand areas can also earn higher salaries.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Burner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Burner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Lead Burner is a highly specialized professional responsible for performing complex welding operations on various types of lead-based materials. This multifaceted role encompasses a comprehensive range of duties, including:

1. Fabrication and Repair

Plays a pivotal role in the manufacturing, fabrication, and repair of lead products, employing specialized tools and techniques.

- Effectively welds lead sheets, pipes, and other components to construct and restore a variety of lead-based structures and equipment.

- Expertly repairs cracks, leaks, and other defects in lead-lined tanks, vessels, and piping systems, ensuring their integrity and functionality.

2. Assembly and Installation

Contributes to the assembly, installation, and maintenance of lead-lined equipment and structures, ensuring adherence to specifications and safety standards.

- Skillfully assembles and installs lead sheeting, flashing, and other components for use in roofing, waterproofing, and radiation protection applications.

- Provides ongoing maintenance and repairs to installed lead-based systems, guaranteeing their reliability and longevity.

3. Quality Control and Inspection

Rigorously inspects and tests completed lead-based fabrications to ensure compliance with established quality standards and safety regulations.

- Thoroughly examines welds for defects, ensuring they meet specified criteria for strength, integrity, and appearance.

- Consistently monitors and records the quality of lead-based materials and products, adhering to industry best practices and regulations.

4. Safety and Compliance

Upholds the highest standards of workplace safety and environmental compliance in all aspects of lead-related operations.

- Meticulously follows established safety protocols for handling, storing, and using lead and related materials, minimizing potential risks.

- Actively participates in safety training programs and maintains up-to-date knowledge of industry regulations and best practices.

Interview Tips

To excel in your Lead Burner interview, thorough preparation is key. Here are some invaluable tips and strategies to help you ace the interview and showcase your exceptional skills and qualifications:

1. Research the Company and Industry

Gain a comprehensive understanding of the company’s background, products or services, and industry standing. This knowledge will enable you to articulate your interest in the role and demonstrate your alignment with the company’s goals.

- Visit the company’s website, social media pages, and industry publications to gather information.

- Research the specific industry sector and identify key trends and challenges.

2. Highlight Your Technical Proficiency

Emphasize your in-depth knowledge of lead welding techniques, equipment, and safety protocols. Provide specific examples of projects where you successfully applied your skills.

- Describe your expertise in various lead welding processes, such as oxy-acetylene welding, TIG welding, and plasma arc welding.

- Showcase your ability to interpret blueprints, specifications, and work orders.

3. Demonstrate Your Safety Consciousness

Reiterate your commitment to workplace safety and environmental compliance. Discuss your knowledge of lead handling and storage regulations, and highlight your experience in implementing safety measures.

- Emphasize your understanding of the potential hazards associated with lead and your adherence to safety protocols.

- Provide examples of how you have successfully implemented safety measures in previous roles.

4. Practice Your Interview Skills

Role-playing interview questions and answers can significantly boost your confidence and polish your presentation. Ask a friend or family member to conduct mock interviews.

- Prepare for common interview questions, such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”

- Practice delivering clear and concise answers that highlight your qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lead Burner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.