Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lead Quality Control Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

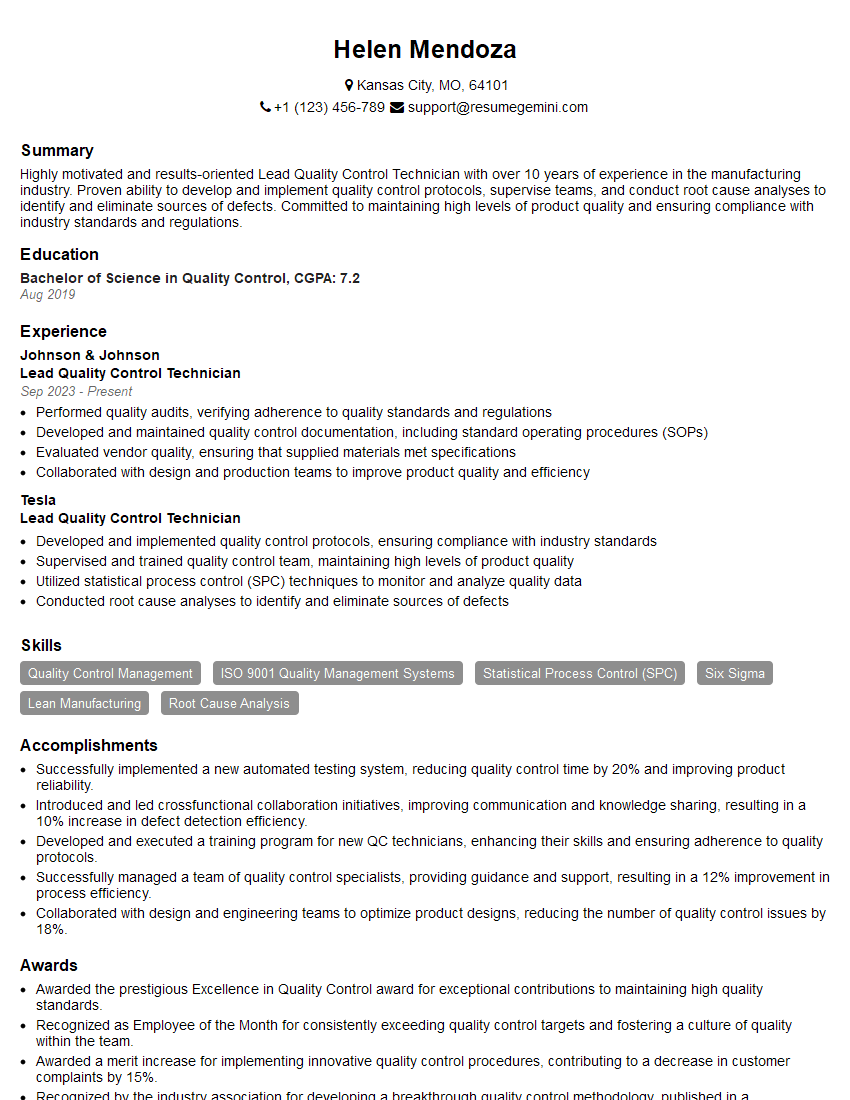

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Quality Control Technician

1. Describe the key principles of quality control in the manufacturing industry?

- Prevention: Implementing measures to prevent defects from occurring in the first place.

- Detection: Identifying and removing defective products before they reach customers.

- Correction: Taking corrective actions to resolve identified defects and prevent their recurrence.

- Continuous Improvement: Regularly reviewing and optimizing quality control processes to enhance effectiveness.

2. What are the different types of quality control inspections and when are they typically used?

Pre-production Inspection

- Verify materials, components, and equipment meet specifications.

- Detect any potential issues before production begins.

In-process Inspection

- Monitor production processes and identify non-conforming products.

- Prevent defective products from moving to subsequent stages.

Final Inspection

- Ensure finished products meet quality standards.

- Verify compliance with customer specifications and industry regulations.

3. How do you handle customer complaints related to product quality issues?

- Acknowledge and apologize: Respond promptly and empathetically, even if the complaint is unfounded.

- Gather information: Collect details about the issue, including product details, batch numbers, and customer observations.

- Conduct investigation: Analyze the complaint and identify the root cause of the issue.

- Resolve complaints: Offer solutions such as product replacements, refunds, or technical support.

- Follow up: Stay in touch with the customer to ensure their satisfaction and prevent similar issues in the future.

4. What are the key performance indicators (KPIs) you use to measure the effectiveness of quality control processes?

- Defect rate: Number of defective products produced per unit of production.

- Customer satisfaction: Number of customer complaints or positive feedback related to product quality.

- Process yield: Percentage of products passing quality inspections.

