Feeling lost in a sea of interview questions? Landed that dream interview for Lead Pressman but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lead Pressman interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

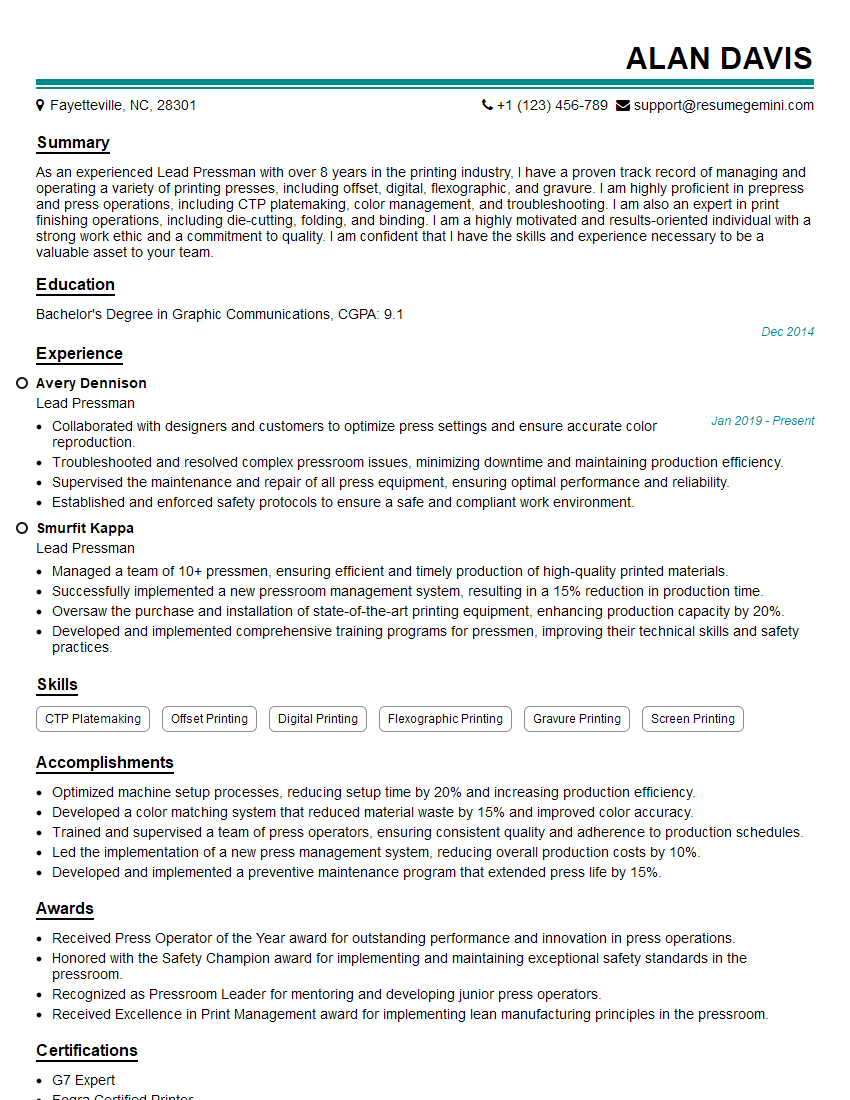

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Pressman

1. What are the key responsibilities of a Lead Pressman?

As a Lead Pressman, my responsibilities encompass:

- Supervising and guiding pressroom operations to ensure efficient and quality production

- Setting up and maintaining printing presses, including adjustments, troubleshooting, and preventive maintenance

- Managing press schedules, coordinating with other departments, and ensuring timely delivery of print jobs

- Training and mentoring junior pressmen, fostering a highly skilled and motivated team

- Monitoring press performance, identifying areas for improvement, and implementing process optimizations

2. Describe your experience in conducting pressroom audits

Pre-Audit Preparation

- Gather data on press performance, production efficiency, and quality control metrics

- Review maintenance records and identify any potential areas of concern

- Prepare a detailed audit plan based on the identified areas

Audit Execution

- Thoroughly inspect presses, checking for wear and tear, alignment, and proper maintenance

- Review press settings and compare them to industry best practices

- Observe press operators’ techniques and identify areas for improvement

- Evaluate the efficiency of production processes, including setup times and ink consumption

Post-Audit Analysis

- Analyze the collected data and identify areas for improvement

- Develop a comprehensive report detailing findings and recommendations

- Present the report to management and discuss potential solutions

3. How do you stay up-to-date with the latest printing technologies?

- Attend industry conferences and trade shows to learn about new equipment and techniques

- Read trade publications and research articles to stay informed on industry advancements

- Participate in online forums and discussions to exchange knowledge with other professionals

- Collaborate with equipment manufacturers and suppliers to gain insights into upcoming technologies

- Attend training programs and workshops to enhance my technical skills and knowledge

4. Can you explain the process of color matching and the techniques you use to achieve accurate colors?

- Analyzing the desired color using color measurement tools, such as spectrophotometers

- Creating a press profile based on the press characteristics and paper type

- Using color management software to adjust ink densities and ensure color accuracy

