Feeling lost in a sea of interview questions? Landed that dream interview for Lead Pressman-Roto Gravure Printing but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lead Pressman-Roto Gravure Printing interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

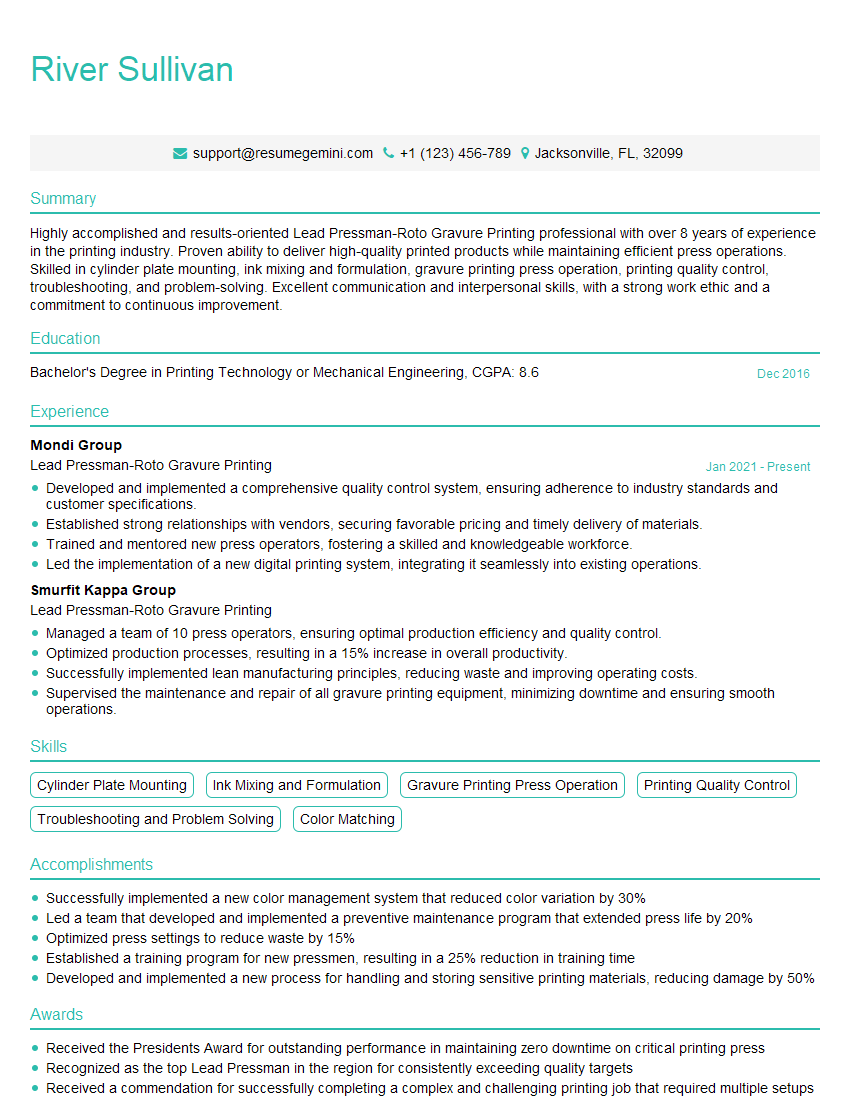

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Pressman-Roto Gravure Printing

1. Explain the process of gravure printing, highlighting the key steps involved?

Gravure printing is a printing process in which the image to be printed is engraved into a metal cylinder. The cylinder is then inked and pressed against paper, transferring the ink to the paper.

- Prepress: The first step in the gravure printing process is prepress. This involves creating a digital file of the image to be printed. The file is then used to create a photoengraved cylinder.

- Press: The photoengraved cylinder is then mounted on a printing press. The press feeds paper into the press, and the cylinder rolls over the paper, transferring the ink to the paper.

- Postpress: After the paper has been printed, it is sent through a series of postpress processes. These processes include drying, cutting, and binding.

2. Describe the different types of gravure printing presses and their capabilities?

Rotary presses

- Rotary presses are the most common type of gravure printing press. They are high-speed presses that can print large volumes of paper.

- Rotary presses are capable of printing on a variety of substrates, including paper, plastic, and metal.

Flatbed presses

- Flatbed presses are slower than rotary presses, but they can print on a wider variety of substrates.

- Flatbed presses are often used for printing high-quality images.

3. What are the key factors that affect the quality of gravure printing?

- Cylinder quality: The quality of the photoengraved cylinder is a major factor in the quality of the printed image.

- Ink quality: The quality of the ink used in gravure printing can also affect the quality of the printed image.

- Paper quality: The quality of the paper used in gravure printing can also affect the quality of the printed image.

- Press settings: The settings of the printing press can also affect the quality of the printed image.

4. What are the common problems that can occur in gravure printing and how can they be resolved?

- Ghosting: Ghosting occurs when an image appears twice on the printed sheet. This can be caused by a variety of factors, including improper cylinder preparation, ink problems, or press problems.