- First pass yield: Percentage of products passing inspection on the first attempt.

- Downtime due to quality issues: Amount of production time lost due to detection and correction of defects.

5. Describe the role of statistical process control (SPC) in quality control.

- Monitor and analyze process data: Collect and analyze data to identify trends and variations.

- Detect and prevent process deviations: Identify deviations from normal operating conditions and take corrective actions.

- Control and improve processes: Use SPC techniques such as control charts to adjust and optimize production processes.

- Reduce product variability and improve quality: Minimize variations and ensure consistent product quality.

6. How do you stay updated on the latest quality control techniques and industry best practices?

- Attend industry conferences and seminars: Participate in events to learn about emerging technologies and methodologies.

- Read technical journals and publications: Stay informed about technical advancements and research findings.

- Connect with quality control professionals: Network with experts to exchange knowledge and best practices.

- Pursue professional certifications: Obtain certifications such as Certified Quality Inspector (CQI) or Six Sigma Black Belt to demonstrate competence.

7. Describe a situation where you implemented a quality improvement initiative and the results you achieved.

- Problem Identification: Identified a high defect rate in a specific product line.

- Root Cause Analysis: Conducted an SPC analysis to determine that a supplier was providing substandard materials.

- Solution Implementation: Replaced the supplier with a more reliable one and implemented stricter incoming material inspections.

- Results: Reduced the defect rate by 50% and significantly improved product quality.

8. How do you prioritize quality control activities when facing resource constraints?

- Conduct risk assessment: Identify areas with the highest potential for quality issues and allocate resources accordingly.

- Optimize inspection processes: Implement lean techniques to reduce inspection times and improve efficiency.

- Delegate tasks: Empower team members to take on quality control responsibilities, freeing up time for high-priority tasks.

- Utilize technology: Leverage automated inspection systems and data analytics tools to increase efficiency.

9. How do you handle non-conforming products?

- Identify and quarantine: Segregate non-conforming products to prevent their release.

- Investigate and document: Determine the cause of the non-conformance and document the findings.

- Take corrective actions: Implement measures to prevent the recurrence of non-conformance, such as adjusting production processes or training employees.

- Dispose or rework: If the products cannot be repaired or reworked, they are disposed of according to established procedures.

10. What are the key challenges you have faced in previous quality control roles and how did you overcome them?

- Challenge: Implementing a new quality management system

Overcoming: Led a team to conduct extensive research, develop a customized system, and train staff on its implementation. - Challenge: Meeting increasing production demands without compromising quality

Overcoming: Developed and implemented lean manufacturing techniques to streamline processes and reduce cycle time. - Challenge: Managing multiple quality control projects simultaneously

Overcoming: Used project management tools and effective delegation to prioritize tasks and meet deadlines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Quality Control Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Quality Control Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Lead Quality Control Technician

Lead Quality Control Technicians are responsible for overseeing the entire quality control process within a manufacturing or production environment. They are responsible for developing, implementing, and maintaining quality standards, as well as inspecting, testing, and verifying the quality of products or services.

1. Developing and Implementing Quality Standards

Lead Quality Control Technicians work with other members of the quality control team to develop and implement quality standards. These standards may include specifications for raw materials, finished products, and processes. They also work with suppliers to ensure that materials and components meet the required standards.

2. Inspecting and Testing Products and Services

Lead Quality Control Technicians inspect and test products and services to ensure that they meet the required quality standards. They use a variety of tools and techniques to conduct inspections, including visual inspections, dimensional measurements, and functional testing.

3. Verifying the Quality of Products and Services

Lead Quality Control Technicians verify the quality of products and services by reviewing inspection and test results. They also audit quality control processes to ensure that they are being followed correctly. They may also work with customers to resolve any quality issues.

4. Training and Supervising Quality Control Personnel

Lead Quality Control Technicians train and supervise other quality control personnel. They may also be responsible for developing and implementing quality control training programs.

Interview Tips for Lead Quality Control Technician Candidates

Preparing for an interview for a Lead Quality Control Technician position requires thorough knowledge of the job responsibilities, as well as the ability to demonstrate your skills and experience in this area. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Before the interview, research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position.

2. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the position. Focus on your ability to develop and implement quality standards, inspect and test products and services, and verify the quality of products and services.

3. Use Specific Examples

When answering interview questions, use specific examples to demonstrate your skills and experience. For example, you might describe a time when you developed a new quality control process that improved the quality of a product.

4. Prepare Questions for the Interviewer

At the end of the interview, be sure to prepare questions for the interviewer. This shows that you are interested in the position and that you are taking the interview seriously.

5. Follow Up After the Interview

After the interview, be sure to follow up with the interviewer. This could involve sending a thank-you note or calling to inquire about the status of your application.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lead Quality Control Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!