- Employing calibration techniques, such as gray balance and color bars, to fine-tune the press

- Regularly monitoring color output and making necessary adjustments to maintain consistency

5. Describe the steps involved in troubleshooting a printing press issue and your problem-solving strategy

- Identifying the symptoms and isolating the problem area

- Consulting technical manuals and diagrams to understand the system

- Performing diagnostic tests and inspections to locate the root cause

- Developing and implementing a repair or adjustment plan

- Testing the solution and verifying that the issue has been resolved

6. How do you ensure the safety of your team while operating the printing presses?

- Enforcing strict adherence to safety protocols and guidelines

- Providing comprehensive safety training to all press operators

- Conducting regular safety inspections and audits to identify potential hazards

- Maintaining a clean and well-organized work environment

- Promoting a culture of safety awareness and reporting any incidents promptly

7. What techniques do you use to optimize press efficiency and minimize waste?

- Utilizing lean manufacturing principles to streamline processes and reduce setup times

- Implementing automated press controls to improve accuracy and consistency

- Monitoring production data to identify areas for improvement and reduce waste

- Using high-quality materials and equipment to minimize breakdowns and defects

- Training press operators on waste-reducing practices and techniques

8. How do you manage production schedules and ensure timely delivery of print jobs?

- Collaborating with the sales team to understand customer requirements and deadlines

- Creating a detailed production schedule that takes into account press availability and capacity

- Monitoring progress and communicating with customers about the status of their orders

- Prioritizing jobs based on urgency and customer commitments

- Identifying potential bottlenecks and implementing contingency plans to minimize delays

9. Describe your experience in working with different types of printing materials and how you adjust your techniques accordingly

I have extensive experience working with a wide range of printing materials, including:

- Paper of various weights, finishes, and textures

- Cardboard and specialty stocks for packaging and promotional materials

- Vinyl and other synthetic materials for signage and banners

To adjust my techniques accordingly, I consider factors such as:

- The porosity and absorbency of the material

- The desired print quality and color accuracy

- The drying time and curing requirements

By carefully adjusting printing parameters, such as ink viscosity, pressure, and temperature, I can achieve optimal print results on any type of material.

10. How do you approach continuous improvement and identify opportunities for innovation in the pressroom?

- Regularly reviewing press performance metrics and identifying areas for improvement

- Seeking feedback from press operators and other team members to gain insights into potential challenges

- Attending workshops and conferences to learn about new technologies and best practices

- Collaborating with industry experts and suppliers to explore innovative solutions

- Implementing pilot projects to test new ideas and evaluate their effectiveness before scaling them up

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Pressman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Pressman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lead Pressmen, also referred to as Printing Press Operators or Pressroom Supervisors, play a crucial role in the printing industry. They are responsible for operating and maintaining printing presses to produce high-quality printed materials.

1. Press Operation and Maintenance

Lead Pressmen are highly skilled in operating various types of printing presses, including offset, digital, and flexographic presses. They are responsible for:

- Setting up and calibrating presses

- Loading and unloading paper and other materials

- Adjusting press settings to ensure optimal print quality

- Monitoring press performance and making necessary adjustments

- Performing routine maintenance and repairs

2. Quality Control

Lead Pressmen are responsible for ensuring that the printed materials meet the highest quality standards. They inspect printed materials for defects, such as color variations, smudges, or misalignments. They also work closely with customers to ensure that their specific requirements are met.

3. Production Planning and Scheduling

Lead Pressmen play a key role in production planning and scheduling. They work with other departments to determine production timelines and ensure that deadlines are met. They also coordinate with customers to schedule deliveries and ensure that orders are fulfilled on time.

4. Team Leadership and Supervision

Lead Pressmen often supervise a team of press operators and other printing personnel. They are responsible for providing training and guidance to their team, ensuring that they are properly trained and follow established procedures. They also monitor the performance of their team and provide feedback to help them improve.

5. Safety and Compliance

Lead Pressmen are responsible for maintaining a safe and compliant work environment. They ensure that all safety regulations are followed and that proper safety equipment is used. They also stay up-to-date on industry standards and best practices.

Interview Tips

Preparing for a Lead Pressman interview can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company you are applying to and the specific position you are interviewing for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities of the Lead Pressman role. Knowing more about the position and the company will help you tailor your answers and demonstrate your interest in both.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” Take some time to practice your answers to these questions so that you can deliver them confidently and clearly. You can also prepare specific examples from your previous experience that demonstrate your skills and abilities.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Lead Pressman position. This includes your technical skills, such as your ability to operate printing presses, as well as your leadership and supervisory skills. Quantify your accomplishments whenever possible to provide tangible evidence of your success.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions to ask the interviewer about the company, the role, or the industry. This will demonstrate your enthusiasm for the opportunity and help you gain a better understanding of the company’s culture and goals.

5. Follow Up

After the interview, send a thank-you note to the interviewer. This is a simple but effective way to show your appreciation for their time and to reiterate your interest in the position. You can also use this opportunity to address any questions or concerns that you may have. A follow-up email can help you stay on top of the interviewer’s mind and remind them of the strengths you bring to the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lead Pressman role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.