- Mottling: Mottling occurs when the printed image is uneven in color. This can be caused by a variety of factors, including ink problems, paper problems, or press problems.

- Slurring: Slurring occurs when the printed image is blurred. This can be caused by a variety of factors, including cylinder problems, ink problems, or press problems.

5. What are the advantages and disadvantages of gravure printing?

Advantages

- Gravure printing produces high-quality images.

- Gravure printing is a high-speed printing process.

- Gravure printing can be used to print on a variety of substrates.

Disadvantages

- Gravure printing is a complex and expensive printing process.

- Gravure printing requires a long setup time.

- Gravure printing is not well-suited for short-run printing.

6. What are the latest trends in gravure printing?

- Digital gravure: Digital gravure is a new technology that uses digital files to create photoengraved cylinders. This technology is still in its early stages, but it has the potential to revolutionize the gravure printing industry.

- Water-based inks: Water-based inks are becoming increasingly popular in gravure printing. These inks are more environmentally friendly than traditional solvent-based inks.

- Sustainable substrates: Sustainable substrates are becoming increasingly popular in gravure printing. These substrates are made from recycled materials or from renewable resources.

7. How do you ensure that the gravure printing process is efficient and cost-effective?

- Proper planning: Proper planning is essential for ensuring that the gravure printing process is efficient and cost-effective.

- Preventive maintenance: Preventive maintenance is also important for ensuring that the gravure printing process is efficient and cost-effective.

- Waste reduction: Waste reduction is another important factor in ensuring that the gravure printing process is efficient and cost-effective.

8. What are the safety precautions that must be taken when working in a gravure printing environment?

- Wear appropriate safety gear: When working in a gravure printing environment, it is important to wear appropriate safety gear, such as gloves, eye protection, and a respirator.

- Be aware of the hazards: It is also important to be aware of the hazards associated with gravure printing, such as the risk of fire, explosion, and chemical exposure.

- Follow safety procedures: It is important to follow all safety procedures when working in a gravure printing environment.

9. What is your experience with troubleshooting gravure printing problems?

I have several years of experience troubleshooting gravure printing problems. I have successfully resolved a variety of problems, including ghosting, mottling, and slurring.

- Example 1: I once encountered a problem with ghosting on a gravure printing press. I was able to resolve the problem by cleaning the cylinder and adjusting the ink flow.

- Example 2: I also encountered a problem with mottling on a gravure printing press. I was able to resolve the problem by changing the paper stock.

10. What are your career goals?

My career goal is to become a lead pressman in a gravure printing company. I am confident that I have the skills and experience necessary to be successful in this role.

- I am a highly motivated and results-oriented individual.

- I am a team player and I am always willing to go the extra mile.

- I am confident that I can make a significant contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Pressman-Roto Gravure Printing.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Pressman-Roto Gravure Printing‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Lead Pressman-Roto Gravure Printing is responsible for overseeing the operation of rotogravure printing presses and ensuring the production of high-quality printed materials. Key responsibilities include:

1. Press Operation and Maintenance

Operate and maintain rotogravure printing presses, including setting up, adjusting, and troubleshooting machines.

- Adjust press settings to ensure optimal print quality, including ink flow, tension, and temperature

- Identify and resolve printing issues, such as color variations, registration errors, and defects

2. Production Planning and Management

Plan and schedule printing jobs, including preparing press specifications and estimating production times.

- Coordinate with prepress and finishing departments to ensure smooth production flow

- Monitor production progress and make adjustments as needed to meet deadlines

3. Quality Control and Inspection

Inspect printed materials for quality, including color accuracy, registration, and other specifications.

- Use quality control instruments and techniques to evaluate print quality

- Identify and correct defects before materials are released for distribution

4. Team Supervision and Training

Supervise a team of press operators and assist with their training and development.

- Provide guidance and support to team members

- Train new operators on press operation and maintenance procedures

Interview Tips

To ace the interview for a Lead Pressman-Roto Gravure Printing position, candidates should prepare thoroughly and present themselves professionally. Here are some tips:

1. Research the Company and Position

Research the company’s history, products, and industry standing. Familiarize yourself with the specific requirements of the Lead Pressman-Roto Gravure Printing position and tailor your answers accordingly.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in rotogravure printing, including press operation, maintenance, and quality control. Quantify your accomplishments and provide specific examples of your work.

3. Showcase Leadership and Teamwork Abilities

Discuss your experience leading and supervising teams. Provide examples of how you have motivated and developed team members to achieve high performance.

4. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions about the company’s growth plans, printing technology, and opportunities for professional development.

5. Practice Your Answers

Rehearse your answers to common interview questions. This will help you speak confidently and articulate your skills and experience effectively.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lead Pressman-Roto Gravure Printing, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lead Pressman-Roto Gravure Printing positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.