Are you gearing up for an interview for a Lead Nitrate Processor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lead Nitrate Processor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

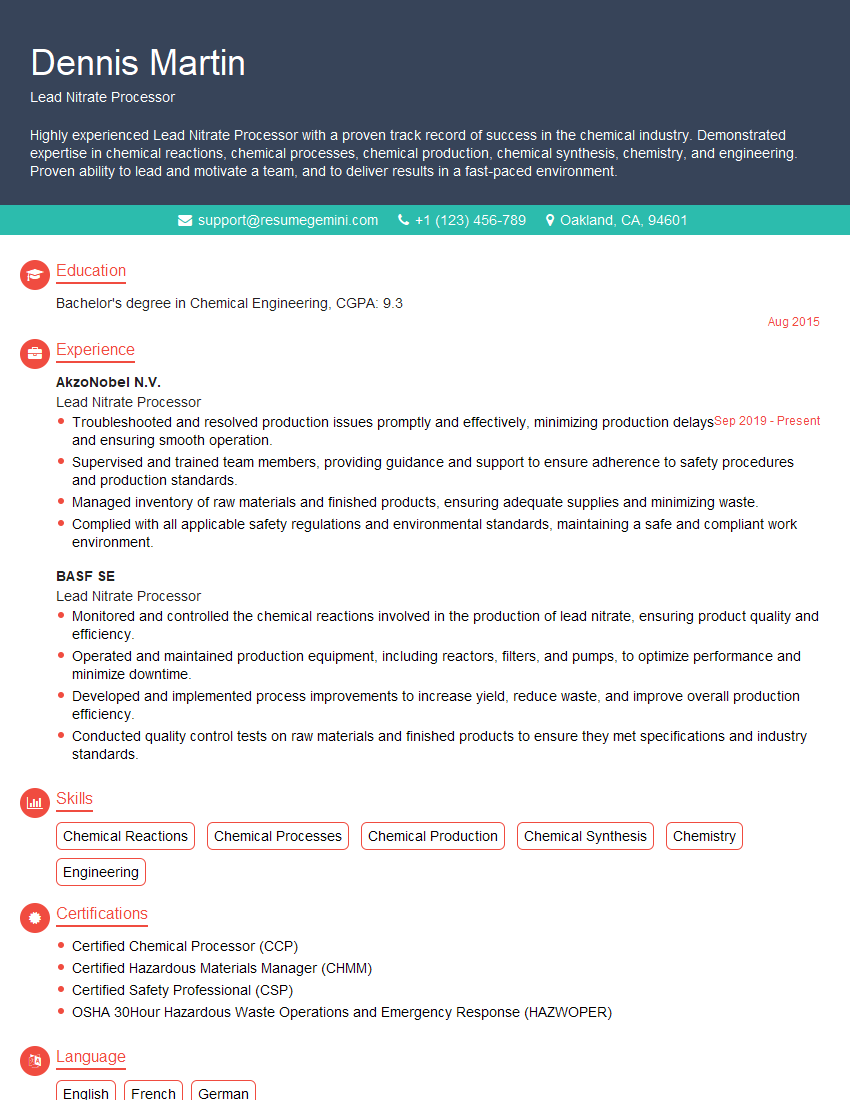

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Nitrate Processor

1. Explain the chemical process involved in the production of lead nitrate?

Assistant’s Answer:

- The process begins with the reaction of lead oxide (PbO) with nitric acid (HNO3) to form lead nitrate [Pb(NO3)2] and water (H2O).

- The resulting solution is then concentrated by evaporation to remove excess water and crystallize the lead nitrate.

- The crystals are then separated from the mother liquor by filtration and dried to obtain pure lead nitrate.

2. What are the key parameters that need to be controlled during the crystallization process to ensure the production of high-quality lead nitrate crystals?

Assistant’s Answer:

Temperature Control:

- Maintaining a constant temperature during crystallization is crucial to control the crystal size and purity.

Concentration Control:

- The concentration of the lead nitrate solution must be carefully controlled to promote the formation of well-defined crystals.

Impurity Removal:

- Impurities can hinder the growth of lead nitrate crystals. Regular monitoring and removal of impurities are essential.

3. How do you optimize the yield of lead nitrate in the crystallization process?

Assistant’s Answer:

- Optimizing the crystallization parameters, such as temperature, concentration, and agitation, can increase the yield.

- Seeding the solution with small lead nitrate crystals can initiate crystal growth and improve yield.

