Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lead Vulcanizing Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

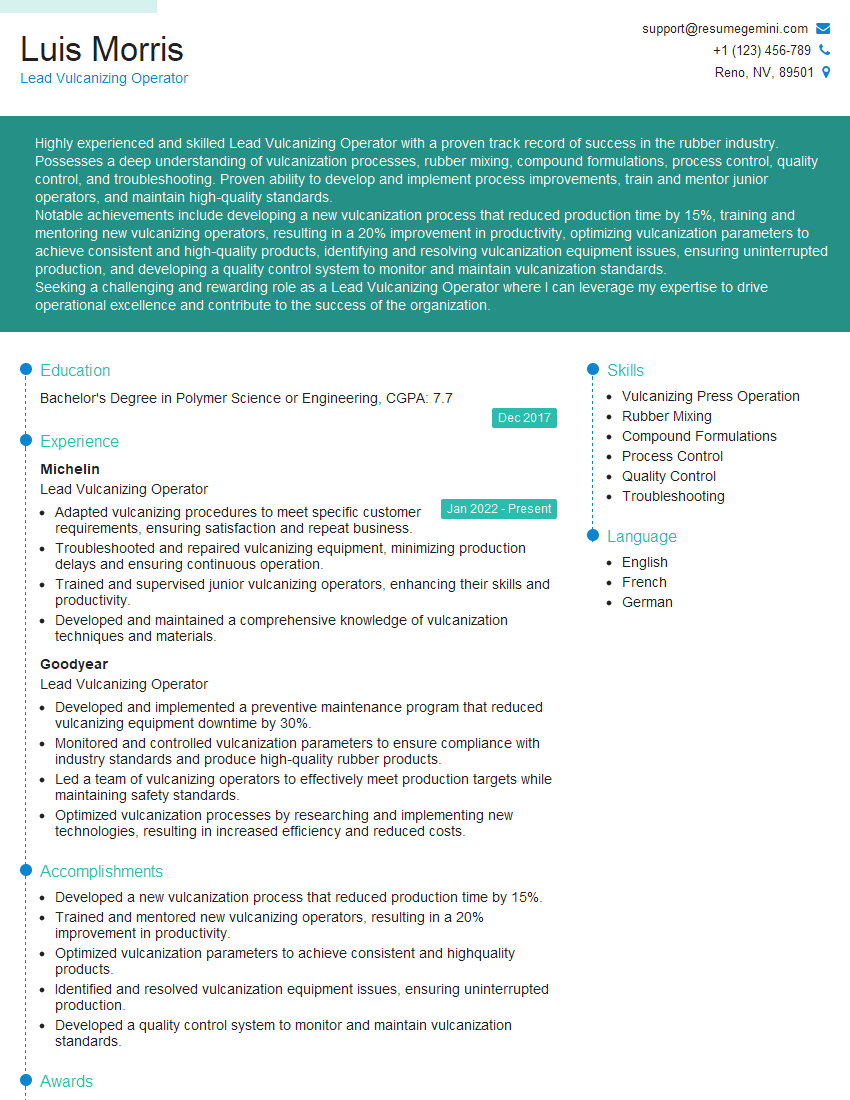

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Vulcanizing Operator

1. What are the key responsibilities of a Lead Vulcanizing Operator?

As a Lead Vulcanizing Operator, my primary responsibilities include:

- Supervising and directing a team of vulcanizing operators

- Ensuring the efficient and safe operation of vulcanizing equipment

- Monitoring the vulcanization process and making adjustments as needed

- Inspecting vulcanized products for quality and adherence to specifications

- Performing maintenance and repairs on vulcanizing equipment

- Training and mentoring new vulcanizing operators

- Maintaining a clean and organized work area

- Following all safety procedures and regulations

2. Describe the vulcanization process and its importance in manufacturing?

Key Steps of Vulcanization Process

- Preparation of raw materials

- Mixing of rubber compounds

- Molding or shaping of rubber products

- Application of heat and pressure (vulcanization)

Importance of Vulcanization

- Improves mechanical properties (strength, durability, elasticity)

- Enhances resistance to heat, chemicals, and aging

- Allows for a wide range of applications in various industries

3. What are the different types of vulcanization methods?

- Hot press vulcanization

- Steam autoclave vulcanization

- Continuous vulcanization (CV)

- Microwave vulcanization

- Radiation vulcanization

4. How do you ensure the quality of vulcanized products?

- Visual inspection for defects and imperfections

- Dimensional checks to verify product specifications

- Mechanical testing (e.g., tensile strength, elongation at break)

- Chemical testing to analyze rubber composition and properties

5. What are the safety precautions that must be followed during vulcanization operations?

- Wearing appropriate personal protective equipment (PPE)

- Following proper handling procedures for chemicals and materials

- Maintaining a clean and well-ventilated work area

- Adhering to established operating procedures

- Reporting any accidents or incidents promptly

6. How do you handle process deviations or equipment malfunctions during vulcanization?

- Identify the root cause of the deviation or malfunction

- Take immediate action to correct the issue and prevent further defects

- Document the incident and implement corrective measures to avoid recurrence

- Inform supervisors and maintenance personnel as necessary

7. What are your strategies for optimizing the efficiency and productivity of the vulcanization process?

- Regular equipment maintenance and calibration

- Proper training and supervision of operators

- Utilization of lean manufacturing techniques (e.g., 5S, kaizen)

- Continuous process monitoring and data analysis

- Collaboration with other departments (e.g., production planning, quality control)

8. How do you stay updated on the latest advancements and best practices in vulcanization technology?

- Attending industry conferences and workshops

- Reading technical journals and industry publications

- Seeking out training and certification programs

- Networking with professionals in the field

9. Describe a challenging situation you faced as a Vulcanizing Operator and how you overcame it.

In a previous role, we encountered a persistent issue with excessive scrap due to variations in the vulcanization process. To address this, I led a team to conduct a thorough investigation, identifying the contributing factors. We implemented several process improvements, including adjusting the cure time and temperature, optimizing equipment settings, and enhancing operator training. As a result, scrap rates were significantly reduced, leading to improved product quality and cost savings.

10. Why are you interested in this Lead Vulcanizing Operator position, and how do you believe your skills and experience align with our company’s needs?

I am highly motivated to join your organization as a Lead Vulcanizing Operator. My proven expertise in vulcanizing operations, coupled with my strong leadership skills and commitment to quality, make me an ideal candidate for this role. I am confident that I can leverage my experience to optimize your vulcanization process, deliver exceptional product quality, and contribute to your company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Vulcanizing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Vulcanizing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lead Vulcanizing Operator plays a critical role in manufacturing processes, managing a team and ensuring efficient and high-quality production of vulcanized rubber products. Key job responsibilities include:

1. Production Management

Oversees the production process, ensuring adherence to established procedures and quality standards. Monitors production schedules, coordinates with team members, and makes adjustments as needed to optimize efficiency and meet targets.

2. Team Leadership

Leads a team of Vulcanizing Operators, providing guidance, support, and training. Assigns tasks, monitors performance, and provides feedback to enhance productivity and maintain a positive work environment.

3. Equipment Operation

Operates and maintains vulcanizing equipment, including autoclaves, presses, and curing chambers. Ensures proper setup and calibration of equipment to achieve the desired product specifications.

4. Quality Control

Inspects vulcanized products for quality, ensuring adherence to specifications. Conducts tests, such as tensile strength, elongation, and hardness, to verify product integrity and meet customer requirements.

5. Process Improvement

Identifies opportunities for process optimization and implements improvements to enhance efficiency, reduce waste, and increase productivity. Collaborates with engineers and other stakeholders to develop and implement cost-effective solutions.

Interview Tips

To ace the interview for a Lead Vulcanizing Operator position, follow these tips:

1. Prepare for Technical Questions

Research common technical questions related to vulcanization processes, equipment operation, and quality control. Study the company’s website and industry-specific publications to gain insights into their specific practices.

2. Highlight Leadership Experience

Emphasize your ability to lead a team effectively. Provide examples of how you have motivated, coached, and mentored team members to achieve goals. Quantify your accomplishments whenever possible.

3. Demonstrate Problem-Solving Skills

Describe instances where you identified and resolved production issues. Explain the steps you took, the solutions you implemented, and the positive outcomes achieved. This demonstrates your analytical and problem-solving abilities.

4. Showcase Process Improvement Initiatives

Highlight any initiatives you have led or participated in to improve production processes. Explain how your suggestions resulted in increased efficiency, reduced downtime, or improved product quality.

5. Emphasize Safety and Compliance

Emphasize your commitment to safety and regulatory compliance. Explain how you have implemented safety protocols and ensured the proper use of equipment to maintain a safe and compliant work environment.

6. Research the Company

Familiarize yourself with the company’s culture, values, and industry standing. This shows your genuine interest and eagerness to contribute to their team.

7. Practice Your Answers

Prepare for the interview by rehearsing your answers to common questions. This will boost your confidence and allow you to articulate your skills and experience more effectively.

8. Dress Professionally

Dress appropriately for the interview, as first impressions matter. Business attire is recommended to convey a sense of professionalism and respect.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lead Vulcanizing Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.