Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Leather Finisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

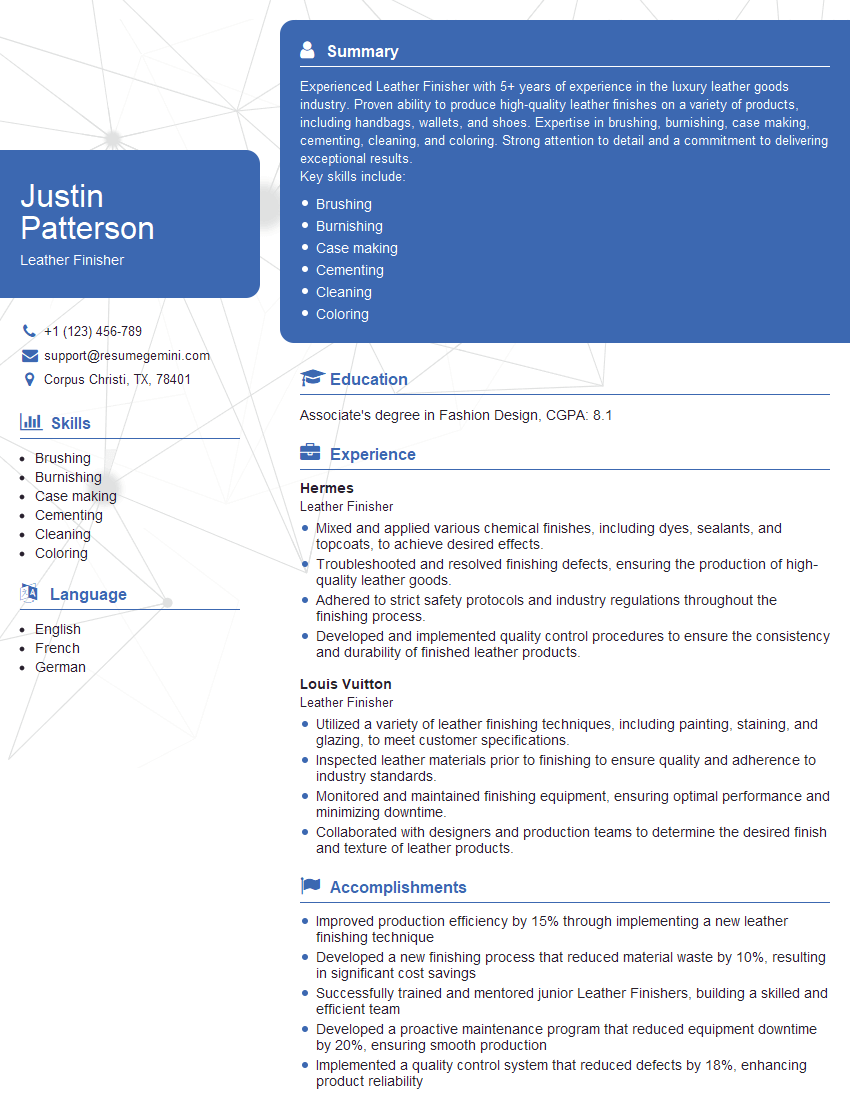

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Leather Finisher

1. What are the different types of leather finishes and how are they achieved?

– Embossed leather: This is a type of finish that creates a raised pattern on the leather. It is achieved by pressing the leather into a mold or die. – Printed leather: This is a type of finish that creates a design on the leather using ink or dyes. It can be done by hand or machine. – Painted leather: This is a type of finish that creates a solid color on the leather. It is achieved by applying paint to the leather and then allowing it to dry. – Metallic leather: This is a type of finish that gives the leather a metallic appearance. It is achieved by applying a metallic powder or paint to the leather. – Distressed leather: This is a type of finish that gives the leather a worn or aged appearance. It is achieved by sanding or rubbing the leather to create scuffs and scratches.

2. What are the different types of leather and how do they differ in their properties?

– Full-grain leather: This is the highest quality type of leather. It is made from the top layer of the hide and has all of the natural grain intact. – Top-grain leather: This type of leather is made from the second layer of the hide and has some of the natural grain removed. – Corrected-grain leather: This type of leather has the natural grain removed and is then embossed with a new pattern. – Split leather: This type of leather is made from the bottom layer of the hide and is less durable than other types of leather.

3. What are the different types of leather dyes and how are they applied?

– Acid dyes: These dyes are used to dye leather that has been tanned with acid. They are applied to the leather in a bath and then allowed to dry. – Basic dyes: These dyes are used to dye leather that has been tanned with basic chemicals. They are applied to the leather in a bath and then allowed to dry. – Direct dyes: These dyes are used to dye leather that has not been tanned. They are applied to the leather in a bath and then allowed to dry.

4. What are the different types of leather finishes and how are they achieved?

– Matte finish: This type of finish gives the leather a flat, non-reflective surface. It is achieved by applying a matte varnish or sealant to the leather. – Glossy finish: This type of finish gives the leather a shiny, reflective surface. It is achieved by applying a glossy varnish or sealant to the leather. – Satin finish: This type of finish gives the leather a soft, subtle sheen. It is achieved by applying a satin varnish or sealant to the leather.

5. What are the different types of leather conditioning products and how are they used?

– Leather cleaners: These products are used to clean leather and remove dirt and grime. They are typically applied to the leather with a cloth or sponge and then wiped off. – Leather conditioners: These products are used to condition leather and keep it soft and supple. They are typically applied to the leather with a cloth or sponge and then allowed to dry. – Leather protectors: These products are used to protect leather from water and stains. They are typically applied to the leather with a cloth or sponge and then allowed to dry.

6. What are the different types of leather repair products and how are they used?

– Leather fillers: These products are used to fill in holes and scratches in leather. They are typically applied to the leather with a spatula or brush and then allowed to dry. – Leather dyes: These products are used to dye leather and change its color. They are typically applied to the leather with a brush or sponge and then allowed to dry. – Leather sealants: These products are used to seal leather and protect it from water and stains. They are typically applied to the leather with a cloth or sponge and then allowed to dry.

7. What are the safety hazards associated with working with leather and how can they be prevented?

– Chemical hazards: Leather is treated with a variety of chemicals, which can be harmful if inhaled or ingested. These chemicals include dyes, finishes, and solvents. To prevent exposure to these hazards, it is important to wear a respirator and gloves when working with leather. – Physical hazards: Leather can be sharp and can cause cuts and abrasions. To prevent these injuries, it is important to wear gloves and safety glasses when working with leather. – Biological hazards: Leather can harbor bacteria and other microorganisms, which can cause infections. To prevent these infections, it is important to wash your hands thoroughly after working with leather.

8. What are the quality control procedures that you follow when finishing leather?

– Visual inspection: The leather is inspected for any defects, such as holes, scratches, or discoloration. – Physical testing: The leather is tested for its strength, durability, and flexibility. – Chemical testing: The leather is tested for its resistance to water, stains, and fading.

9. What are the different types of leather finishing equipment and how are they used?

– Embossing machines: These machines are used to create raised patterns on leather. – Printing machines: These machines are used to print designs on leather. – Painting machines: These machines are used to apply paint to leather. – Metallic coating machines: These machines are used to apply a metallic coating to leather. – Distressing machines: These machines are used to create a worn or aged appearance on leather.

10. What are the different types of leather finishing techniques and how are they used?

– Hand finishing: This technique involves using hand tools to finish leather. – Machine finishing: This technique involves using machines to finish leather. – Combination finishing: This technique involves using a combination of hand and machine finishing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Leather Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Leather Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Leather Finisher, you will be responsible for the final finishing touches on leather goods, ensuring their quality and aesthetic appeal. Your key responsibilities include:

1. Leather Preparation

Inspecting and preparing leather surfaces for finishing, removing any imperfections or blemishes.

- Smoothing out leather surfaces using sanding or buffing techniques.

- Applying protective coatings to prevent damage and enhance durability.

2. Dyeing and Coloring

Applying dyes and pigments to leather to achieve the desired color and finish.

- Experimenting with different dyeing techniques to create unique effects and patterns.

- Matching colors accurately to meet customer specifications.

3. Embossing and Detailing

Embossing or engraving designs and patterns into leather for added depth and texture.

- Using heat or pressure to create raised or recessed designs.

- Adding intricate details, such as stitching, studs, or embellishments.

4. Finishing and Polishing

Applying final finishes to leather to enhance its appearance and protect its surface.

- Buffing and polishing leather to achieve a desired sheen or texture.

- Applying protective coatings to prevent fading, scratching, or staining.

Interview Tips

To ace your interview for a Leather Finisher position, follow these tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Leather Finisher position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the role.

2. Highlight Your Skills and Experience

In your resume and during the interview, emphasize your technical skills as a Leather Finisher, such as dyeing, embossing, and finishing techniques. Quantify your experience whenever possible, providing specific examples of your accomplishments.

3. Be Prepared to Demonstrate Your Creativity

Leather Finishing often involves a creative element. Prepare examples of your work, such as a portfolio or samples, to showcase your artistic abilities and attention to detail. Discuss how you incorporate creativity into your finishing process.

4. Ask Informed Questions

asking thoughtful questions during the interview shows your interest and engagement in the position. Prepare questions about the company’s production process, quality control standards, and opportunities for professional development.

5. Dress Professionally

First impressions matter. Dress professionally for the interview, as it demonstrates respect for the company and the position. Consider wearing dark-colored, clean clothing that allows you to move comfortably.

6. Be Punctual

Punctuality shows respect for the interviewer’s time. Plan your route in advance and arrive at the interview location on time, or slightly early. This demonstrates your organizational skills and reliability.

7. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. This will help you articulate your thoughts clearly and concisely during the interview.

8. Confidence and Enthusiasm

Show confidence in your abilities and enthusiasm for the position. Be yourself, but project a positive and professional demeanor throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Leather Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!