- Slow cooling of the solution allows for the formation of larger crystals with better quality.

4. What are the common impurities found in lead nitrate and how do you minimize their presence?

Assistant’s Answer:

- Lead oxides: Controlled temperature and pH levels during the reaction can minimize lead oxide impurities.

- Nitric acid: Thorough washing of the crystals after crystallization removes residual nitric acid.

- Heavy metals: Using high-purity starting materials and employing precipitation or ion exchange techniques can reduce heavy metal impurities.

5. How do you ensure the quality of the final lead nitrate product?

Assistant’s Answer:

- Regular chemical analysis to determine purity and compliance with specifications.

- Physical inspections to check for crystal size, shape, and color.

- Adherence to quality control protocols throughout the production process.

6. What safety precautions should be taken when working with lead nitrate?

Assistant’s Answer:

- Wear appropriate personal protective equipment (PPE), such as gloves, masks, and goggles.

- Handle lead nitrate in well-ventilated areas to avoid inhalation of dust.

- Dispose of lead nitrate waste properly according to environmental regulations.

7. What are the applications of lead nitrate in various industries?

Assistant’s Answer:

- Fertilizer: As a source of nitrogen in fertilizers.

- Pigments: Lead nitrate is used in the production of yellow pigments.

- Explosives: Lead nitrate is an oxidizing agent in certain types of explosives.

- Medicine: It is used in the production of some pharmaceutical products.

8. How do you stay updated on the latest advancements and best practices in lead nitrate processing?

Assistant’s Answer:

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Network with other professionals in the field.

9. Describe a challenging situation you faced in your previous role as a Lead Nitrate Processor and how you overcame it.

Assistant’s Answer:

- Challenge: Optimizing the crystallization process to increase yield and crystal quality.

- Actions: Conducted experiments to test different parameters, consulted with experts, and implemented process improvements.

- Results: Increased yield by 15% and improved crystal quality, leading to reduced rejections and increased customer satisfaction.

10. How would you handle a situation where you discover a potential deviation from the production specifications?

Assistant’s Answer:

- Investigate: Identify the root cause and extent of the deviation.

- Implement Corrective Actions: Take steps to correct the deviation and prevent recurrence.

- Communicate: Inform stakeholders and quality control department about the deviation and corrective actions.

- Monitor: Track the situation to ensure the issue is resolved and production is back on track.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Nitrate Processor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Nitrate Processor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lead Nitrate Processors are responsible for the production of lead nitrate, a chemical compound used in a variety of industrial and commercial applications. Their key responsibilities include:

1. Operating and maintaining lead nitrate processing equipment

Lead Nitrate Processors must be able to operate and maintain a variety of equipment used in the lead nitrate production process, including reactors, filters, and pumps.

- Monitor and adjust equipment settings to ensure optimal performance.

- Troubleshoot and repair equipment malfunctions.

2. Monitoring and controlling the lead nitrate production process

Lead Nitrate Processors must be able to monitor and control the lead nitrate production process to ensure that the product meets specifications.

- Monitor process variables such as temperature, pressure, and flow rate.

- Make adjustments to the process as needed to maintain product quality.

3. Ensuring the safety of the lead nitrate production process

Lead Nitrate Processors must be able to ensure the safety of the lead nitrate production process.

- Follow all safety procedures.

- Wear appropriate personal protective equipment.

4. Maintaining a clean and organized work area

Lead Nitrate Processors must be able to maintain a clean and organized work area.

- Clean and disinfect equipment regularly.

- Keep work area free of clutter and debris.

Interview Tips

To ace an interview for a Lead Nitrate Processor position, it is important to be prepared. Here are some tips:

1. Research the company and the role

Before the interview, take some time to research the company and the role you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website.

- Read industry publications.

- Talk to people who work at the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice your answers to these questions in advance.

- “Tell me about yourself.”

- “Why are you interested in this role?”

- “What are your strengths and weaknesses?”

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in the lead nitrate production industry. Be prepared to talk about your skills and knowledge.

- Highlight your experience in operating and maintaining lead nitrate processing equipment.

- Describe your experience in monitoring and controlling the lead nitrate production process.

- Explain how you have ensured the safety of the lead nitrate production process.

4. Be enthusiastic and professional

The interviewer will be looking for someone who is enthusiastic about the role and who is professional in their demeanor. Be yourself and be confident in your abilities.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Dress appropriately for the interview.

Next Step:

Now that you’re armed with the knowledge of Lead Nitrate Processor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lead Nitrate Processor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini