Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lead Man Over All Dies in Pattern Shop interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lead Man Over All Dies in Pattern Shop so you can tailor your answers to impress potential employers.

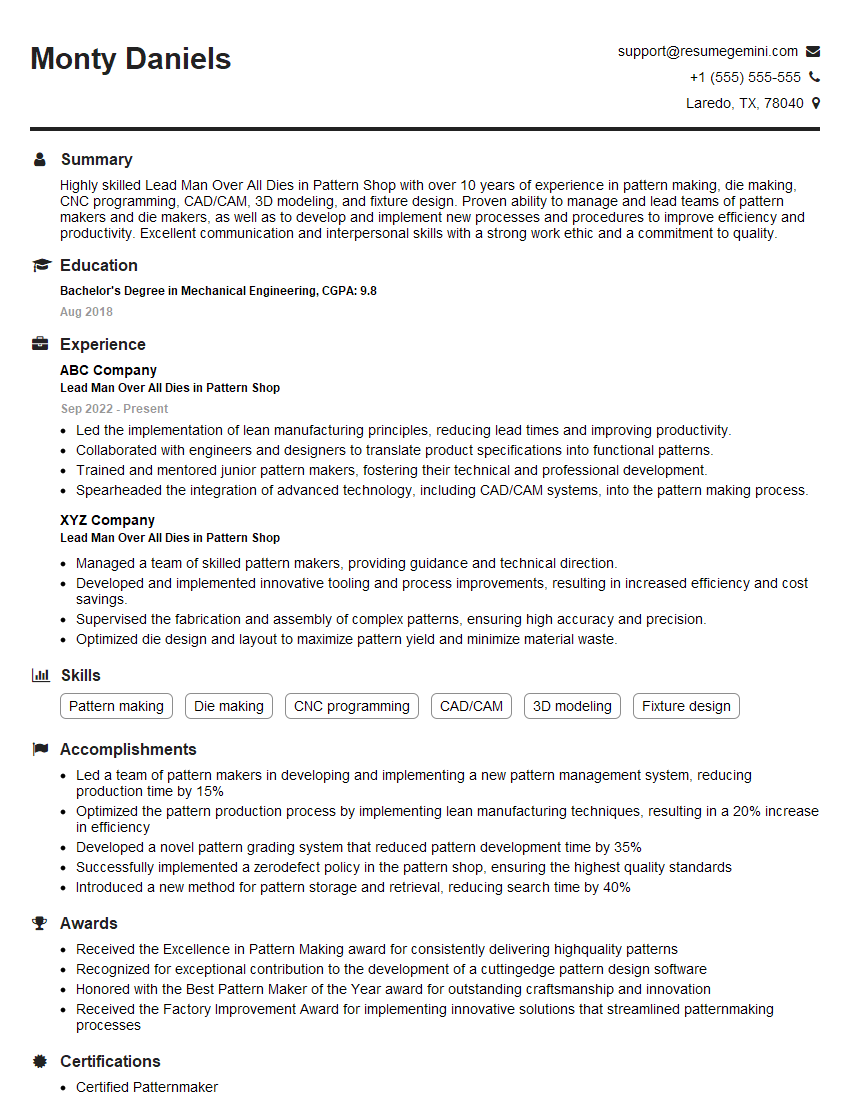

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Man Over All Dies in Pattern Shop

1. What are the different types of dies used in a pattern shop, and what are the specific functions of each type?

- Flat dies are used for cutting flat shapes out of sheet metal.

- Forming dies are used to bend and shape sheet metal into complex shapes.

- Progressive dies are used to produce multiple operations in a single press stroke, such as punching, forming, and cutting.

- Transfer dies are used to transfer a blank from one station to another in a press, allowing for multiple operations to be performed on the same blank in different stations.

2. What are the different types of materials used to make dies, and what are the advantages and disadvantages of each type?

Cold-rolled steel

- Advantages: low cost, easy to machine, good strength-to-weight ratio

- Disadvantages: prone to rust, can be brittle, not suitable for high-volume applications

Hot-rolled steel

- Advantages: more durable than cold-rolled steel, better wear resistance

- Disadvantages: more expensive, more difficult to machine

Tool steel

- Advantages: very durable, long-lasting, can be used for high-volume applications

- Disadvantages: expensive, difficult to machine

3. What are the key factors to consider when designing a die, and how do these factors affect the die’s performance and cost?

- The material of the die

- The type of die

- The size and complexity of the die

- The volume of production

4. What are the different types of die sets, and how do they affect the die’s performance?

- Solid die sets are made from a single piece of metal and offer the highest level of precision and durability.

- Sectional die sets are made from multiple pieces of metal that are assembled together, offering greater flexibility and lower cost than solid die sets.

- Modular die sets are made from standard components that can be assembled in different configurations, offering the highest level of flexibility and customization.

5. What are the different types of die coatings, and how do they affect the die’s performance?

- Chromium nitride coatings are hard and wear-resistant, reducing die wear and extending die life.

- Titanium nitride coatings are even harder than chromium nitride coatings, offering even greater wear resistance.

- Diamond-like carbon coatings are the hardest of all die coatings, offering the highest level of wear resistance and durability.

6. What are the most common problems that can occur with dies, and how can these problems be prevented or solved?

- Die wear can be prevented by using the correct materials and coatings, and by proper sharpening and maintenance of the die.

- Die breakage can be prevented by using the correct materials and design, and by avoiding excessive loads and impact forces.

- Die galling can be prevented by using proper lubrication and by avoiding excessive sliding contact between the die and the workpiece.

7. What are the most important quality control checks that should be performed on dies?

- Die dimensions and tolerances should be checked using a coordinate measuring machine or other precision measuring equipment.

- Die surfaces should be checked for scratches, nicks, and other defects that could affect the die’s performance.

- Die coatings should be checked for thickness and adhesion to ensure that they are providing the desired level of protection.

8. What are the latest trends in die manufacturing, and how are these trends improving the performance and cost of dies?

- The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) is improving the accuracy and efficiency of die manufacturing.

- The use of new materials and coatings is improving the performance and durability of dies.

- The use of new technologies, such as additive manufacturing (3D printing), is reducing the cost and lead time for die manufacturing.

9. What are the key skills and knowledge required for a successful career as a Lead Man Over All Dies in Pattern Shop?

- Thorough understanding of die design, manufacturing, and maintenance

- Strong leadership and communication skills

- Ability to work independently and as part of a team

- Ability to meet tight deadlines and budgets

10. How do you stay up-to-date on the latest trends in die manufacturing?

- Read industry publications and attend trade shows

- Participate in online forums and discussion groups

- Attend continuing education courses and seminars

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Man Over All Dies in Pattern Shop.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Man Over All Dies in Pattern Shop‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Lead Man Over All Dies in Pattern Shop is a highly responsible position that oversees the entire die-making process. The key responsibilities of this role include:

1. Die Design and Development

Collaborate with design engineers to create and develop new dies

- Analyze product specifications and drawings

- Determine appropriate materials and manufacturing processes

- Design and fabricate dies using CAD/CAM software

- Conduct testing and evaluation to ensure die performance

2. Die Maintenance and Repair

Maintain and repair dies to ensure optimal performance

- Inspect dies for wear and damage

- Troubleshoot and resolve production issues

- Perform preventive maintenance to minimize downtime

- Coordinate with vendors for necessary repairs or replacements

3. Production Supervision

Supervise a team of die makers and oversee production operations

- Assign tasks and monitor progress

- Ensure compliance with safety and quality standards

- Resolve production issues and implement improvements

- Train and develop team members

4. Quality Control

Ensure the quality of all dies produced and maintained

- Establish and implement quality control procedures

- Perform inspections and tests to verify die accuracy

- Document and record quality data

- Collaborate with engineers to identify and resolve quality issues

Interview Tips

To prepare for an interview for a Lead Man Over All Dies in Pattern Shop position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and products. Research the specific role and its responsibilities to demonstrate your understanding of the job requirements.

- Visit the company website and read its mission statement and recent news.

- Review the job description thoroughly and identify the key skills and experience required.

2. Highlight Your Technical Skills

Emphasize your expertise in die design, fabrication, and maintenance. Showcase your proficiency in CAD/CAM software and your understanding of manufacturing processes.

- Provide examples of complex dies you have designed and developed.

- Explain your experience in troubleshooting and resolving production issues.

3. Demonstrate Your Leadership Abilities

Highlight your ability to lead and supervise a team of die makers. Describe your experience in motivating and mentoring others, as well as your approach to conflict resolution.

- Share examples of how you have successfully managed and developed a team.

- Explain your strategies for ensuring productivity and maintaining a positive work environment.

4. Prepare for Technical Questions

Expect to be asked technical questions about die design, fabrication, and maintenance. Be prepared to discuss your knowledge of different materials, manufacturing processes, and quality control procedures.

- Review your technical notes and practice answering common interview questions.

- Consider preparing a portfolio or presentation that showcases your technical skills.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lead Man Over All Dies in Pattern Shop role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.