Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lead Die Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lead Die Molder so you can tailor your answers to impress potential employers.

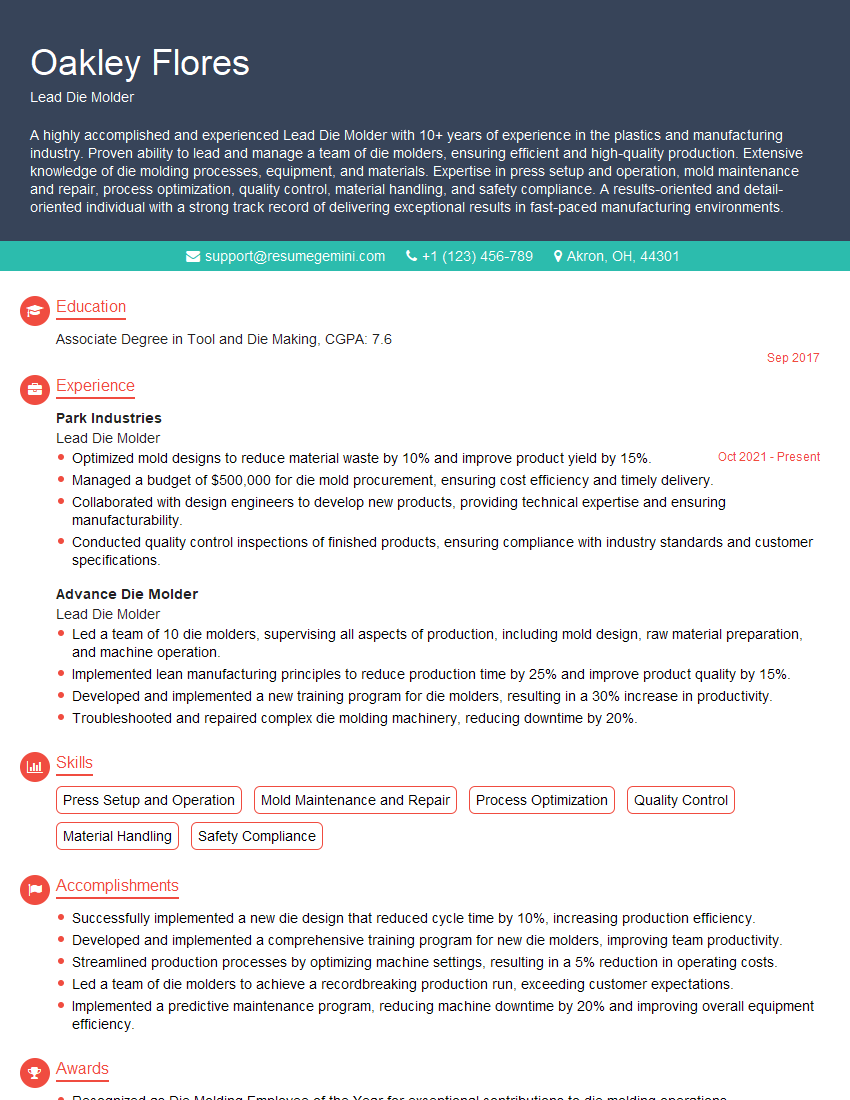

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Die Molder

1. What types of die molding processes are you familiar with?

- Injection molding

- Extrusion molding

- Compression molding

- Blow molding

- Thermoforming

2. What are the key factors to consider when designing a mold?

Material selection

- The type of plastic being molded

- The desired properties of the molded part

- The cost of the material

Mold design

- The geometry of the part

- The number of cavities in the mold

- The type of gating system

- The cooling system

3. What are the common defects that can occur in die molded parts?

- Short shots

- Flash

- Sink marks

- Weld lines

- Voids

4. How do you troubleshoot defects in die molded parts?

- Identify the type of defect

- Determine the cause of the defect

- Implement corrective action

- Verify that the corrective action has resolved the defect

5. What are the safety procedures that must be followed when working with die molding equipment?

- Wear appropriate safety gear

- Be aware of the location of safety equipment

- Follow lockout/tagout procedures

- Never operate equipment unless you are trained and authorized

- Report any unsafe conditions or practices

6. What is your quality control process for die molded parts?

- Inspect parts for defects

- Measure parts to ensure that they meet specifications

- Test parts to ensure that they meet performance requirements

- Document all quality control results

7. What are the latest trends in die molding technology?

- The use of advanced materials

- The development of new molding processes

- The use of automation and robotics

- The use of computer-aided design and manufacturing (CAD/CAM)

8. What are your strengths and weaknesses as a Lead Die Molder?

- Strengths:

- Extensive experience in die molding

- Strong knowledge of mold design and construction

- Ability to troubleshoot and resolve defects

- Excellent communication and interpersonal skills

- Weaknesses:

- Limited experience with some of the latest die molding technologies

- Not familiar with all of the latest quality control techniques

9. What are your salary expectations?

- My salary expectations are commensurate with my experience and qualifications.

- I am open to negotiating a salary that is fair and competitive.

- I am more interested in finding a challenging and rewarding position than in maximizing my salary.

10. Do you have any questions for me?

- What is the company’s culture like?

- What are the company’s growth plans?

- What are the company’s expectations for the Lead Die Molder?

- What is the company’s training and development program?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Die Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Die Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Lead Die Molder is a pivotal role within any manufacturing organization, entrusted with the critical responsibility of ensuring the smooth and efficient operation of die molding processes. This role demands a combination of technical expertise, leadership qualities, and a deep understanding of industry best practices.

1. Process Management

The incumbent will be directly involved in setting up and operating molding equipment, ensuring optimal performance and adherence to quality standards. They will monitor critical process parameters, troubleshoot any issues that arise, and implement corrective actions to maintain production efficiency and product quality.

- Set up and operate die molding equipment, including injection molding machines, compression molding machines, and other specialized equipment.

- Monitor process parameters, such as temperature, pressure, and cycle time, to ensure optimal performance and product quality.

- Identify and troubleshoot process issues, and implement corrective actions to minimize downtime and maintain production efficiency.

2. Team Leadership

The Lead Die Molder is responsible for leading and motivating a team of Die Molders. They will provide guidance, training, and support to team members, while also ensuring that all safety protocols and work instructions are followed diligently.

- Lead and motivate a team of Die Molders, providing guidance, training, and support.

- Ensure that all team members adhere to safety protocols and work instructions.

- Delegate tasks and responsibilities to team members based on their skills and experience.

3. Quality Control

The Lead Die Molder is responsible for ensuring that all molded products meet the required quality standards. They will conduct regular inspections, analyze data, and implement quality improvement initiatives to continuously enhance product quality.

- Inspect molded products for defects and ensure compliance with quality standards.

- Analyze quality data to identify areas for improvement and implement corrective actions.

- Participate in quality improvement initiatives to continuously enhance product quality.

4. Continuous Improvement

The Lead Die Molder is expected to actively participate in continuous improvement initiatives. They will identify areas for improvement, develop and implement solutions, and track the results of their efforts.

- Identify areas for improvement in the die molding process.

- Develop and implement solutions to improve process efficiency and product quality.

- Track the results of implemented solutions and make further improvements as needed.

Interview Tips

Preparing thoroughly for your interview is crucial to making a positive impression on the hiring manager. Here are some tips to help you ace the interview for a Lead Die Molder position:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a better understanding of the company’s culture, goals, and the specific responsibilities of the Lead Die Molder role. You can find this information on the company’s website, LinkedIn page, or through industry publications.

- Visit the company’s website to learn about their history, mission, and products.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies in die molding.

- Connect with current or former employees on LinkedIn to gain insights into the company culture and the Lead Die Molder role.

2. Highlight Your Technical Expertise

During the interview, it is essential to showcase your technical expertise in die molding. Be prepared to discuss your experience with different types of molding equipment, process parameters, and quality control techniques. You should also be able to demonstrate your understanding of the latest industry trends and best practices.

- Quantify your accomplishments using specific examples and metrics.

- Be prepared to discuss your experience with different types of molding equipment and materials.

- Demonstrate your understanding of the latest industry trends and best practices.

3. Emphasize Your Leadership and Communication Skills

As a Lead Die Molder, you will be responsible for leading and motivating a team of employees. During the interview, highlight your leadership skills and ability to communicate effectively with others. Be prepared to discuss your experience in motivating and developing team members, as well as your ability to resolve conflicts and build consensus.

- Share examples of how you have successfully led and motivated teams in the past.

- Describe your communication style and how you build rapport with others.

- Discuss your experience in resolving conflicts and building consensus.

4. Be Prepared to Discuss Your Continuous Improvement Mindset

Continuous improvement is essential in the manufacturing industry. During the interview, be prepared to discuss your commitment to continuous improvement and your track record of implementing successful improvement initiatives.

- Share examples of how you have identified areas for improvement and implemented solutions.

- Discuss your understanding of lean manufacturing principles and how you have applied them in your work.

- Describe your plans for continuous improvement in the Lead Die Molder role.

Next Step:

Now that you’re armed with the knowledge of Lead Die Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lead Die Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini