Are you gearing up for a career in Lehr Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lehr Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

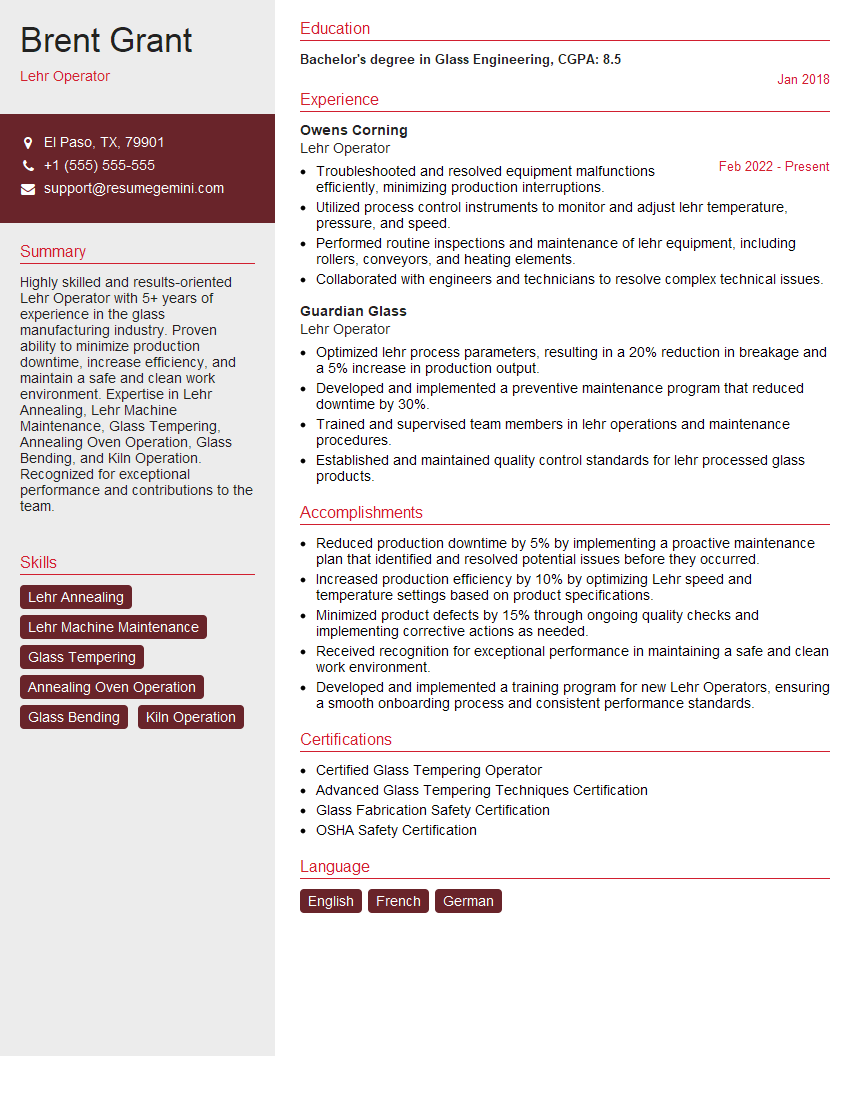

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lehr Operator

1. What is the purpose of a lehr and how does it work?

The purpose of a lehr is to gradually cool glass products after they have been formed. This controlled cooling process is necessary to prevent the glass from cracking or warping due to thermal stress. The lehr consists of a long tunnel with several temperature zones. The glass products are conveyed through the tunnel, and the temperature is gradually decreased as they move along. This slow cooling process allows the glass to anneal, which means that the internal stresses are relieved.

2. What are the different types of lehrs, and what are their advantages and disadvantages?

Batch Lehr

- Advantages:

- Can handle a wide variety of glass products

- Relatively low initial cost

- Disadvantages:

- Less efficient than continuous lehrs

- Can be difficult to maintain consistent temperatures

Continuous Lehr

- Advantages:

- More efficient than batch lehrs

- Easier to maintain consistent temperatures

- Disadvantages:

- Cannot handle as wide a variety of glass products as batch lehrs

- Higher initial cost

Shuttle Lehr

- Advantages:

- Combines the advantages of batch and continuous lehrs

- Flexibility to switch between different types of glass products

- Disadvantages:

- More complex to operate than batch or continuous lehrs

- Higher maintenance costs

3. How do you monitor and control the temperature inside a lehr?

The temperature inside a lehr is monitored and controlled using thermocouples. Thermocouples are devices that convert a temperature difference into an electrical signal. The thermocouples are placed at strategic locations throughout the lehr, and they transmit their signals to a computer. The computer uses this information to control the lehr’s heating and cooling systems, ensuring that the temperature remains within the desired range.

4. What are the safety precautions that must be taken when operating a lehr?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hard hat.

- Be aware of the location of all emergency exits and fire extinguishers.

- Do not enter the lehr unless it is properly ventilated.

