Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lead Ingot Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

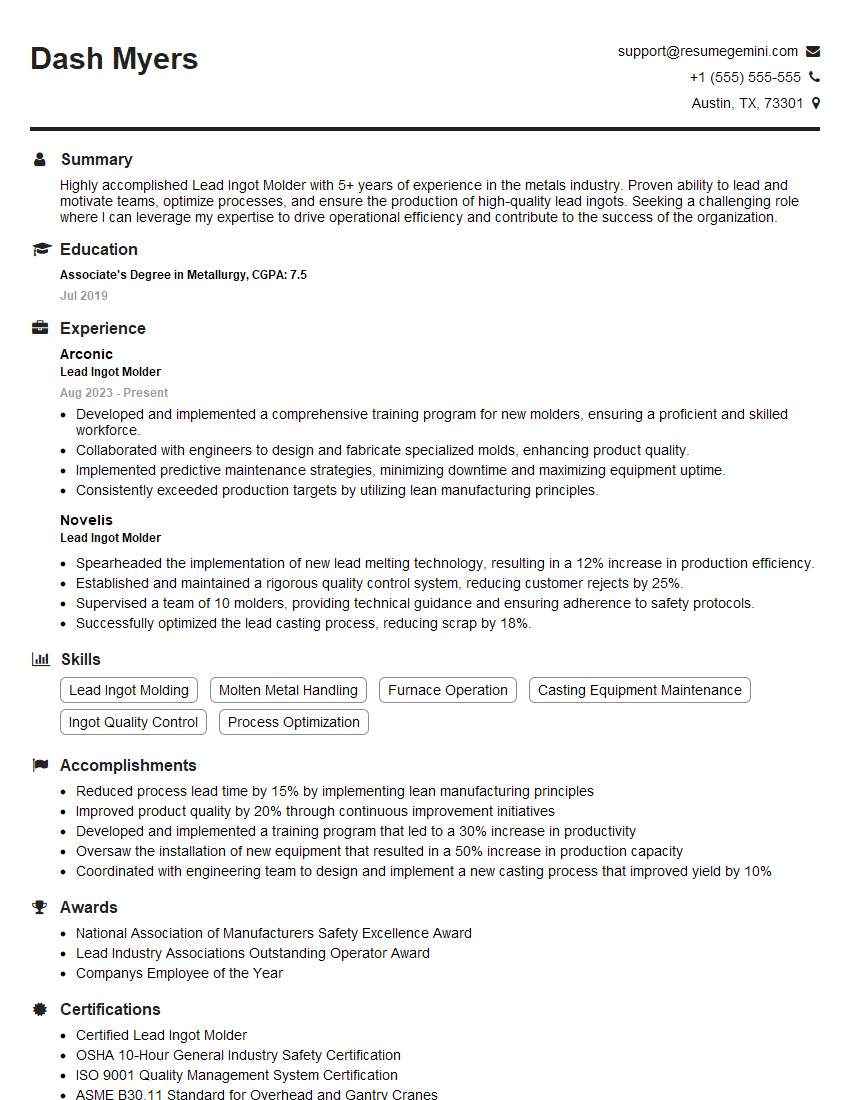

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Ingot Molder

1. What are the various types of lead ingots that you have experience in producing?

- Describe the different types of lead ingots, such as primary, secondary, and refined lead ingots.

- Explain the specific characteristics and applications of each type of ingot.

2. Explain the process of lead ingot molding, from raw material preparation to finished product.

subheading of the answer

- Describe the steps involved in preparing the raw lead material, including melting, refining, and fluxing.

- Explain the molding process, including the use of molds, casting techniques, and cooling methods.

subheading of the answer

- Discuss the quality control measures implemented throughout the process to ensure the production of high-quality ingots.

- Explain the importance of maintaining proper temperature control and avoiding contamination during the molding process.

3. What are the key factors that influence the quality of lead ingots?

- Discuss the role of raw material purity, including the presence of impurities and alloying elements.

- Explain the impact of molding conditions, such as temperature, cooling rate, and mold design.

- Describe the importance of proper handling and storage practices to maintain the quality of finished ingots.

4. What are the common defects that can occur in lead ingots and how can they be prevented?

- Identify common defects such as porosity, cracks, surface defects, and inclusions.

- Explain the causes and mechanisms of these defects.

- Describe preventive measures that can be implemented during the molding process to minimize the occurrence of defects.

5. How do you ensure that the lead ingots meet the required specifications and customer requirements?

- Describe the testing and inspection procedures used to verify the quality of the ingots.

- Explain the importance of maintaining traceability throughout the production process.

- Discuss the steps taken to address any non-conformities or customer complaints.

6. What are the safety hazards associated with lead ingot molding and how do you mitigate them?

- Identify potential hazards such as lead exposure, burns, and equipment-related injuries.

- Explain the safety protocols and personal protective equipment (PPE) required for safe operation.

- Describe the engineering controls and ventilation systems implemented to minimize exposure to lead and other hazardous substances.

7. How do you stay updated with the latest industry trends and best practices in lead ingot molding?

- Describe your involvement in industry organizations or conferences.

- Explain how you keep abreast of new technologies and innovations.

- Discuss the importance of continuous learning and professional development for maintaining expertise in the field.

8. What is your experience with optimizing the lead ingot molding process for efficiency and cost-effectiveness?

- Describe your efforts to improve productivity, reduce waste, and minimize operating costs.

- Explain the use of lean manufacturing principles or other efficiency improvement techniques.

- Discuss the importance of ongoing process evaluation and continuous improvement.

9. How do you handle equipment malfunctions or unexpected interruptions during the lead ingot molding process?

- Describe your troubleshooting and problem-solving skills.

- Explain the protocols for reporting and resolving equipment issues.

- Discuss the importance of effective communication and coordination with other team members during emergencies.

10. Describe your experience with managing a team of lead ingot molders and ensuring their productivity and safety.

- Explain your leadership style and approach to motivating and supporting your team.

- Describe the training and development programs you have implemented.

- Discuss your strategies for maintaining a positive and productive work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Ingot Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Ingot Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Lead Ingot Molder plays a pivotal role in the manufacturing process, ensuring the highest standards of ingot production. Key responsibilities include:

1. Ingot Production and Quality Control

Meticulously monitor and control the ingot molding process, ensuring adherence to specifications and seamless production.

- Calibrate and operate ingot molding machines with precision and expertise.

- Rigorously inspect and test ingots to guarantee dimensional accuracy, structural integrity, and adherence to customer requirements.

2. Process Optimization and Troubleshooting

Identify and resolve production challenges swiftly and efficiently, minimizing downtime and enhancing productivity.

- Analyze production data and implement process improvements to maximize efficiency and reduce waste.

- Troubleshoot and resolve mechanical or operational issues promptly, ensuring smooth and uninterrupted operations.

3. Equipment Maintenance and Calibration

Maintain and calibrate production equipment to ensure optimal performance and longevity.

- Conduct routine maintenance, lubrication, and cleaning of ingot molding machines.

- Calibrate equipment regularly to achieve precise ingot dimensions and minimize defects.

4. Safety and Environmental Compliance

Prioritize workplace safety and adhere to environmental regulations to create a positive and sustainable work environment.

- Enforce safety protocols and ensure proper use of personal protective equipment.

- Monitor environmental impact and comply with waste management and emission regulations.

Interview Tips

To ace your interview for the Lead Ingot Molder position, consider these preparation tips:

1. Research the Company and Role

Thoroughly research the organization and the specific responsibilities of a Lead Ingot Molder. Understand their industry, products, and company culture.

- Visit the company website, LinkedIn profile, and any recent news articles.

- Review the job description carefully and identify the key skills and experience required.

2. Highlight Relevant Experience and Skills

Emphasize your experience and skills that are directly relevant to the role, such as:

- Ingot molding machine operation and maintenance

- Quality control and testing procedures

- Troubleshooting and problem-solving abilities

3. Prepare Examples of Success

Use the STAR method (Situation, Task, Action, Result) to prepare examples of your achievements that demonstrate your capabilities.

- Describe a situation where you implemented process improvements that led to increased efficiency.

- Share an example of how you effectively resolved a production problem, minimizing downtime.

4. Practice Active Listening and Communication

Demonstrate active listening skills by asking clarifying questions and summarizing the interviewer’s statements.

- Speak clearly and concisely, using relevant examples to support your points.

- Be confident in your abilities, but also be open to feedback and suggestions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lead Ingot Molder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.