- Never touch the hot glass products inside the lehr.

- Be aware of the potential for steam and condensation inside the lehr.

- Follow all manufacturer’s instructions for operating the lehr.

5. What are the common problems that can occur with a lehr, and how do you troubleshoot them?

- Problem: The glass products are not annealing properly.

- Possible causes: The lehr temperature is too high, the cooling rate is too fast, or the lehr is not properly ventilated.

- Troubleshooting steps: Check the lehr temperature and cooling rate, and make sure that the lehr is properly ventilated.

- Problem: The glass products are cracking.

- Possible causes: The lehr temperature is too high, the cooling rate is too fast, or the glass products have been exposed to thermal shock.

- Troubleshooting steps: Check the lehr temperature and cooling rate, and make sure that the glass products have not been exposed to thermal shock.

- Problem: The lehr is not heating up properly.

- Possible causes: The heating elements are not working, the temperature controller is not functioning properly, or the lehr has a gas leak.

- Troubleshooting steps: Check the heating elements, the temperature controller, and the lehr for gas leaks.

6. How do you maintain a lehr to ensure that it is operating efficiently and safely?

- Inspect the lehr regularly for any signs of damage or wear.

- Clean the lehr regularly to remove any dust or debris that could accumulate.

- Calibrate the lehr’s temperature controller on a regular basis.

- Lubricate the lehr’s moving parts regularly.

- Follow all manufacturer’s instructions for maintaining the lehr.

7. What are the different types of glass products that can be processed in a lehr?

- Float glass

- Container glass

- Automotive glass

- Pharmaceutical glass

- Specialty glass products

8. What are the key factors that affect the quality of the glass products that are processed in a lehr?

- The lehr temperature

- The cooling rate

- The ventilation of the lehr

- The type of glass product

- The condition of the lehr

9. What are the potential environmental impacts of a lehr, and how can they be minimized?

- Air pollution: Lehrs can emit pollutants such as nitrogen oxides, sulfur oxides, and particulate matter. These pollutants can be minimized by using low-NOx burners and by installing pollution control equipment.

- Water pollution: Lehrs can also generate wastewater. This wastewater can be minimized by using water-saving technologies and by treating the wastewater before it is discharged.

- Energy consumption: Lehrs are energy-intensive processes. The energy consumption of a lehr can be minimized by using energy-efficient technologies and by optimizing the lehr’s operating conditions.

10. What are the latest trends in lehr technology?

- The use of computer-controlled lehrs

- The development of more energy-efficient lehrs

- The use of lehrs to process new types of glass products

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lehr Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lehr Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lehr Operators play a crucial role in the manufacturing process of glass containers. They operate the Lehr, a specialized oven used to anneal glass products, ensuring their durability and preventing breakage.

1. Operating the Lehr

Lehr Operators are responsible for:

- Monitoring and controlling the Lehr’s temperature, ensuring accurate annealing.

- Loading and unloading glass containers onto and off the Lehr conveyor.

- Adjusting the Lehr’s speed and settings to optimize annealing results.

2. Quality Control

Lehr Operators ensure the quality of the annealed glass:

- Inspecting glass containers for defects, such as cracks, bubbles, or uneven thickness.

- Reporting any quality issues to supervisors.

3. Maintenance and Safety

Lehr Operators contribute to maintaining a safe and efficient work environment:

- Performing routine maintenance on the Lehr, such as cleaning and lubricating.

- Following safety protocols, including wearing protective gear and adhering to established procedures.

4. Communication and Teamwork

Lehr Operators effectively communicate and collaborate with:

- Superiors, providing updates on Lehr operations and any issues encountered.

- Other team members, ensuring smooth coordination during production.

Interview Tips

Preparing thoroughly for your interview as a Lehr Operator can significantly increase your chances of success.

1. Research the Company and Role

Familiarize yourself with the company’s operations, products, and values. Understand the specific responsibilities of a Lehr Operator within that organization.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on the latest trends in glass manufacturing.

2. Highlight Your Skills and Experience

Emphasize your technical skills relevant to the role, such as Lehr operation, quality control, and maintenance procedures. Quantify your accomplishments to demonstrate your impact.

- Use specific examples to illustrate how you successfully managed production outputs, ensured product quality, and resolved technical issues.

- Be prepared to discuss your knowledge of different types of Lehrs and their applications.

3. Demonstrate Safety and Attention to Detail

Lehr Operators play a critical role in ensuring safety and product quality. Highlight your commitment to following safety protocols and your meticulous attention to detail.

- Provide examples of how you have consistently maintained a safe and clean work environment.

- Explain how your keen eye for detail has helped you identify and resolve potential quality issues.

4. Practice Common Interview Questions

Review common interview questions, such as “Why are you interested in this role?” and “What are your strengths and weaknesses?” Prepare concise and well-thought-out answers.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Practice answering questions aloud to improve your confidence and delivery.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lehr Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.